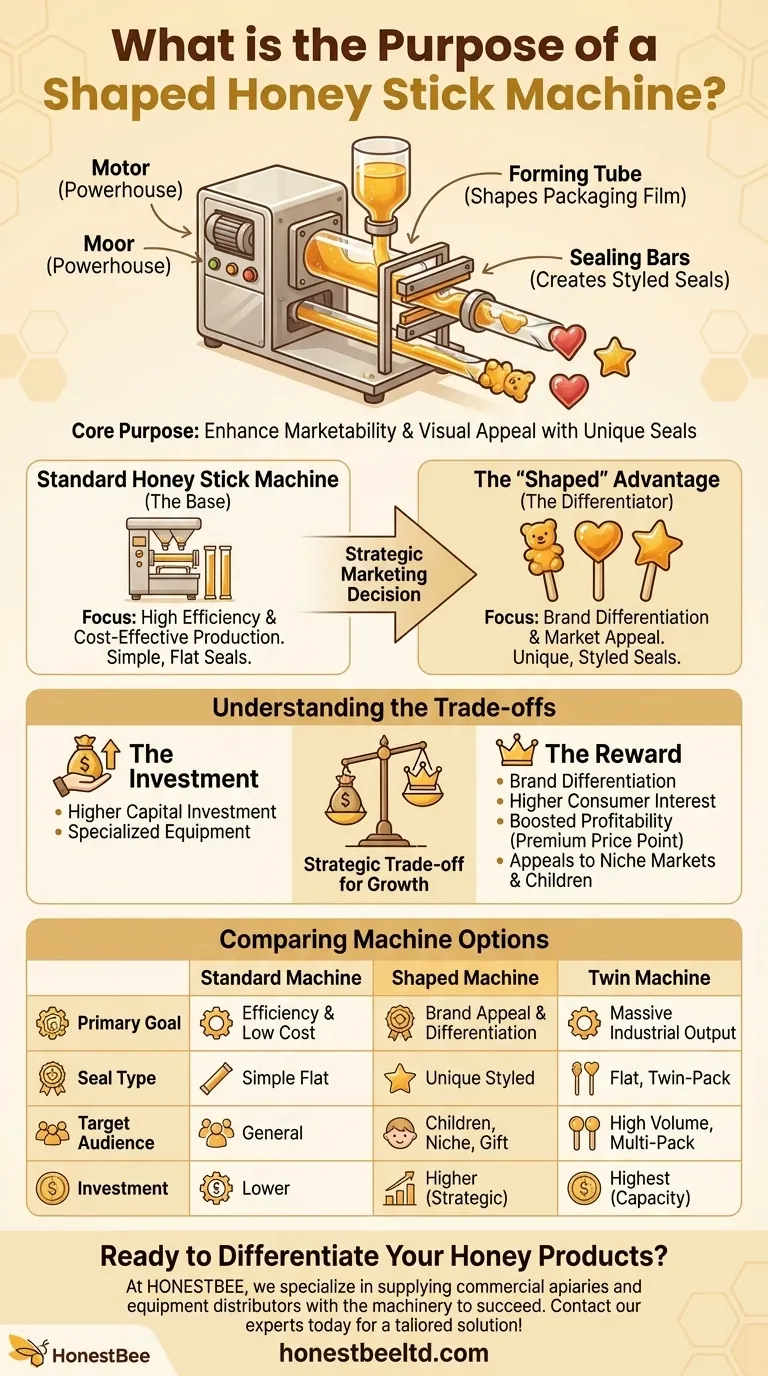

At its core, a shaped honey stick machine is a specialized piece of packaging equipment designed to create honey sticks with unique, styled seals. Its primary purpose is not just to package honey, but to enhance the product's marketability and visual appeal, making it more attractive to consumers, especially children.

The decision to use a shaped honey stick machine is less about production and more about marketing. It represents a strategic trade-off: a higher initial investment for a product that stands out on the shelf and commands greater consumer interest.

How Honey Stick Machines Operate

Before understanding the "shaped" variant, it's essential to grasp the function of a standard honey stick machine.

The Core Function

A honey stick machine automates the process of filling and sealing honey into small, single-serving plastic tubes. These narrow packs are convenient for on-the-go lifestyles and provide precise portion control.

Key Mechanical Components

The machine's motor is its powerhouse, converting electrical energy into the mechanical force needed to run the system. A forming tube takes a flat roll of packaging film and shapes it into the characteristic stick-like tube. Finally, sealing bars close off the ends of the tube to contain the honey.

The Automation Advantage

Modern machines are highly automated, offering immense benefits for producers. They provide high production efficiency, accuracy, and a hygienic design that minimizes contamination, often adhering to cGMP (Current Good Manufacturing Practice) guidelines.

The "Shaped" Advantage: A Focus on Market Appeal

A shaped honey stick machine builds upon the standard foundation with one critical difference.

The Differentiating Factor: Styled Seals

The key distinction is the machine's ability to create unique, stylized seals at the ends of the stick. Instead of a simple flat seal, it can produce shapes that make the product more playful and memorable.

Targeting a Specific Audience

This feature is a powerful marketing tool. The unique shapes are designed to capture attention and are particularly effective at appealing to children, turning a simple honey stick into a novelty item.

Boosting Profitability

By creating a more desirable and differentiated product, a shaped machine can help justify a higher price point. This playful approach can directly translate to increased sales and higher profit margins for the producer.

Understanding the Trade-offs

Choosing this specialized equipment involves a clear cost-benefit analysis.

The Obvious Benefit: Brand Differentiation

In a competitive market, a unique product stands out. The styled seal offers a simple but effective way to differentiate your honey sticks from standard, commodity-like offerings.

The Major Drawback: Higher Investment

This specialization comes at a cost. A shaped honey stick machine requires a higher capital investment compared to standard models that produce a simple, flat-sealed stick.

How It Compares to Other Machines

The shaped machine occupies a specific niche in the production landscape.

Standard Automatic Machines

These are the workhorses for large-scale production. Often built with multiple lanes, they can output a high volume of standard honey sticks per minute with full automation. Their focus is pure efficiency.

Twin Honey Stick Machines

A twin machine increases output further by using two hoppers to fill two attached stick packs simultaneously. This is ideal for very large packaging lines or for pairing honey with a complementary product in a single package.

Making the Right Choice for Your Business

Your production goal will determine the right equipment for your operation.

- If your primary focus is maximum efficiency at the lowest cost: A standard, multi-lane automatic machine is the most logical choice.

- If your primary focus is brand differentiation and targeting niche markets: The higher investment in a shaped honey stick machine is a strategic marketing decision.

- If your primary focus is massive industrial output: A twin honey stick machine offers the next level of production capacity.

Ultimately, choosing a shaped honey stick machine is an investment in your brand's unique identity.

Summary Table:

| Feature | Standard Machine | Shaped Machine |

|---|---|---|

| Primary Goal | High-volume, cost-effective production | Brand differentiation and market appeal |

| Seal Type | Simple, flat seals | Unique, styled seals (shapes) |

| Target Audience | General consumers | Children, niche markets, gift sectors |

| Investment Level | Lower | Higher (strategic marketing investment) |

Ready to differentiate your honey products and capture new markets?

At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with the machinery to succeed. A shaped honey stick machine is a powerful tool for boosting brand recognition and profitability.

Let us help you make the right investment for your packaging line. Contact our experts today to discuss your production goals and get a tailored solution.

Visual Guide

Related Products

- Honey Stick Filler Vertical Paste Sachet Packing Machine for Honey Sachets

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- Why are industrial honey-filling machines essential? Scale Your Production with Safety and Precision

- How can the expected output of a honey stick machine be determined? Calculate Your True Production Capacity

- What are the features of an automatic honey stick machine? Maximize Your High-Volume Honey Production

- How do industrial-grade filling and packaging machines contribute to the market value of certified honey? Unlock Premium Growth

- What are the advantages of semi-automatic filling machines? Boost Production Speed & Versatility

- What are the advantages of industrial honey filling machinery? Maintain Honey Quality and Chemical Stability

- What is a semi-automatic honey filler? Scale Your Honey Production with Precision and Efficiency

- What maintenance procedures are required for a honey-filling machine? Essential Tips for Longevity and Efficiency