In short, a honey refractometer is a specialized, portable instrument used by beekeepers to measure the moisture content of honey. Its primary purpose is to provide a precise reading that confirms whether the honey is sufficiently "cured" and ready for harvest, ensuring it will not ferment or spoil during storage.

The core function of a honey refractometer is to replace guesswork with data. It provides the definitive metric—water content—that determines the shelf stability and quality of honey, protecting the harvest from fermentation.

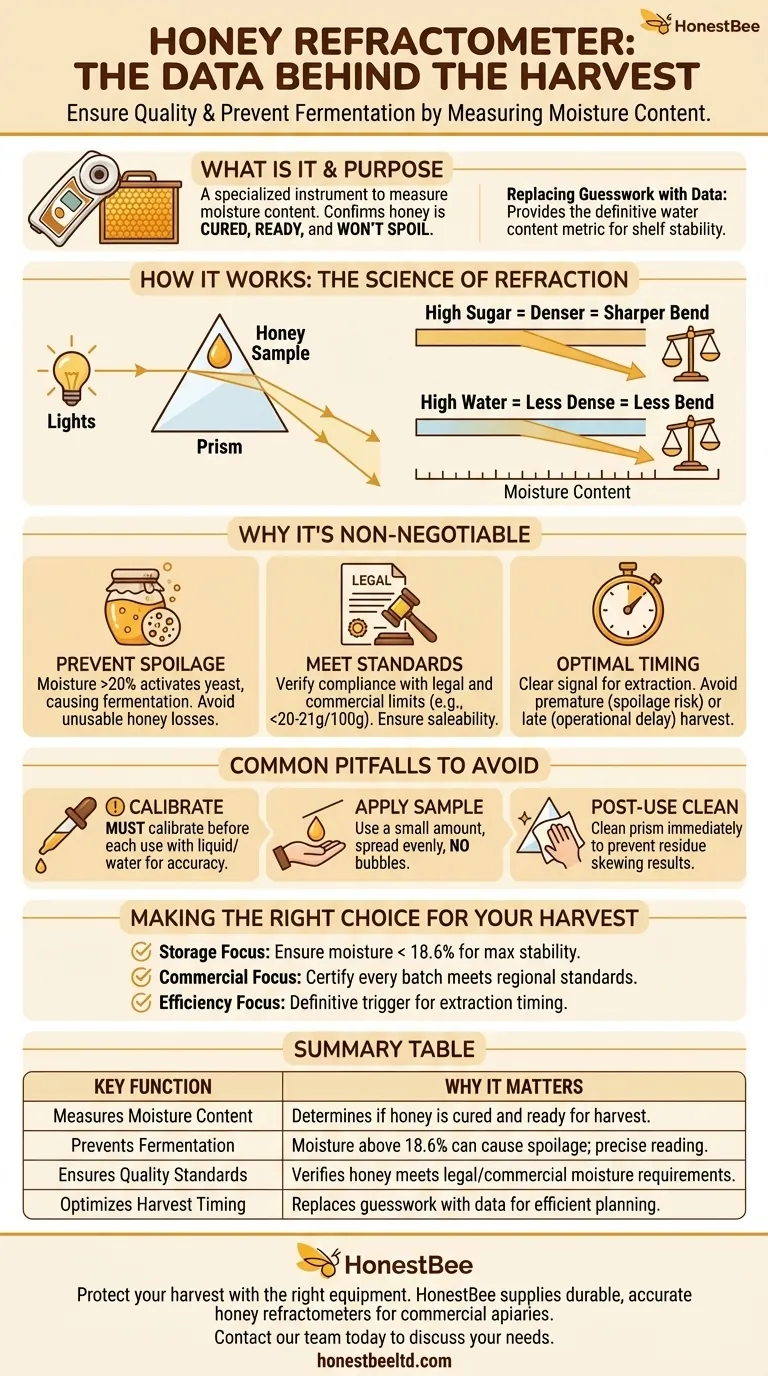

How a Refractometer Determines Water Content

A refractometer doesn't measure water directly. Instead, it measures how the concentration of sugar in the honey affects the behavior of light.

The Principle of Light Refraction

The device operates on the principle of refraction, which is the bending of light as it passes from one medium to another.

A prism inside the refractometer bends light passing through the honey sample. The angle of this bend is directly related to the density of the liquid.

From Sugar to Moisture

Honey with a high concentration of sugar (and other solids like pollen) is denser and will bend light more sharply.

Conversely, honey with a higher water content is less dense and bends light less. The refractometer's internal scale is calibrated to translate this angle of refraction into a simple, direct reading of moisture content.

Why Measuring Moisture is Non-Negotiable

Relying on visual cues alone to determine if honey is ready can be unreliable. A refractometer provides the certainty needed to maintain a high-quality product.

Preventing Fermentation and Spoilage

This is the most critical reason for measuring moisture. If the water content is too high (typically above 20%), naturally present yeasts can activate, causing the honey to ferment.

Fermented honey is unusable for most purposes and represents a significant loss of time and effort. A refractometer ensures the moisture level is low enough to prevent this.

Meeting Quality and Legal Standards

For commercial producers, honey quality is often legally defined by its composition. Many jurisdictions require honey to have a moisture content below a specific threshold to be sold.

For example, some standards mandate that moisture content must not exceed 20-21g per 100g. Using a refractometer is the simplest way to verify compliance.

Ensuring Optimal Extraction Timing

The refractometer provides a clear signal that honey is ready for extraction. This prevents the costly mistake of harvesting honey prematurely, which risks spoilage, or waiting too long, which can delay operations.

Common Pitfalls to Avoid

The accuracy of a refractometer depends entirely on proper usage. Ignoring these steps can lead to false readings and poor outcomes.

The Critical Step of Calibration

You must calibrate the device before each use. This simple step, usually done with a calibration liquid or distilled water, ensures the starting point for your measurement is accurate.

Applying the Honey Sample

Only a small amount of honey is needed. Place a drop on the prism and close the cover plate, ensuring the liquid spreads evenly without air bubbles or excess spilling over the sides.

Post-Use Cleaning

Always clean the prism and cover plate with a soft, damp cloth immediately after each use. Dried honey residue from a previous test will skew the results of your next measurement.

Making the Right Choice for Your Harvest

Using a refractometer allows you to make decisions based on precise data rather than intuition.

- If your primary focus is long-term storage and quality: Use the refractometer to ensure your honey's moisture content is safely below 18.6%, the widely accepted threshold for maximum stability.

- If your primary focus is commercial sales: Rely on the refractometer to certify that every batch meets or exceeds the legal and industry standards for moisture content in your region.

- If your primary focus is operational efficiency: Let the refractometer be the definitive trigger for when to begin extraction, eliminating the uncertainty of waiting for frames to be fully capped.

Ultimately, a honey refractometer transforms guesswork into certainty, giving you complete control over the quality and longevity of your harvest.

Summary Table:

| Key Function | Why It Matters |

|---|---|

| Measures Moisture Content | Determines if honey is cured and ready for harvest. |

| Prevents Fermentation | Moisture above 18.6% can cause spoilage; a refractometer provides a precise reading. |

| Ensures Quality Standards | Verifies honey meets legal and commercial moisture content requirements (often below 20%). |

| Optimizes Harvest Timing | Replaces guesswork with data for efficient extraction planning. |

Protect your harvest and ensure premium honey quality with the right equipment. HONESTBEE supplies durable, accurate honey refractometers and other essential beekeeping supplies to commercial apiaries and distributors through our wholesale-focused operations. Contact our team today to discuss your needs and ensure every batch meets the highest standards.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How should a honey refractometer be stored? Ensure Long-Term Accuracy and Protect Your Investment

- Why is an industrial-grade refractometer used to measure honey moisture? Ensure Stability and Prevent Fermentation

- Why is a handheld refractometer preferred for measuring nectar sugar? Expert Field Research Insights

- What is the technical significance of using a precision refractometer? Elevate Honey Purity and Quality Control

- How does a digital refractometer contribute to determining the quality and shelf life of honey? Master Honey Stability

- What is the role of an Abbe refractometer in the quality assessment of Thyme honey? Ensure Purity and Shelf Stability

- What is the specific function of a precision refractometer in assessing honey quality? Ensure Ripeness & Stability

- What role does the Abbe refractometer play in the quality assessment of honey? Ensure Stability and Purity