A juice filling machine's primary use is to automate the process of dispensing a precise, consistent volume of juice into bottles and other containers. It is a foundational piece of equipment in the food and beverage industry, replacing manual labor to increase speed, ensure product consistency, and maintain hygienic standards for commercial production.

The core purpose of a juice filling machine is not just to put liquid in a bottle. It is engineered to solve the critical business challenges of production speed, product consistency, and operational hygiene, turning a manual craft into a scalable, professional operation.

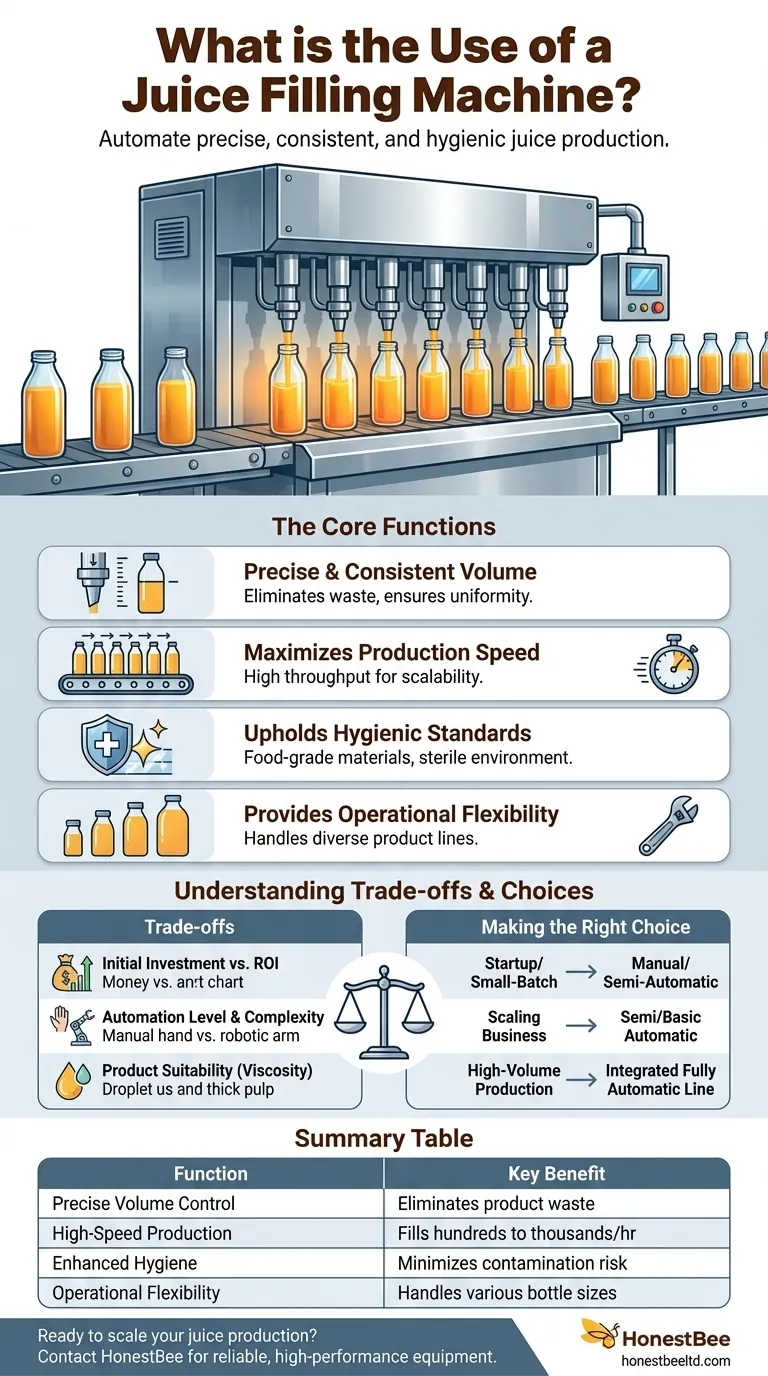

The Core Functions of a Juice Filling Machine

To understand the value of a juice filling machine, we must look beyond the simple act of filling and examine the specific problems it solves for a business. Each function is critical for moving from small-batch production to a commercially viable scale.

Ensuring Precise and Consistent Volume

Manually filling bottles inevitably leads to variation. A filling machine uses precisely calibrated nozzles and controls to dispense the exact same amount of product into every single container.

This precision eliminates product waste from overfilling and prevents customer complaints from underfilling, protecting both your profit margins and brand reputation.

Maximizing Production Speed

The most significant bottleneck in any beverage production is the filling and capping process. An automated system using a conveyor belt can fill hundreds or thousands of bottles per hour.

This dramatic increase in throughput is impossible to achieve with manual labor, making it essential for any business looking to scale and meet market demand.

Upholding Hygienic Standards

Juice is a food product subject to strict safety regulations. Filling machines are constructed with food-grade materials, such as stainless steel, to prevent contamination.

By minimizing direct human contact with the product, these machines create a more sterile environment, reducing the risk of spoilage and ensuring the final product is safe for consumption.

Providing Operational Flexibility

Modern fillers are not single-purpose devices. They are designed with adjustable settings to handle various bottle sizes and shapes.

This allows a producer to use the same machine for a diverse product line—from small 250ml bottles to larger 1-liter containers—without needing separate equipment for each.

Understanding the Trade-offs

While the benefits are clear, selecting a juice filling machine requires a clear-eyed assessment of the costs and complexities involved. It is an investment that must align with your operational scale and business goals.

Initial Investment vs. Long-Term ROI

The primary barrier to entry is cost, with fully automatic systems representing a significant capital expenditure.

However, this initial cost is offset over time by reduced labor expenses, minimized product waste, and the ability to produce at a scale that generates higher revenue.

Automation Level and Complexity

These machines exist on a spectrum from manual to fully automatic. A simple manual filler has a low cost and is easy to operate but offers minimal speed benefits.

A fully automatic line provides maximum speed but requires skilled operators for setup, calibration, and routine maintenance to prevent costly downtime.

Product Suitability

Not all fillers are created equal. A machine optimized for thin, watery juice might perform poorly with thick juices containing significant pulp or smoothies.

The viscosity of your product is a critical factor. The filling mechanism (e.g., gravity, piston, pump) must be matched to the liquid's characteristics to ensure accuracy and prevent blockages.

Making the Right Choice for Your Goal

Your production goals should be the deciding factor in what type of filling machine you choose.

- If your primary focus is a startup or small-batch operation: A manual or semi-automatic machine provides the necessary consistency and hygiene at the lowest initial cost.

- If your primary focus is scaling an existing business: A semi-automatic or a basic fully automatic machine is crucial to meet growing demand and reduce per-unit labor costs.

- If your primary focus is high-volume, large-scale production: An integrated, fully automatic filling line is the only solution to achieve maximum speed, efficiency, and consistency.

Choosing the right filling technology is a foundational step in transforming your juice production from a passion into a professional enterprise.

Summary Table:

| Function | Key Benefit |

|---|---|

| Precise Volume Control | Eliminates product waste and ensures consistent fill levels. |

| High-Speed Production | Fills hundreds to thousands of bottles per hour, enabling scale. |

| Enhanced Hygiene | Uses food-grade materials to minimize contamination risk. |

| Operational Flexibility | Adjustable settings handle various bottle sizes and shapes. |

Ready to scale your juice production with reliable, high-performance equipment?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, efficient machinery needed for large-scale operations. Whether you're a major producer or a distributor building your product line, our wholesale-focused solutions are engineered for reliability and high throughput.

Contact our team today to discuss your production needs and discover how our filling machines can drive your business growth.

Visual Guide

Related Products

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automated Rotary Bottle Unscrambler for Honey Production Line

- Fully Automatic High Speed Centrifugal Bottle Unscrambler

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

People Also Ask

- What is the primary function of a honey stick machine? Automate Your Packaging for Maximum Efficiency

- Why must honey-filling machines be designed to accommodate high osmotic pressure? Engineering for Precision & Quality

- Why is high-performance honey filling and packaging equipment essential? Boost Efficiency & Brand Value

- What is the role of the pump in the honey filling process? Optimize Your Production Speed and Honey Integrity

- What role does the nozzle design play in honey filling machines? Maximize Accuracy & Minimize Waste

- What is the significance of high-efficiency honey-filling machines? Boost Your Brand and Quality Control

- What are the advantages of using a honey stick machine? Boost Efficiency & Expand Your Confectionery Line

- Why is the use of industrial automatic honey filling machines necessary? Secure Premium Forest Honey Quality