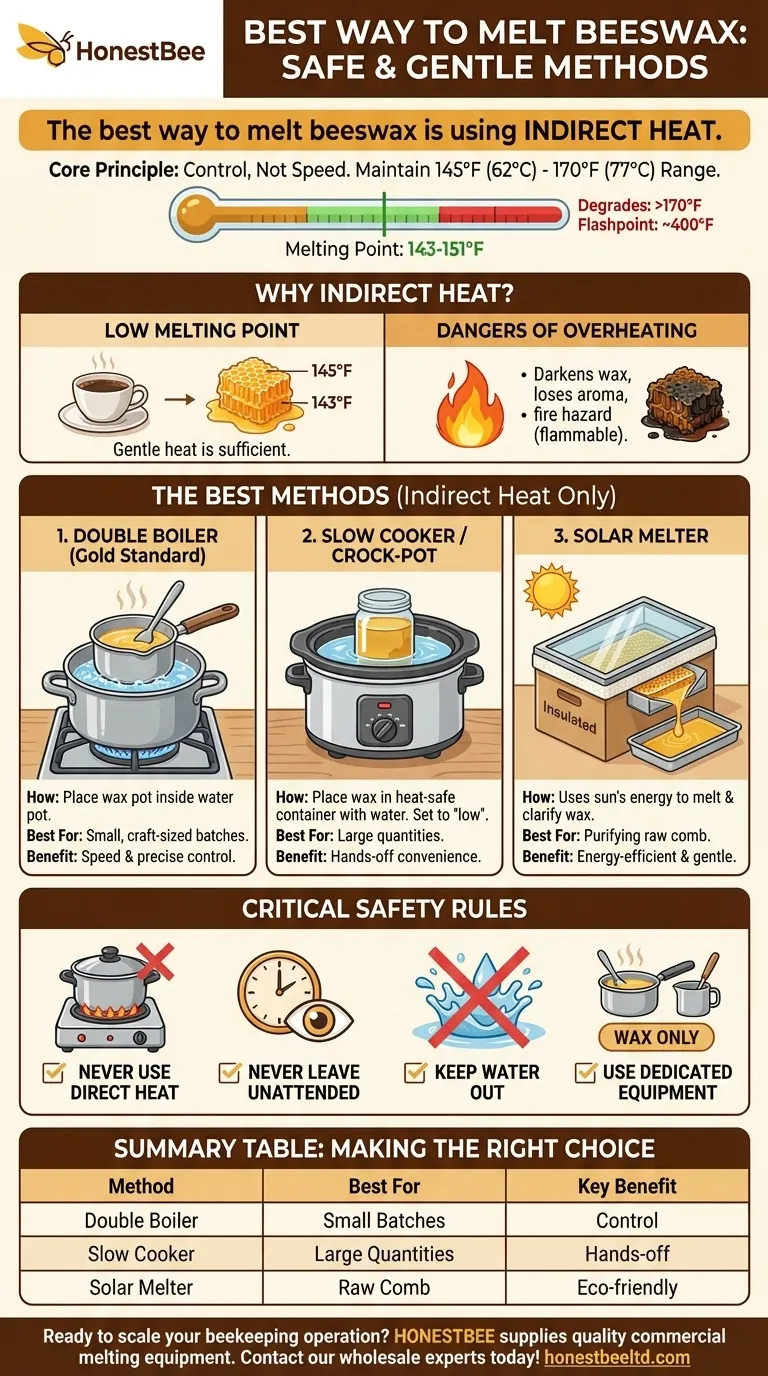

The best way to melt beeswax is to use a method that provides gentle, indirect heat, such as a double boiler or a dedicated slow cooker. These methods prevent the wax from overheating, which is critical because beeswax is flammable and can lose its desirable color and aroma if its temperature gets too high. Direct heat, like placing a pot of wax on a stove burner, should always be avoided.

The core principle of melting beeswax is not about speed, but control. The goal is to apply just enough indirect heat to bring the wax above its melting point (around 145°F / 62°C) without letting it exceed the temperature where it begins to degrade (around 170°F / 77°C).

Why Indirect Heat is Non-Negotiable

To handle beeswax properly, you must understand its two most important properties: its low melting point and its flammability.

The Low Melting Point

Beeswax begins to melt between 143-151°F (61-66°C). This is a relatively low temperature, not far above the temperature of a hot cup of coffee.

This means you do not need intense, direct heat to get the job done. Gentle heat is more than sufficient.

The Dangers of Overheating

Heating beeswax above 170-175°F (77-80°C) will cause it to darken and lose its natural, subtle honey aroma.

More importantly, beeswax is a flammable substance. If its temperature approaches its flashpoint of around 400°F (204°C), it can ignite, creating a dangerous fire that is difficult to extinguish. Direct heat from a stove burner can create hot spots that easily and unpredictably reach this temperature.

The Best Methods for Melting Beeswax

The safest and most effective methods all rely on the principle of indirect heat. They create a buffer that ensures the wax melts slowly and evenly.

The Double Boiler Method (The Gold Standard)

This is the most common, reliable, and accessible method for melting beeswax. You can easily create a makeshift double boiler.

Simply place a small pot or heat-safe bowl containing the beeswax inside a larger pot filled with a few inches of simmering water. The steam from the water transfers gentle, even heat to the inner pot, melting the wax perfectly.

The Crock-Pot / Slow Cooker Method

A dedicated crock-pot or slow cooker is an excellent, hands-off option, especially for larger quantities of wax.

Place your beeswax in a heat-safe container (like a glass jar) inside the crock-pot. Add water to the crock-pot until it surrounds the container, set it to "low" or "warm," and let it melt slowly. This method provides very stable, low heat over a long period.

The Solar Melter Method

For beekeepers or those processing raw comb, a solar melter is an incredibly efficient and gentle option.

This device is essentially a dark, insulated box with a glass lid that uses the sun's energy to slowly melt wax. The melted wax drips through a filter, separating it from debris and clarifying it in the process.

Critical Safety Rules and Considerations

Ignoring safety when melting beeswax can lead to ruined materials, property damage, or injury. These rules are not optional.

Never Use Direct Heat

Do not place a pot containing beeswax directly on an electric coil or gas flame. The lack of temperature control makes it far too easy to scorch the wax and create a fire hazard.

Never Leave Melting Wax Unattended

Beeswax can melt faster than you think. A situation can become dangerous in minutes. Always stay present and monitor the process from start to finish.

Keep Water Out of the Wax

Water will not mix with the wax and will settle at the bottom. If this water becomes superheated under the wax, it can erupt, splattering hot wax. Ensure your wax is dry before melting and be careful not to splash water into the melting pot.

Use Dedicated Equipment

Beeswax is notoriously difficult to clean from pots and utensils. It's wise to have a dedicated pot and stirring tools that you use only for wax work.

Making the Right Choice for Your Project

Your ideal method depends on your specific goal and the amount of wax you are working with.

- If your primary focus is small, craft-sized batches: Use the double boiler method for its speed and control.

- If your primary focus is melting a large quantity with minimal effort: Use a dedicated crock-pot for its 'set it and forget it' convenience.

- If your primary focus is purifying raw comb from a beehive: A solar melter is the most gentle and energy-efficient choice.

By respecting the material and prioritizing controlled, indirect heat, you can melt beeswax safely and preserve all of its wonderful natural qualities.

Summary Table:

| Method | Best For | Key Benefit |

|---|---|---|

| Double Boiler | Small, craft-sized batches | Speed and precise control |

| Slow Cooker | Large quantities | Hands-off convenience |

| Solar Melter | Purifying raw comb | Energy-efficient and gentle |

Ready to scale your beekeeping operation? HONESTBEE supplies commercial apiaries and distributors with high-quality, durable melting equipment and beekeeping supplies designed for safety and efficiency. Let us help you streamline your wax processing—contact our wholesale experts today to discuss your needs!

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

People Also Ask

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers

- What are the safety precautions when working with melted beeswax? Prevent Burns and Fire Hazards

- What temperature range is considered gentle heat for melting beeswax? Preserve Aroma & Color