The fundamental purpose of using a double boiler is to melt beeswax safely and gently. By using the steam from simmering water as an indirect heat source, this method gives you precise temperature control, preventing the wax from scorching or, more dangerously, reaching its flashpoint and igniting.

The core problem with melting beeswax isn't just about turning it into a liquid; it's about managing risk. A double boiler is the essential tool for this, using indirect heat to keep the wax temperature safely below its flashpoint and ensuring a high-quality, unburnt final product.

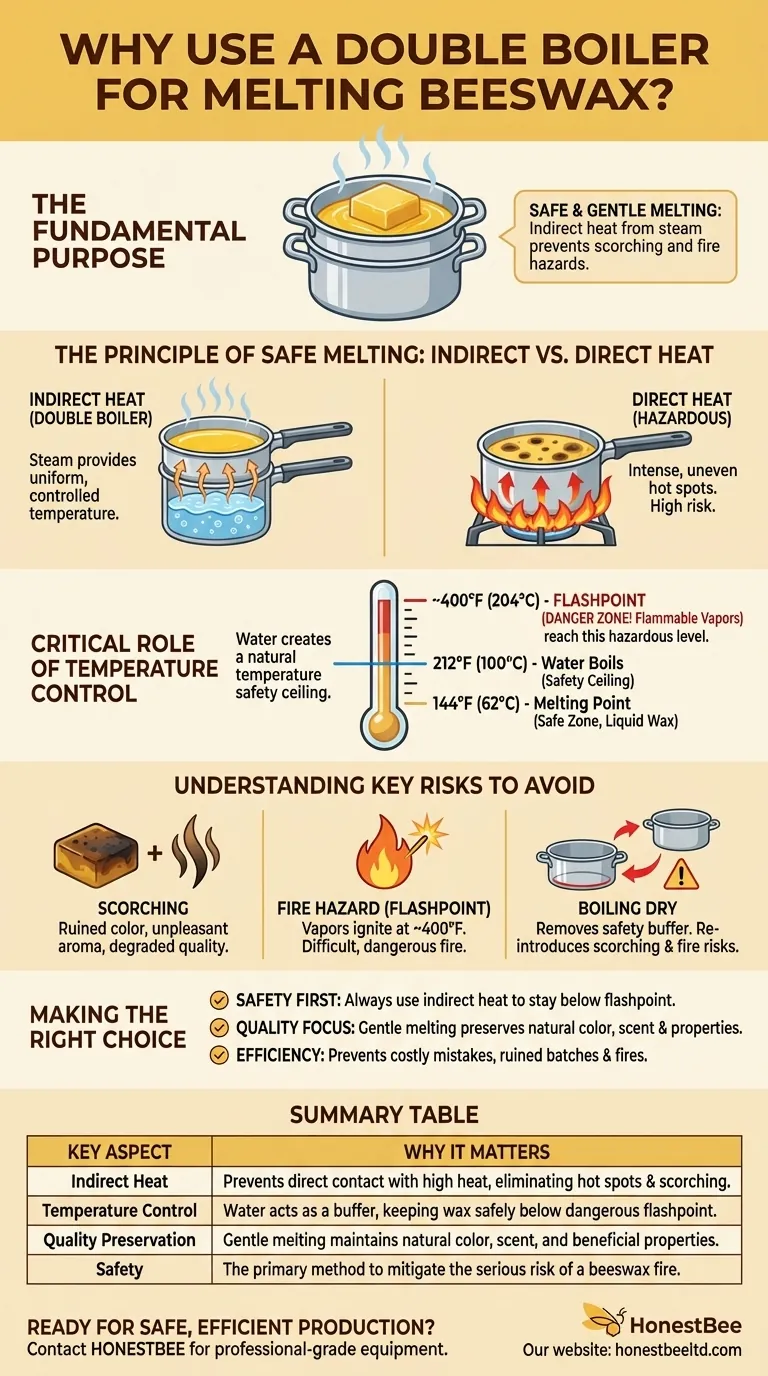

The Principle of Safe Melting: Indirect vs. Direct Heat

To understand why a double boiler is non-negotiable for beeswax, you must first understand the difference between direct and indirect heat and the hazards associated with each.

How a Double Boiler Provides Indirect Heat

A double boiler consists of two stacked pots. The bottom pot holds a small amount of water, and the top pot, resting above it, holds the beeswax.

When you heat the apparatus, the water turns to steam. This steam, trapped between the two pots, transfers its heat gently and evenly to the upper pot, melting the wax without any direct contact with the intense heat of the stovetop.

The Critical Role of Temperature Control

Beeswax has a relatively low melting point, typically around 144°F (62°C). However, its flashpoint—the temperature at which its vapors can ignite with a spark—is much higher but easily reachable with direct heat.

The beauty of a double boiler is that the water in the bottom pot acts as a natural temperature regulator. Water boils at 212°F (100°C), creating a temperature ceiling that makes it nearly impossible for the wax to overheat to a dangerous level.

Why Direct Heat is So Dangerous

Placing a pot of beeswax directly on a burner is extremely hazardous. Electric and gas burners create intense, uneven hot spots that can quickly raise the temperature of the wax far beyond its melting point.

This lack of control can easily lead to scorching the wax, ruining its color and aroma, or worse, causing it to reach its flashpoint and start a fire.

Understanding the Key Risks to Avoid

Using a double boiler is about mitigating specific, serious risks. Failing to understand these hazards can lead to ruined materials or a dangerous situation in your workspace.

The Danger of Scorching

Scorching occurs when the wax is exposed to excessive heat, causing it to burn. This permanently darkens the wax, gives it an unpleasant burnt smell, and can degrade its quality for use in cosmetics or candles. A double boiler's gentle heat prevents this entirely.

The Fire Hazard: The Beeswax Flashpoint

This is the most critical risk to manage. When overheated, beeswax releases flammable vapors. If these vapors reach the flashpoint temperature (typically around 400°F / 204°C), they can ignite from a nearby flame or even a spark. A wax fire is difficult and dangerous to extinguish.

The Critical Mistake of Letting Water Boil Dry

The entire safety system of a double boiler depends on the water in the bottom pot. If you let this water completely boil away, you have effectively removed the safety buffer.

The empty bottom pot will then get extremely hot, transferring direct, uncontrolled heat to the top pot and re-introducing the risks of scorching and fire. Always ensure there is water in the bottom pot.

Making the Right Choice for Your Project

Your goal determines your method, and when working with beeswax, the goals of safety and quality are paramount. The double boiler is the tool that serves both.

- If your primary focus is safety: Always use a double boiler or a makeshift equivalent (a heatproof bowl over a saucepan of water) to keep the wax temperature safely below its flashpoint. Never melt beeswax directly on a heat source.

- If your primary focus is product quality: Use a double boiler for a gentle, even melt that preserves the beeswax's natural color, scent, and beneficial properties without scorching.

- If your primary focus is efficiency: While it may seem slower, using a double boiler prevents costly and time-consuming mistakes like ruining a batch of wax or dealing with a fire, making it the most efficient method in the long run.

Mastering the use of indirect heat is the key to working confidently and safely with beeswax.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Indirect Heat | Prevents direct contact with high heat, eliminating hot spots and scorching. |

| Temperature Control | Water acts as a buffer, keeping wax safely below its dangerous flashpoint (~400°F / 204°C). |

| Quality Preservation | Gentle melting maintains the wax's natural color, scent, and beneficial properties. |

| Safety | The primary method to mitigate the serious risk of a beeswax fire. |

Ready to work with beeswax safely and efficiently?

For commercial apiaries and beekeeping equipment distributors, having the right supplies is the first step to quality production. HONESTBEE provides the professional-grade beekeeping equipment and supplies you need for safe, large-scale operations.

Contact HONESTBEE today to discuss your wholesale needs and ensure your workshop is equipped for success.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What are the negative effects of overheating honey? Preserve Your Honey's Natural Quality

- What equipment is commonly used for heating and processing honey? Essential Tools for Every Beekeeper

- Why is heating honey sometimes necessary? The Essential Guide to Processing & Quality

- How to permanently decrystallize honey? Embrace Its Natural State for Maximum Quality

- Is it safe to heat crystallized honey? Restore Your Honey's Liquid State Safely