At its core, a honey refractometer is a specialized tool used to measure the moisture content in honey. This single measurement is the most critical factor for a beekeeper when determining if honey is ready for extraction and jarring. By providing a precise reading, it helps ensure the quality, stability, and commercial viability of the final product.

The fundamental challenge in honey production is preventing fermentation, which occurs when water content is too high. A honey refractometer solves this by providing a quick and accurate measurement, empowering the beekeeper to harvest only when the honey is stable and ready.

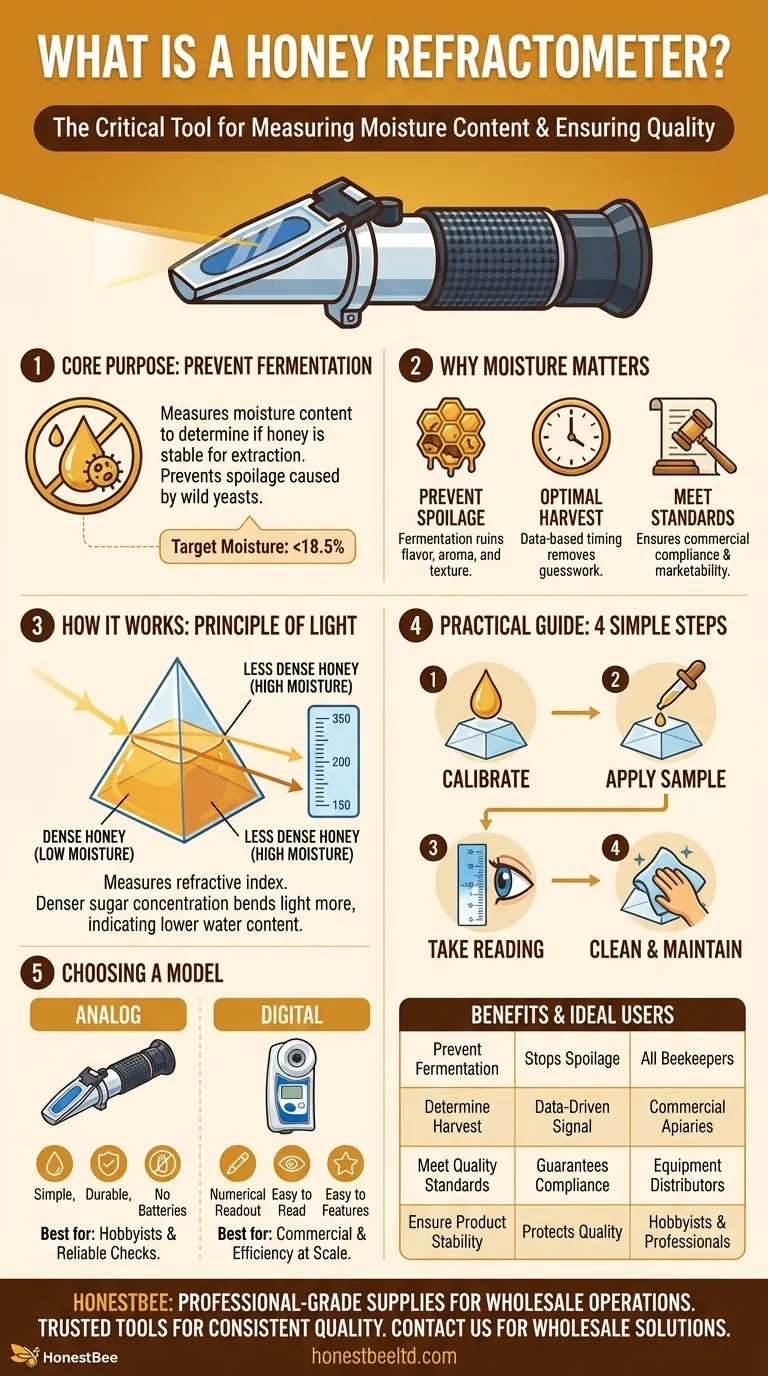

Why Moisture Content is the Critical Factor

The entire process of bees making honey is about reducing the water content of nectar. A refractometer is the tool that confirms when their job is complete and the honey is ready for a long shelf life.

Preventing Fermentation and Spoilage

Honey with a moisture content above approximately 20% is susceptible to fermentation. Wild yeasts present in the honey will begin to feed on the sugars, producing alcohol and carbon dioxide.

This process ruins the honey's flavor, aroma, and texture, often rendering it unusable or downgrading it to lower-quality "baker's honey."

Ensuring Optimal Harvest Timing

A refractometer gives the beekeeper a definitive, data-based answer to the question, "Is the honey ready?" It removes the guesswork from harvesting.

By testing a small sample, you can confirm that the bees have sufficiently dehydrated the honey to a safe moisture level (typically below 18.5%) before you undertake the labor-intensive process of extraction.

Meeting Legal and Commercial Standards

For honey to be sold commercially, it must meet specific quality standards. A key legal requirement in many regions is a moisture content below a certain threshold.

Using a refractometer ensures your product is compliant, protecting both your reputation and your revenue. It provides the quality control necessary for a consistent and marketable product.

How a Refractometer Works: The Principle of Light

The device doesn't measure water directly. Instead, it measures how the properties of the honey affect light and translates that into a moisture reading.

Measuring the Refractive Index

A refractometer works by measuring the refractive index of a liquid. This is simply a measurement of how much a beam of light bends, or refracts, as it passes through the substance.

Linking Solids to Refraction

The refractive index of honey is directly related to its density. Honey with a higher concentration of dissolved solids—primarily sugars—is denser.

This higher density causes light to bend more. Conversely, honey with more water is less dense, and light bends less.

From Refraction to a Moisture Reading

The honey refractometer is calibrated specifically to correlate the angle of light refraction to the percentage of water content.

When you look through the eyepiece, you see a scale. The boundary line between the light and dark areas points directly to the moisture percentage, giving you an immediate and actionable reading.

The Practical Guide to Using a Honey Refractometer

Proper technique is essential for accurate results. Following these simple steps will ensure you get reliable data every time.

Step 1: Calibration is Non-Negotiable

You must calibrate the refractometer before each use to ensure its accuracy. Most models come with a specific calibration fluid or reference solution.

If a reference solution isn't available, pure olive oil can often be used as a substitute, as it should correspond to a known reading (typically 27% on the water scale).

Step 2: Applying the Honey Sample

Place just one or two drops of honey onto the clean, dry prism surface.

Close the daylight plate gently. The honey should spread evenly across the entire surface of the prism without air bubbles or overflowing.

Step 3: Taking the Reading

Hold the refractometer up to a natural light source and look through the eyepiece.

The reading is taken where the boundary line between the blue and white fields (or dark and light areas) crosses the graduated scale. This number is your honey's moisture content percentage.

Step 4: Proper Cleaning and Maintenance

Immediately after taking a reading, clean the prism and daylight plate with a soft, damp cloth. Any leftover honey residue will dry, crystallize, and interfere with your next measurement. Never rinse the device under running water.

Understanding the Trade-offs When Choosing a Model

While all honey refractometers perform the same core function, there are key differences to consider.

Accuracy vs. Price

More expensive, lab-grade models may offer slightly higher precision. For a commercial operation where honey is sold based on strict specifications, this investment can be justified.

For a hobbyist, a standard, reliable analog model is more than sufficient for ensuring honey quality for personal use or small-scale sales.

Analog vs. Digital

Traditional analog refractometers are simple, durable, and require no batteries. They are the most common type used by beekeepers.

Digital refractometers provide a numerical readout, eliminating any ambiguity in reading the scale. Some advanced models may also offer features like temperature compensation or data logging, which can be useful for larger operations.

Making the Right Choice for Your Goal

Select a tool that aligns with the scale and requirements of your beekeeping operation.

- If your primary focus is hobbyist beekeeping: A reliable, basic analog refractometer is the perfect tool to ensure your honey is stable and high-quality.

- If your primary focus is commercial production: Invest in a durable and highly accurate model to guarantee consistent compliance with commercial and legal standards.

- If your primary focus is process efficiency at scale: A digital refractometer can streamline your quality control workflow and reduce the potential for human error in reading the scale.

Ultimately, a honey refractometer transforms a subjective guess into an objective, data-driven decision, safeguarding the integrity of your hard-earned harvest.

Summary Table:

| Purpose | Key Benefit | Ideal For |

|---|---|---|

| Prevent Fermentation | Stops spoilage by ensuring moisture is below 18.5% | All Beekeepers |

| Determine Harvest Timing | Provides a data-driven signal for when honey is ready | Commercial Apiaries |

| Meet Quality Standards | Guarantees honey meets legal and commercial requirements | Equipment Distributors |

| Ensure Product Stability | Protects the flavor, aroma, and shelf life of the final product | Hobbyists & Professionals |

Protect Your Harvest and Your Profits with the Right Equipment

For commercial apiaries and beekeeping equipment distributors, precise quality control is non-negotiable. A reliable honey refractometer is a fundamental tool for safeguarding your product's quality, stability, and market value.

HONESTBEE supplies professional-grade beekeeping supplies and equipment through wholesale-focused operations. We provide the durable, accurate tools that commercial-scale beekeepers trust to meet the highest standards.

Ready to equip your operation with professional tools? Contact our team today to discuss your needs and explore our wholesale solutions.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What is the function of high-precision refractometers and testing kits in honey testing? Ensure Purity & Quality

- What is the primary function of a benchtop refractometer in the analysis of honey quality? Master Moisture Control

- What should be done after taking a reading with a honey refractometer? Protect Your Investment and Ensure Accuracy

- What is the function of a portable honey refractometer? Essential Tool for Moisture and Brix Quality Testing

- What is the application value of portable field testing equipment for stingless honey? Ensure Real-Time Quality Control

- What is the function of a benchtop refractometer in determining the moisture content of Cassava honey? Expert Guide

- How are high-precision electronic scales utilized in honey yield estimation? Master Data-Driven Extraction

- Why is an industrial-grade conductivity meter used in the quality monitoring of honey? Ensure Honey Purity and Origin