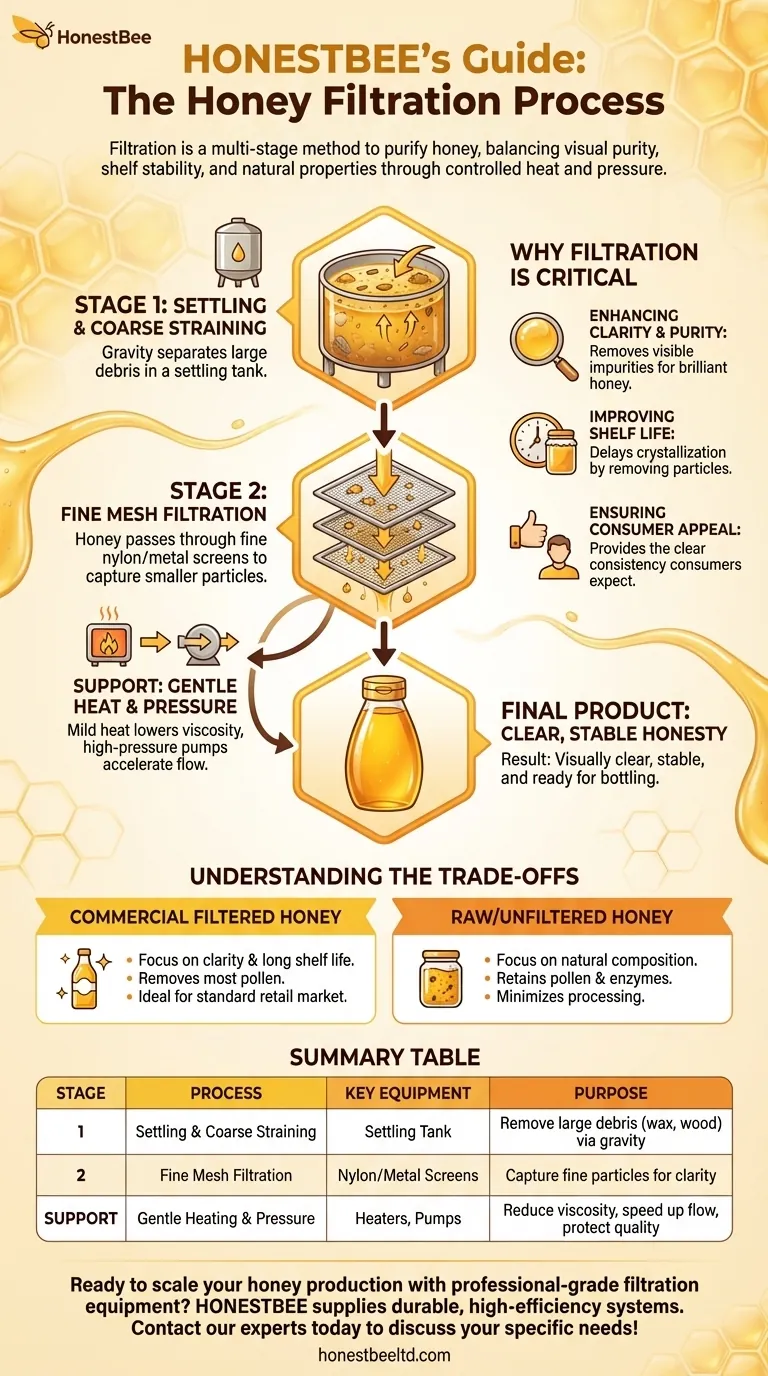

Filtration in honey processing is a multi-stage method designed to purify the final product. The process begins with a settling period to remove large debris like wax, followed by passing the honey through fine mesh screens to capture smaller particles, ensuring a clear and stable product ready for bottling.

The core purpose of honey filtration is not just to clean the honey, but to achieve a specific balance between visual purity, shelf stability, and the preservation of its natural properties. The methods used, particularly the application of heat and pressure, determine the final character of the honey.

Why Filtration is a Critical Step

Filtration is a standard, non-negotiable step in large-scale honey production for several key reasons that go beyond simple aesthetics. It directly impacts the product's quality, stability, and marketability.

Enhancing Clarity and Purity

The most obvious goal of filtration is to remove visible impurities. This includes particles of beeswax, wood from the hive frames, and other small debris collected during the extraction process.

The result is a visually clear, brilliant honey that consumers associate with high quality and purity.

Improving Shelf Life

Fine particles, especially pollen and tiny wax crystals, can act as nucleation points, accelerating the natural process of crystallization.

By removing these particles, filtration helps keep the honey in a liquid state for a longer period, extending its shelf life on the retail shelf and in the consumer's pantry.

Ensuring Consumer Appeal

A clear, smooth honey without specks or cloudiness is what most consumers expect. Filtration ensures this consistency and makes the product more attractive, which can directly influence purchasing decisions and brand reputation.

The Step-by-Step Filtration Process

Commercial honey filtration is a carefully controlled workflow that balances efficiency with the need to protect the honey's delicate nature. It typically involves several distinct stages.

Stage 1: Settling and Coarse Straining

Before fine filtering, raw honey is often held in a settling tank. Here, gravity does the initial work.

Lighter particles like bits of wax and large debris naturally rise to the surface, where they can be skimmed off. This reduces the load on the finer filters in the next stage.

Stage 2: Fine Mesh Filtration

After settling, the honey is passed through a series of fine mesh filters, typically made of nylon or metal.

These screens are designed to capture smaller suspended particles that did not separate during settling, resulting in a much cleaner and clearer liquid.

The Role of Gentle Heat

Honey is highly viscous, meaning it's thick and flows slowly. To aid the filtration process, processors often apply mild, gentle heat.

This temporarily lowers the honey's viscosity, allowing it to pass through the fine filters more easily and efficiently without damaging its natural enzymes or flavor.

The Use of Pressure Systems

In many large-scale operations, high-pressure pumps are used to push the honey through the filtration system.

This significantly accelerates the process, allowing for higher volumes to be processed quickly while enhancing the degree of purification.

Understanding the Trade-offs

While filtration is essential for the commercial honey market, it's important to understand the compromises involved. The level of filtration directly impacts the final product's composition.

The Debate Over Pollen

Standard fine filtration removes most, if not all, of the pollen naturally present in honey. While this improves clarity and delays crystallization, it also removes a key component.

Some consumers specifically seek out unfiltered or raw honey because they value the presence of local pollen and the enzymes that are more abundant in less-processed products.

The Risk of Overheating

The application of heat is a delicate balance. While gentle warming is beneficial, excessive heat can be destructive.

Overheating can degrade the honey's complex flavor profile, destroy beneficial enzymes, and darken its color, fundamentally altering the natural product. This is why reputable processors carefully control temperatures throughout the workflow.

Making the Right Choice for Your Goal

Understanding the filtration process empowers you to select a honey that aligns with your specific priorities.

- If your primary focus is clarity and a long shelf life: A commercially filtered honey is the ideal choice, as it is processed to remain liquid and pure in appearance.

- If your primary focus is natural composition and enzymes: Look for products labeled "raw" or "unfiltered," which undergo minimal straining to retain pollen and other natural elements.

Ultimately, the filtration method is a key factor that defines the honey's final texture, stability, and nutritional profile.

Summary Table:

| Stage | Process | Key Equipment | Purpose |

|---|---|---|---|

| 1 | Settling & Coarse Straining | Settling Tank | Remove large debris (wax, wood) via gravity |

| 2 | Fine Mesh Filtration | Nylon/Metal Screens | Capture fine particles for clarity |

| Support | Gentle Heating & Pressure | Heaters, Pumps | Reduce viscosity, speed up flow, protect quality |

Ready to scale your honey production with professional-grade filtration equipment?

HONESTBEE supplies durable, high-efficiency beekeeping supplies and equipment—including commercial filtration systems—to commercial apiaries and distributors through our wholesale-focused operations. We help you achieve the perfect balance of purity, shelf stability, and processing speed.

Contact our experts today to discuss your specific needs and get a customized solution!

Visual Guide

Related Products

- Professional Stainless Steel Honey Filter with Support Handle

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Two-Stage Plastic Honey Filter for Buckets

People Also Ask

- How do precision filtration systems contribute to honey quality? Elevate Purity and Market Value in Processing

- What role does high-precision filtering equipment play in post-harvest honey processing? Ensure Purity and Clarity

- How does honey filtering and storage equipment affect market value? Maximize Profits with Single-Origin Quality

- What role does industrial honey filtration play? Enhance Market Value with Professional Processing Equipment

- What role do mechanical harvesting and filtration systems play in honey quality? Optimize Purity & Market Value

- How does a vacuum filtration system with multi-stage filter papers function? Optimize Royal Jelly Purity and Clarity

- What roles do fine filtration and standardized packaging play in the post-processing of stingless bee honey?

- How does honey filtration and homogenization equipment affect the commercial value of Robinia pseudoacacia honey?