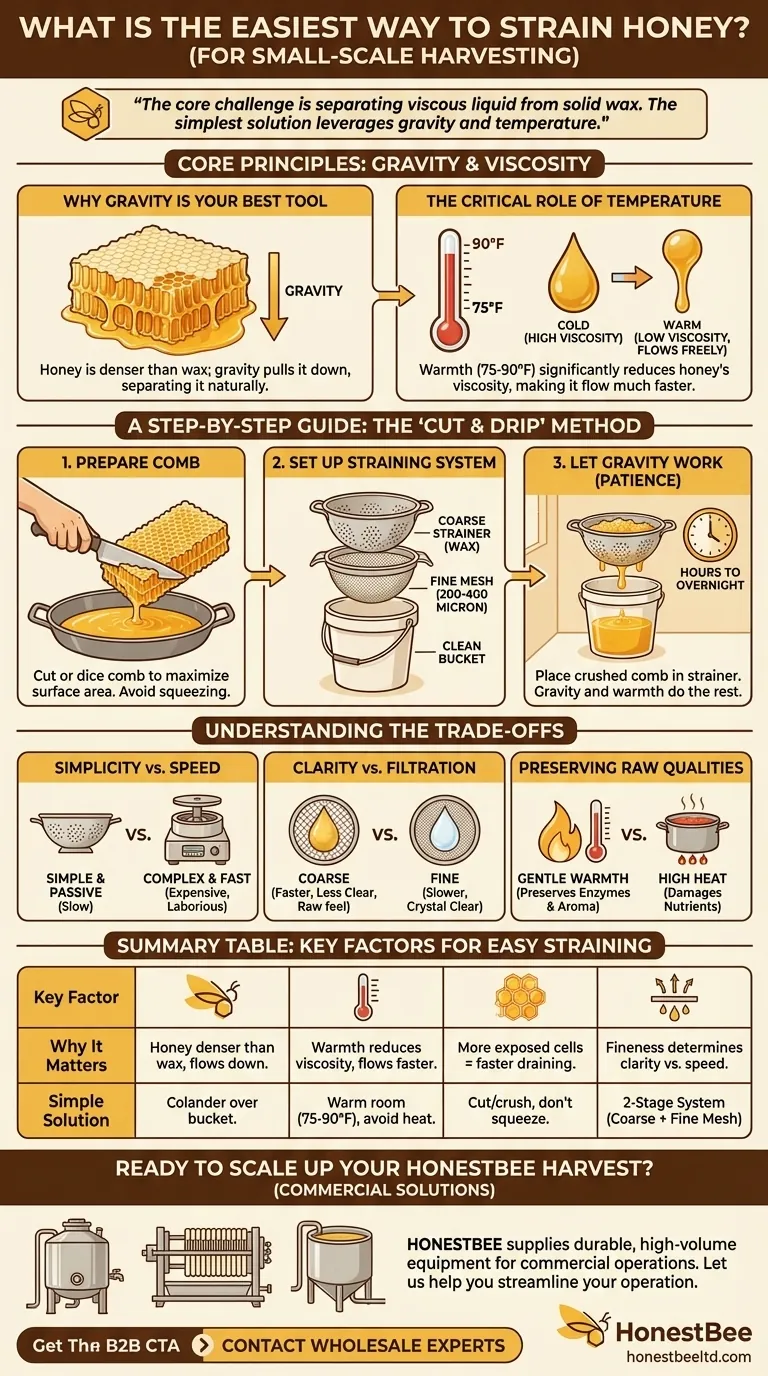

For small-scale harvesting, the easiest way to strain honey is to use a simple, gravity-fed setup. This involves placing crushed or diced honeycomb into a strainer or colander positioned over a food-safe container. By allowing the honey to drain naturally, often in a warm room, you can effectively separate it from the beeswax with minimal equipment and effort.

The core challenge of straining honey is separating a viscous liquid from solid wax. The simplest solution leverages gravity and temperature—crushing the comb to maximize surface area and letting the honey flow out on its own, a process made much faster with gentle warmth.

The Core Principle: Gravity and Viscosity

To strain honey effectively with minimal effort, you need to work with its physical properties, not against them. The entire process hinges on two key factors: gravity and viscosity.

Why Gravity Is Your Best Tool

Honey is significantly denser than beeswax. Given a path, gravity will naturally pull the liquid honey down and away from the lighter wax cappings and comb structure.

Your job is not to force the honey out, but simply to open the wax cells and let gravity do the work. This is the foundation of the simplest straining methods.

The Critical Role of Temperature

Honey is highly viscous, meaning it is thick and resists flowing. This viscosity is directly tied to temperature.

A small increase in temperature can dramatically decrease honey's viscosity, making it flow much more freely. Straining in a warm room (e.g., 75-90°F or 24-32°C) can reduce the draining time from days to hours. This is the principle behind commercial preheating, but applied on a simpler, safer scale that preserves the honey's raw qualities.

Maximizing Surface Area: Cut, Don't Squeeze

The final piece of the puzzle is exposing the honey to gravity. You achieve this by breaking open the sealed wax cells.

The most effective way is to cut or dice the comb into small pieces with a knife or use a cappings scratcher to crush it. This action creates a massive surface area for the honey to drain from. Avoid aggressively squeezing the comb, as this can force tiny wax particles and air into the honey, creating a cloudy emulsion that is difficult to clear.

A Step-by-Step Guide to the Easiest Method

This "cut and drip" technique requires only basic kitchen equipment and patience. It's ideal for anyone with one or two hives.

Setting Up Your Straining System

The most common setup is a two-stage filter over a bucket.

- Start with a clean, food-grade bucket.

- Place a fine-mesh strainer over the bucket. A purpose-made nylon honey filter or even a new paint strainer bag (200-400 micron) works perfectly.

- Place a coarser strainer, like a standard kitchen colander, inside or on top of the finer mesh. This first stage will catch the large pieces of beeswax.

Preparing and Draining the Comb

Once your setup is ready, you can process the comb.

Place your frames of honeycomb over a large pan or tub. Use a simple serrated bread knife or a dedicated uncapping tool to cut the comb from the frames.

Transfer the chunks of comb into the colander. Use a large spoon or potato masher to gently crush the comb and ensure all cells are broken open. Then, simply walk away. Gravity and warmth will handle the rest.

Patience is Key

This passive method can take anywhere from a few hours to overnight, depending on the temperature of the room and the viscosity of your honey. Let the setup sit, covered with a lid or cloth to keep out dust, until the dripping stops.

Understanding the Trade-offs

The "easiest" method is not always the fastest or the most efficient. Understanding the compromises is key to managing your expectations.

Speed vs. Simplicity

A gravity-fed system is simple but slow. Centrifugal extractors—machines that spin frames to sling honey out—are much faster and keep the combs intact for reuse. However, they represent a significant investment in cost, space, and cleanup effort. For the hobbyist, gravity is often the most practical choice.

Clarity vs. Filtration Level

The clarity of your final product depends on the fineness of your filter.

A very fine filter (e.g., 200 microns) produces crystal-clear honey but can clog more easily. A coarser filter is faster and less prone to clogging but may allow some very fine wax particles or pollen to remain. This is often preferred by those who want a more "raw and unfiltered" product.

Preserving Raw Qualities

This minimal processing method is ideal for producing raw honey. By avoiding high heat, you preserve the delicate enzymes, aromas, and beneficial compounds that can be damaged by commercial processing techniques. The key is gentle warmth, not active heating.

Making the Right Choice for Your Goal

Your ideal straining method depends on what you value most in the final product.

- If your primary focus is maximum simplicity: Use a single, coarse kitchen colander over a bucket. The honey will be clean enough for personal use but may contain fine wax particles.

- If your primary focus is crystal-clear honey: Use a two-stage system with a coarse colander to catch large wax chunks and a finer nylon filter (200-400 microns) as the second stage.

- If your primary focus is preserving raw qualities: Ensure the entire process is done at a stable room temperature and avoid any direct heating to protect the honey's natural enzymes and delicate aromas.

By understanding these basic principles, you can strain your honey harvest efficiently and effectively with minimal equipment.

Summary Table:

| Key Factor | Why It Matters | Simple Solution |

|---|---|---|

| Gravity | Honey is denser than wax and will naturally flow down. | Use a colander or strainer over a bucket. |

| Temperature | Warmth (75-90°F) makes honey less viscous and flow faster. | Strain in a warm room; avoid direct heat. |

| Surface Area | More exposed cells mean faster, more complete draining. | Cut or crush comb; avoid squeezing. |

| Filtration | Filter fineness determines clarity vs. speed. | Use a two-stage system: coarse strainer followed by a fine mesh bag (200-400 micron). |

Ready to Scale Up Your Honey Harvest?

This guide covers the simplest method for hobbyists. If you're a commercial apiary or beekeeping equipment distributor looking to improve efficiency and yield, HONESTBEE has the professional solutions for you.

We supply durable, high-volume equipment designed for commercial operations, including:

- Commercial-grade honey strainers and filters

- Uncapping tanks and settling tanks

- Complete honey processing systems

Let us help you streamline your operation. Contact our wholesale experts today to discuss your needs and get bulk pricing on reliable beekeeping supplies.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- 10L Stainless Steel Electric Honey Press Machine

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What is the overall importance of using the right equipment in honey filtering? Boost Quality & Marketability

- What methods are used for straining honey? Choose the Right Method for Your Scale

- Why is filtering important in honey processing, and what equipment is used? A Guide to Quality & Efficiency

- How does a double sieve honey strainer work? Achieve Crystal Clear Honey with Professional Two-Stage Filtration

- How does honey filtering and storage equipment affect market value? Maximize Profits with Single-Origin Quality