To clean a honey press after use, the process involves two primary phases. First, you must remove the bulk of the remaining pressed wax, which is best accomplished by disassembling the press cage and using boiling water to melt and scrape away the stubborn wax. Second, all components that touched honey must be thoroughly washed with warm water and a food-safe detergent, followed by a complete rinse and drying before reassembly.

Cleaning a honey press is not a single action but a sequential process. You must first address the physical problem of hardened wax before tackling the hygienic problem of sticky honey residue to ensure both the longevity of your equipment and the purity of your next harvest.

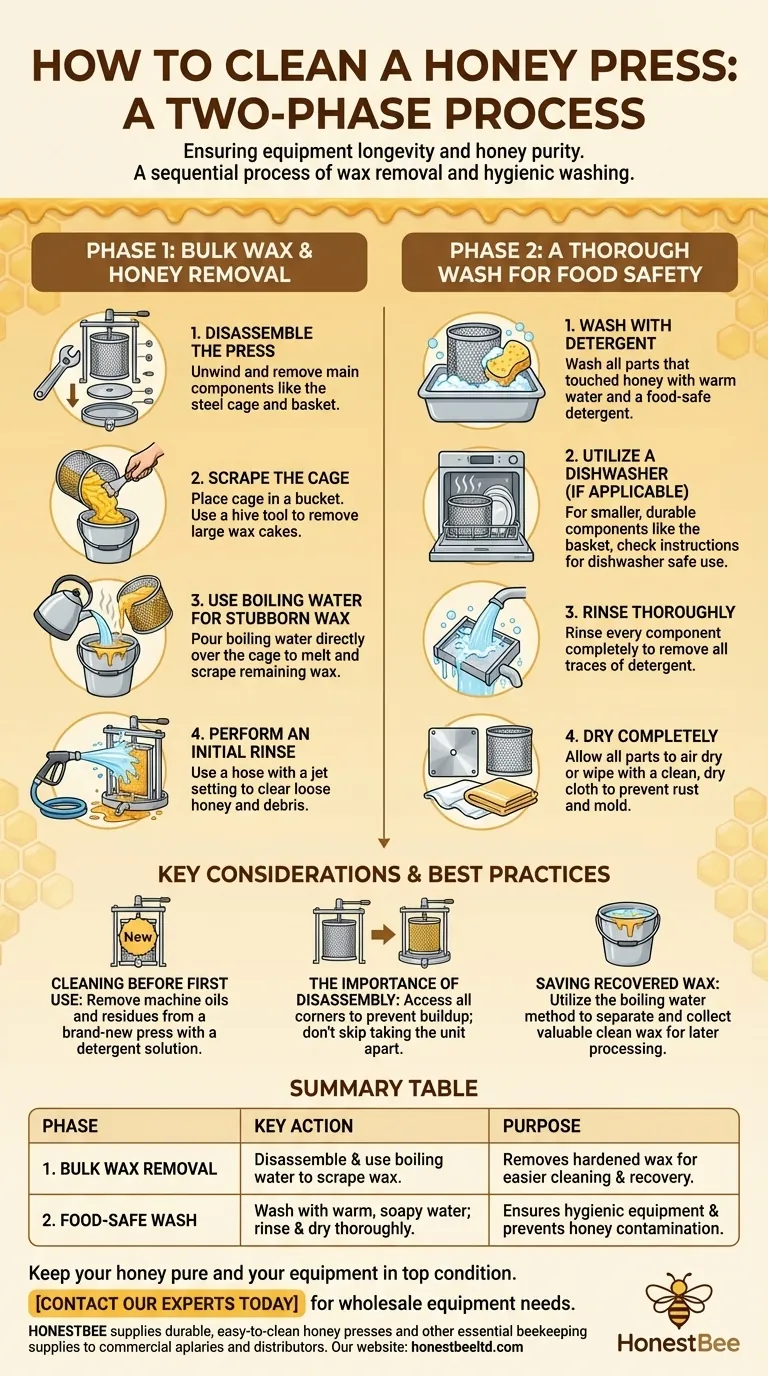

The Two-Phase Cleaning Process

Properly cleaning a honey press requires you to handle two very different substances: solid wax and sticky honey. An effective method tackles each in turn.

Phase 1: Removing Bulk Wax and Honey

This initial step focuses on removing the physical debris left after pressing.

- Disassemble the Press: Unwind the press and remove the main components, particularly the steel cage or basket containing the compressed wax cappings.

- Scrape the Cage: Place the cage in a suitable bucket or container. Use a hive tool or scraper to remove the large, compressed cake of wax.

- Use Boiling Water for Stubborn Wax: Pour boiling water directly over the cage. The intense heat will instantly melt the remaining wax that is stuck in the mesh or perforations, making it easy to scrape off.

- Perform an Initial Rinse: For loose honey and debris on the frame and base, a powerful initial rinse with a hose (using a jet setting, if possible) can effectively clear away the majority of the residue before washing.

Phase 2: A Thorough Wash for Food Safety

Once the bulk wax is gone, the goal shifts to removing all traces of honey to prevent stickiness, mold, and contamination.

- Wash with Detergent: Use warm water and a mild, food-safe detergent to wash all parts of the press that came into contact with honey. This includes the cage, the press plate, the collection tray, and the spout.

- Utilize a Dishwasher (If Applicable): For smaller, durable components like a stainless steel mesh basket, running them through a dishwasher can provide an excellent final clean. Always check your manufacturer's instructions first.

- Rinse Thoroughly: This is a critical step. Rinse every component with clean water until all traces of detergent are gone. Any soap residue can taint the flavor of your next honey batch.

- Dry Completely: Allow all parts to air dry completely or wipe them down with a clean, dry cloth. Storing the press while damp can lead to rust on metal parts or mold growth.

Key Considerations and Best Practices

Going beyond the basic steps will ensure your equipment remains in top condition and your honey stays pure.

Cleaning Before First Use

A brand-new press should be cleaned thoroughly before its first use. Manufacturing processes can leave behind machine oils, metal dust, or welding residues that must be removed with a detergent solution to ensure your honey is not contaminated.

The Importance of Disassembly

Honey presses are designed to be easily taken apart for a reason. Taking the time to disassemble the unit allows you to access every corner and surface where honey and wax can hide. Skipping this step can lead to a buildup of old residue that spoils future harvests.

Saving the Recovered Wax

The wax you scrape off is a valuable byproduct. The method of pouring boiling water over the cage in a bucket also helps in recovery. After scraping, you can add cold water to the bucket; the melted wax will float to the top and solidify into a clean cake that can be easily removed for later processing.

Making the Right Choice for Your Goal

Your cleaning regimen can be adapted based on your priorities.

- If your primary focus is speed and efficiency: An initial high-pressure hose rinse, followed by a targeted wash of the basket and spout with warm, soapy water, is a practical and fast approach for routine cleaning.

- If your primary focus is maximizing wax recovery: Carefully follow the boiling water and scraping method in a dedicated bucket to separate and preserve the clean wax before proceeding to the final wash.

- If your primary focus is absolute food safety: Always disassemble the press completely, wash every component with a food-safe detergent, and consider using a natural, food-safe disinfectant on the frame after washing.

A clean press not only ensures the purity of your honey but also protects your equipment for years of reliable service.

Summary Table:

| Phase | Key Action | Purpose |

|---|---|---|

| 1. Bulk Wax Removal | Disassemble and use boiling water to scrape wax. | Removes hardened wax for easier cleaning and recovery. |

| 2. Food-Safe Wash | Wash with warm, soapy water; rinse and dry thoroughly. | Ensures hygienic equipment and prevents honey contamination. |

Keep your honey pure and your equipment in top condition. A properly cleaned press is vital for commercial beekeeping success. HONESTBEE supplies durable, easy-to-clean honey presses and other essential beekeeping supplies to commercial apiaries and distributors. Contact our experts today to discuss your wholesale equipment needs and ensure the quality of every harvest.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Professional Thermostatic Conical Honey Melter

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

People Also Ask

- What auxiliary consumables were used in historical honey pressing? The Role of Esparto Mats in Traditional Extraction

- What are the steps for extracting honey using a press? Master Traditional Extraction for Pure, Flavorful Honey

- What types of combs are best suited for the honey press? Salvage Honey from Old or Damaged Combs

- What role does a high-pressure hydraulic press play in processing merva? Boost Your Wax Recovery Yield Today

- How does the use of an industrial-grade honey press improve the hygiene quality of honey products? Elevate Safety

- What are the limitations of the 'crush & strain' honey harvesting method? Overcoming Cold Weather Viscosity Challenges

- What are the characteristics of using an industrial-grade press for honey extraction? Maximize Nutritional Density

- What makes the Honey Press a valuable tool for honey enthusiasts and beekeepers? Unlock Superior Honey Quality and Yield