At its core, heat treatment for honey is the controlled process of raising honey's temperature to achieve a specific outcome. These outcomes primarily include liquefying crystallized honey for easier handling, reducing its moisture content to prevent fermentation, and pasteurizing it to delay future crystallization for a longer shelf life. The exact temperature and duration are critical, as excessive heat can damage the honey's natural enzymes, flavor, and color.

Heating honey is a balancing act between achieving processability and preserving its delicate, natural qualities. The correct method is not a one-size-fits-all solution; it depends entirely on your goal, from simply re-liquefying a single jar to preparing a large batch for long-term commercial storage.

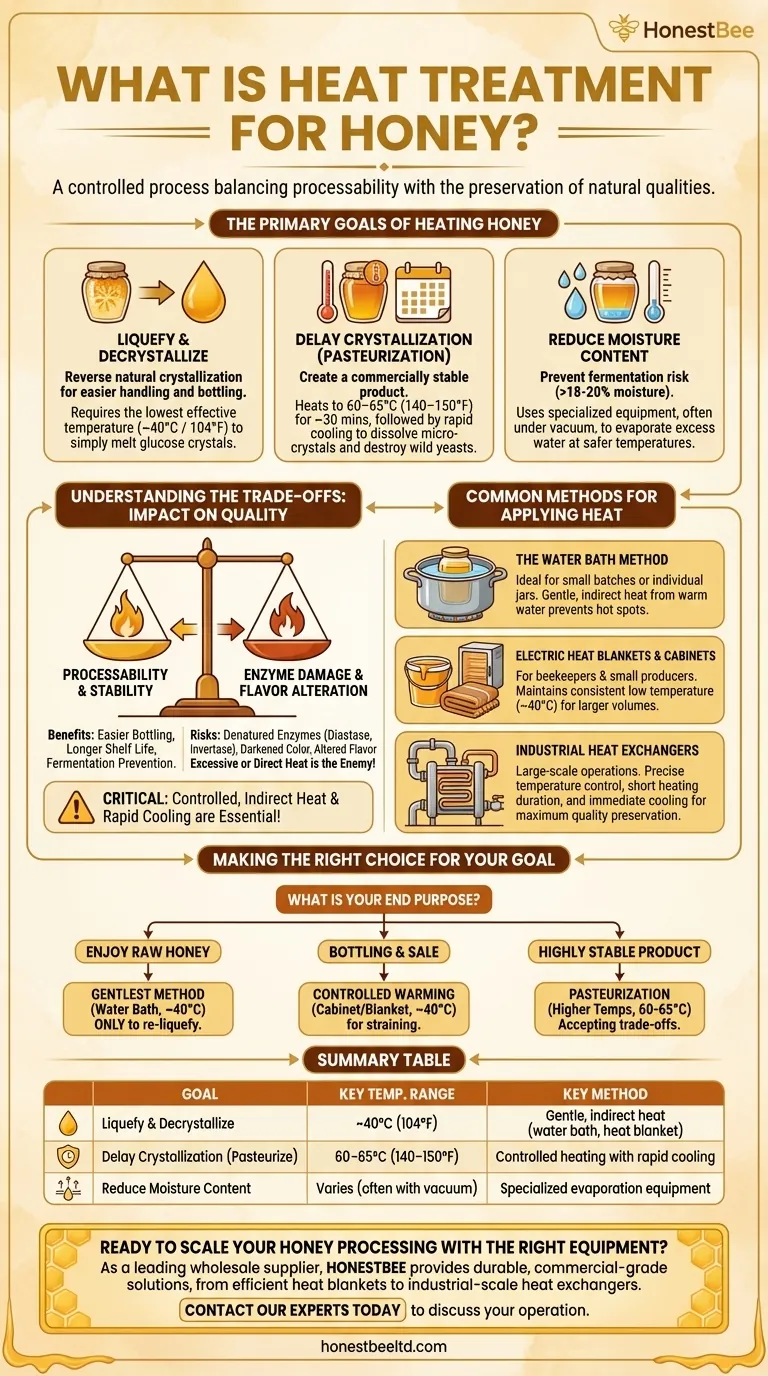

The Primary Goals of Heating Honey

Understanding why honey is heated is the first step in doing it correctly. Each goal requires a different approach to temperature and equipment.

To Liquefy and Decrystallize

Crystallization is a natural process that occurs in most raw honey. Gentle heat is the most effective way to reverse this process, returning the honey to a liquid state for bottling or consumption.

This process requires the lowest effective temperature to avoid damaging the honey. The goal is simply to melt the glucose crystals that have formed.

To Delay Future Crystallization (Pasteurization)

For a commercially stable product that remains liquid on the shelf, a more intense heat treatment is used. This process, a form of pasteurization, involves heating honey to a higher temperature to dissolve micro-crystals and destroy wild yeasts.

A conventional industrial process involves heating honey to 60–65°C (140–150°F) for about 30 minutes, followed by rapid cooling. This significantly slows the rate of future crystallization.

To Reduce Moisture Content

Honey with a moisture content above 18-20% is at risk of fermenting. Heat can be used to evaporate this excess water, ensuring the honey is stable for long-term storage.

This is often done using specialized equipment that increases the honey's surface area, such as rotating discs or cones, sometimes within a vacuum to allow for evaporation at lower, safer temperatures.

Understanding the Trade-offs: Heat's Impact on Quality

Applying heat is not without consequences. The benefits of processability and stability must be weighed against the potential damage to the honey's unique characteristics.

The Risk to Enzymes and Beneficial Compounds

Honey contains natural enzymes, such as diastase and invertase, which are indicators of its freshness and quality. These enzymes are sensitive to heat and can be denatured or destroyed by high temperatures, diminishing the honey's "raw" properties.

The Effect on Color and Flavor

Excessive or prolonged heat can alter the delicate flavor profile of honey and cause it to darken. This is why indirect heat and rapid cooling are key principles in professional processing—they minimize the time the honey spends at a damaging temperature.

The Importance of Temperature Control

The line between beneficial warming and harmful overheating is thin. Direct heat is the primary enemy, as it can easily scorch the honey. Controlled, gentle heating methods are essential to preserve quality.

Common Methods for Applying Heat

The right tool for the job depends on your scale and your specific goal.

The Water Bath Method

For small batches or individual jars, a water bath is the ideal method. By placing the honey container in a pot of warm (not boiling) water, you provide gentle, indirect heat that evenly liquefies the honey without creating hot spots.

Electric Heat Blankets and Cabinets

For beekeepers and small producers, electric heat blankets that wrap around buckets or warming cabinets are effective tools. They are designed to maintain a consistent, low temperature (e.g., 40°C / 104°F) over time, making it easy to liquefy and process larger volumes of crystallized honey.

Industrial Heat Exchangers

In large-scale commercial operations, honey is pumped through tubular heat exchangers. This allows for precise temperature control and a very short heating duration, followed by an immediate cooling phase to best protect the honey's natural characteristics while achieving pasteurization.

Making the Right Choice for Your Goal

Your approach to heating honey should be dictated by your end purpose.

- If your primary focus is simply enjoying raw honey: Use the most gentle method possible, like a warm water bath, only when you need to re-liquefy a crystallized jar.

- If your primary focus is preparing honey for bottling and sale: Use a controlled warming cabinet or heat blanket to bring honey to a workable temperature (around 40°C / 104°F) for straining and bottling while minimizing enzyme damage.

- If your primary focus is creating a highly stable product that will not crystallize: You will need to pasteurize at higher temperatures (around 60-65°C / 140-150°F), accepting the trade-off of altering the honey's raw properties.

Ultimately, treating honey with respect for its delicate composition is the key to preserving the quality and value of the final product.

Summary Table:

| Goal | Key Temperature Range | Key Method |

|---|---|---|

| Liquefy & Decrystallize | ~40°C (104°F) | Gentle, indirect heat (water bath, heat blanket) |

| Delay Crystallization (Pasteurize) | 60–65°C (140–150°F) | Controlled heating with rapid cooling |

| Reduce Moisture Content | Varies (often with vacuum) | Specialized evaporation equipment |

Ready to scale your honey processing with the right equipment?

As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, commercial-grade solutions you need. Whether you're looking for efficient heat blankets for your bottling line or exploring industrial-scale heat exchangers, we help you achieve your production goals while safeguarding honey quality.

Contact our experts today to discuss the best equipment for your operation and volume.

Visual Guide

Related Products

- HONESTBEE Commercial Upright Honey Melter

- Heavy Duty Stainless Steel Honey Processing Machine Decrystallizing Tank

- Honey Tank Heater Drum Heating Blanket for Honey Barrel

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- Why is a honey bucket warmer considered a valuable tool for honey storage? Preserve Quality & Streamline Bottling

- Why are specialized honey processing containers and packaging equipment critical? Boost Your Honey's Market Value

- How can honey processing equipment address consumer biases? Transform Crystallized Honey into Premium Creamed Products

- How many times can you decrystallize honey? The truth about quality loss with each cycle.

- How to fix solidified honey? A Beekeeper's Guide to Gentle Re-liquefaction