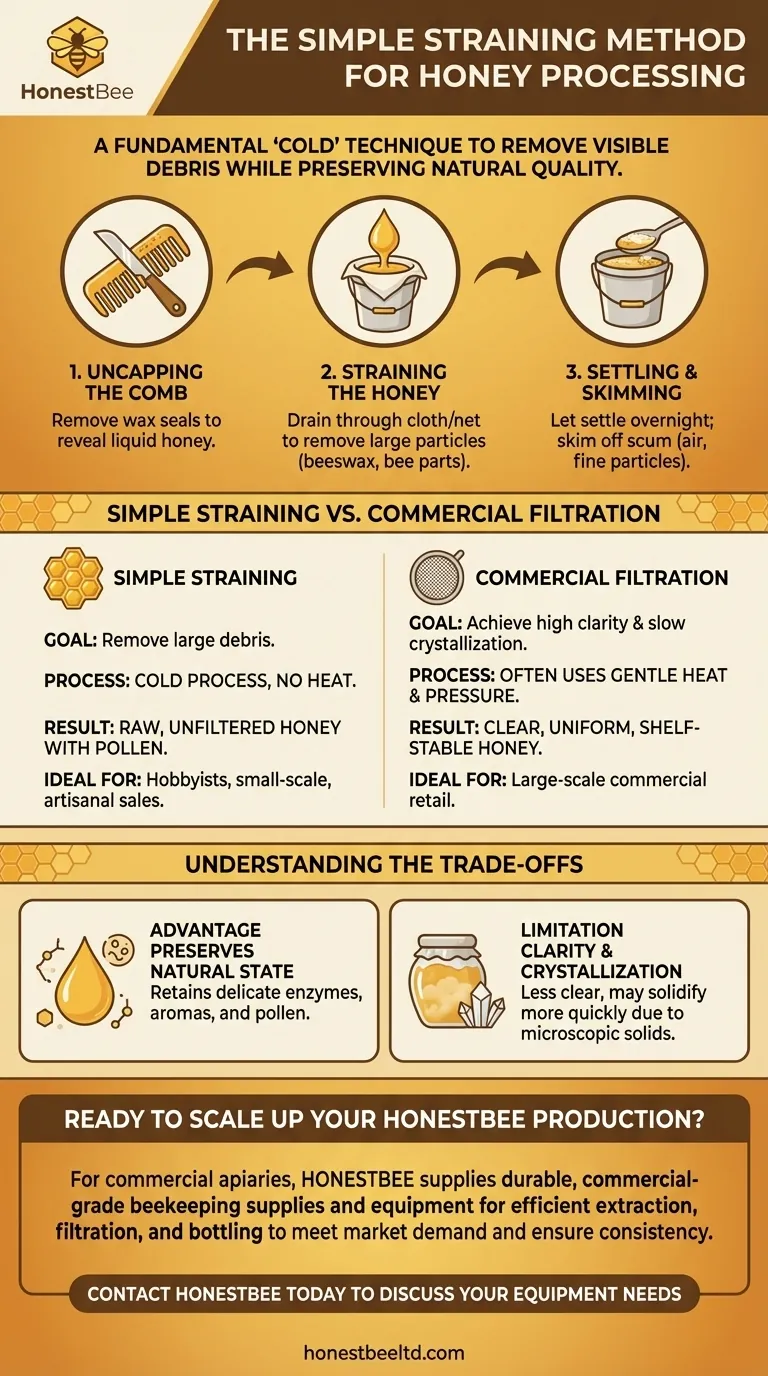

The simple straining method is a fundamental technique used to clean honey after it has been extracted from the comb. It involves uncapping the honeycomb, allowing the honey to drain through a basic cloth or net to remove large impurities like beeswax and other debris, letting it settle, and then skimming any remaining scum from the surface before bottling.

This method is the most straightforward way to process honey, designed to remove visible debris while preserving the honey's natural state. It is distinct from commercial filtration, which aims for a higher level of purity and clarity, often with the use of heat and pressure.

A Step-by-Step Guide to Simple Straining

This method is favored by hobbyists and small-scale beekeepers for its simplicity and minimal equipment requirements. It consists of a few essential steps performed after the honey has been removed from the comb.

Step 1: Uncapping the Comb

Before honey can be strained, the wax cappings that seal each cell must be removed. This is typically done with a special knife or fork, revealing the liquid honey underneath.

Step 2: Straining the Honey

The honey is then allowed to pass through a filter. For this method, a simple straining cloth or a nylon net is tied securely over the mouth of a clean, food-grade container. The references suggest folding the net once to create two layers for more effective straining.

Step 3: Settling and Skimming

After passing through the strainer, the honey is left to sit undisturbed, usually overnight. This settling period allows finer particles and air bubbles to rise to the surface, forming a scum. This layer is then carefully skimmed off, leaving behind cleaner honey.

How Straining Fits into the Honey Processing Workflow

Simple straining is just one part of the journey from hive to jar. Understanding its place in the overall process is key to understanding its purpose and limitations.

Before Straining: Extraction

First, honey must be extracted from the comb. The most common method uses a honey extractor, a machine that spins the frames at high speed. Centrifugal force pulls the honey out of the cells and onto the walls of the extractor, where it pools at the bottom, ready for the next step.

Straining vs. Filtration: A Key Distinction

Straining is a coarse process. Its goal is to remove large, visible foreign materials like pieces of wax, wood from the frame, or bee parts.

Filtration, on the other hand, is a more intensive process used in larger commercial operations. It often involves gently heating the honey to make it less viscous and then forcing it through very fine mesh filters, sometimes under pressure. This removes tiny particles like pollen, dust, and air bubbles, resulting in a perfectly clear product that is slower to crystallize.

Understanding the Trade-offs of Simple Straining

Choosing this method comes with clear advantages and specific limitations that you must consider.

The Primary Advantage: Preserving a Natural State

The biggest benefit of simple straining is that it is a "cold" process done without heat. This preserves all the delicate enzymes, aromas, and beneficial properties of raw honey. The honey retains its natural pollen content, which many consumers value.

The Key Limitation: Clarity and Crystallization

Because straining only removes large particles, the resulting honey will not be as crystal-clear as commercially filtered honey. It will also contain pollen and other microscopic solids, which can act as seeds for crystallization, meaning it may solidify more quickly.

The Result: A "Raw" and Minimally Processed Product

Honey produced via simple straining is often what is marketed as "raw" or "unfiltered." It is less uniform but is considered by many to be a more natural and wholesome product.

Making the Right Choice for Your Goal

Your processing method should align directly with your desired final product.

- If your primary focus is raw, artisanal honey for personal use or local sale: The simple straining method is ideal, as it cleans the honey while preserving its natural character and beneficial compounds.

- If your primary focus is a highly clear, shelf-stable product for broad commercial retail: You will need to go beyond simple straining and implement a filtration system that likely involves gentle heat and finer filters to achieve uniformity and slow crystallization.

Ultimately, understanding the difference between simple straining and advanced filtration empowers you to produce honey that precisely matches your standards and goals.

Summary Table:

| Aspect | Simple Straining | Commercial Filtration |

|---|---|---|

| Goal | Remove large debris (wax, bee parts) | Achieve high clarity & slow crystallization |

| Process | Cold process, no heat | Often uses gentle heat & pressure |

| Result | Raw, unfiltered honey with pollen | Clear, uniform, shelf-stable honey |

| Ideal For | Hobbyists, small-scale, raw honey sales | Large-scale commercial retail |

Ready to scale up your honey production?

For commercial apiaries and beekeeping equipment distributors, the right tools make all the difference. While simple straining is perfect for small batches, professional operations require efficient, high-volume equipment for extraction, filtration, and bottling.

HONESTBEE supplies the durable, commercial-grade beekeeping supplies and equipment you need to meet market demand and ensure product consistency. We support your growth with wholesale-focused operations.

Contact HONESTBEE today to discuss your equipment needs and streamline your honey processing workflow!

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Stainless Steel Honey Filter with Support Handle

- Two-Stage Plastic Honey Filter for Buckets

People Also Ask

- What filter size for honey? A Beekeeper's Guide to Straining for Clarity and Quality

- What are the benefits of drying honey filtering equipment after use? Protect Your Honey Quality & Equipment Investment

- What is the primary purpose of honey filters? Achieve Professional Clarity & Pure Honey Quality

- What is the role of filtration in honey processing? Ensure Purity, Clarity, and Shelf Life

- What are the functions and advantages of using honey strainers? Ensure Purity & Quality in Your Harvest