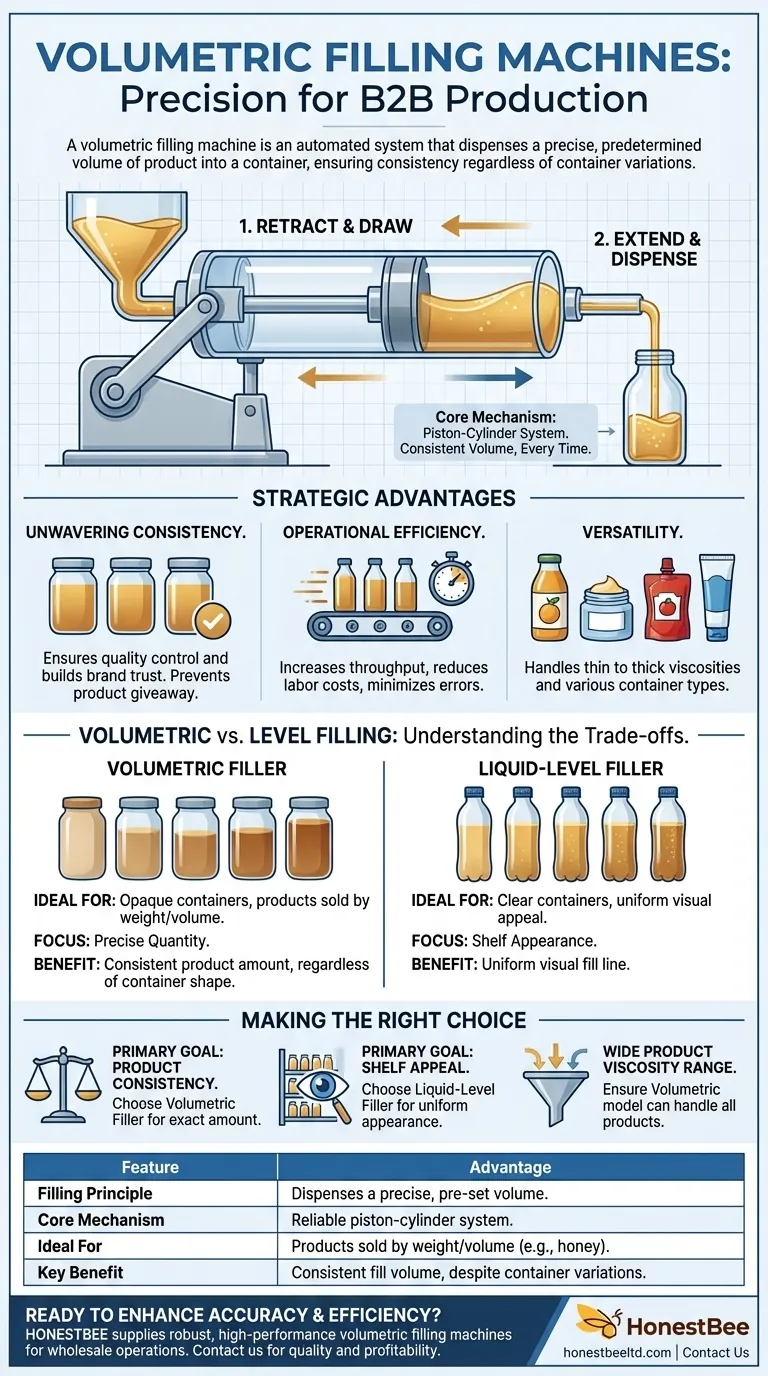

In short, a volumetric filling machine is an automated system designed to dispense a precise, predetermined volume of product into a container. It operates on the principle of measurement, ensuring that every container receives the exact same amount of product, such as honey, juice, or lotion. This method guarantees consistency by focusing on the quantity of the product itself, not the fill height within the container.

The core function of a volumetric filler is to ensure product consistency for quality control and cost management. It is the ideal solution when the exact amount of product in each package is more critical than achieving a uniform visual fill level across all containers.

How Volumetric Fillers Achieve Precision

A volumetric filler’s accuracy comes from its mechanical design, which is engineered to measure and dispense product with exceptional repeatability.

The Core Mechanism: The Piston Filler

Most volumetric fillers use a piston-cylinder system. Think of it like a large, precise medical syringe. The piston retracts, drawing a specific volume of product from a hopper into the cylinder. It then extends, dispensing that exact volume into the waiting container.

This simple, mechanical action is highly reliable and easy to calibrate, ensuring that the volume dispensed is consistent from the first container to the last.

Consistency Across All Containers

A key advantage of this method is its indifference to minor variations in container manufacturing. Because the machine dispenses a set volume, it doesn't matter if one glass jar is slightly thicker or a plastic tub is slightly deformed.

Each container receives the same amount of product, which is critical for products sold by weight or volume and for maintaining regulatory compliance.

The Strategic Advantages in Production

Choosing a volumetric filler has significant operational benefits beyond just accuracy. It is a strategic choice that impacts efficiency, flexibility, and quality.

Unwavering Product Consistency

By delivering a precise dose every time, these machines are foundational to quality control. This consistency builds brand trust with consumers who know they are getting the amount they paid for. It also prevents costly product giveaway.

Operational Efficiency

Automated and semi-automatic volumetric fillers significantly increase throughput compared to manual filling. They boost productivity, reduce the need for manual labor, and minimize human error, leading to lower operational costs.

Versatility in Products and Containers

These machines are highly flexible. They can be configured to handle a vast range of product viscosities, from thin juices and coffee creamers to thick sauces, creams, and syrups.

They are also compatible with many container types, including bottles, jars, yogurt cups, paint tins, and even toothpaste tubes. Some models can be adapted for heated, cooled, or foaming liquids.

Understanding the Trade-offs: Volumetric vs. Level Filling

The decision to use a volumetric filler is not universal. The primary alternative is a liquid-level filler, and the right choice depends entirely on your product and packaging goals.

When Volume is Non-Negotiable

A volumetric filler is the correct choice for opaque containers or for any product where the net weight or volume is the key selling point. It prioritizes the quantity of the product over its appearance in the package.

When Appearance is Key

A liquid-level filler, by contrast, fills every container to the same height. This is ideal for products in clear containers, like beverages, where a uniform fill line on the retail shelf is crucial for consumer perception of quality.

However, a level filler may result in slightly different volumes in each container due to small manufacturing imperfections. You might be giving away product in some containers to ensure others aren't underfilled.

Making the Right Choice for Your Goal

To select the right technology, you must first define your primary objective for the filling process.

- If your primary focus is product consistency and cost control: A volumetric filler is the definitive choice for ensuring every package has the correct amount.

- If your primary focus is shelf appeal for a product in a clear container: You should evaluate a liquid-level filler to guarantee a uniform visual appearance.

- If you handle a wide range of product viscosities: Confirm that the specific volumetric model you choose is engineered to accurately handle both your thinnest and thickest products.

Ultimately, understanding the fundamental difference between filling to a volume versus filling to a level empowers you to make the most effective choice for your production line.

Summary Table:

| Feature | Advantage |

|---|---|

| Filling Principle | Dispenses a precise, pre-set volume of product. |

| Core Mechanism | Reliable piston-cylinder system (like a syringe). |

| Ideal For | Products sold by weight/volume (e.g., honey, sauces, lotions). |

| Key Benefit | Consistent fill volume regardless of container shape variations. |

Ready to enhance your production line's accuracy and efficiency?

For commercial apiaries and beekeeping equipment distributors, precise honey filling is critical for quality and profitability. HONESTBEE supplies robust, high-performance volumetric filling machines and other essential beekeeping equipment through our wholesale-focused operations.

Contact us today to discuss how our filling solutions can help you control costs, ensure product consistency, and scale your operations.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

People Also Ask

- How do automated honey filling machines meet modern market trends? Elevate Your Brand with Precision and Safety

- How do professional honey-filling machines address the physical properties of honey? Ensure Quality Packaging

- What are the causes and solutions for a honey stick machine overheating? Expert Troubleshooting Guide

- When is a pump filling machine the ideal choice for filling honey? Boost Efficiency and Scalability for Your Apiary

- How do industrial honey-filling machines contribute to the value chain? Unlock Commercial Success for Bee Products

- What is the advantage of the mini filling machine's compact size? Unlock Operational Flexibility and Save Space

- Can honey filling machines be used to fill cosmetic products? Maximize Your Filling Line's Versatility

- What functions do specialized honey-filling machines perform? Maximize Post-Harvest Efficiency & Purity