The durability of a wax foundation sheet stems from a combination of its core material, structural design, and the way it integrates with the colony's natural behavior. It is engineered to resist the constant wear from bee activity, withstand environmental shifts within the hive, and maintain its integrity over multiple seasons.

At its core, wax foundation durability is not just about the material itself. It's about a synergistic system where the natural resilience of beeswax, the geometric strength of the hexagonal pattern, and the bees' own construction work together to create a lasting and productive comb.

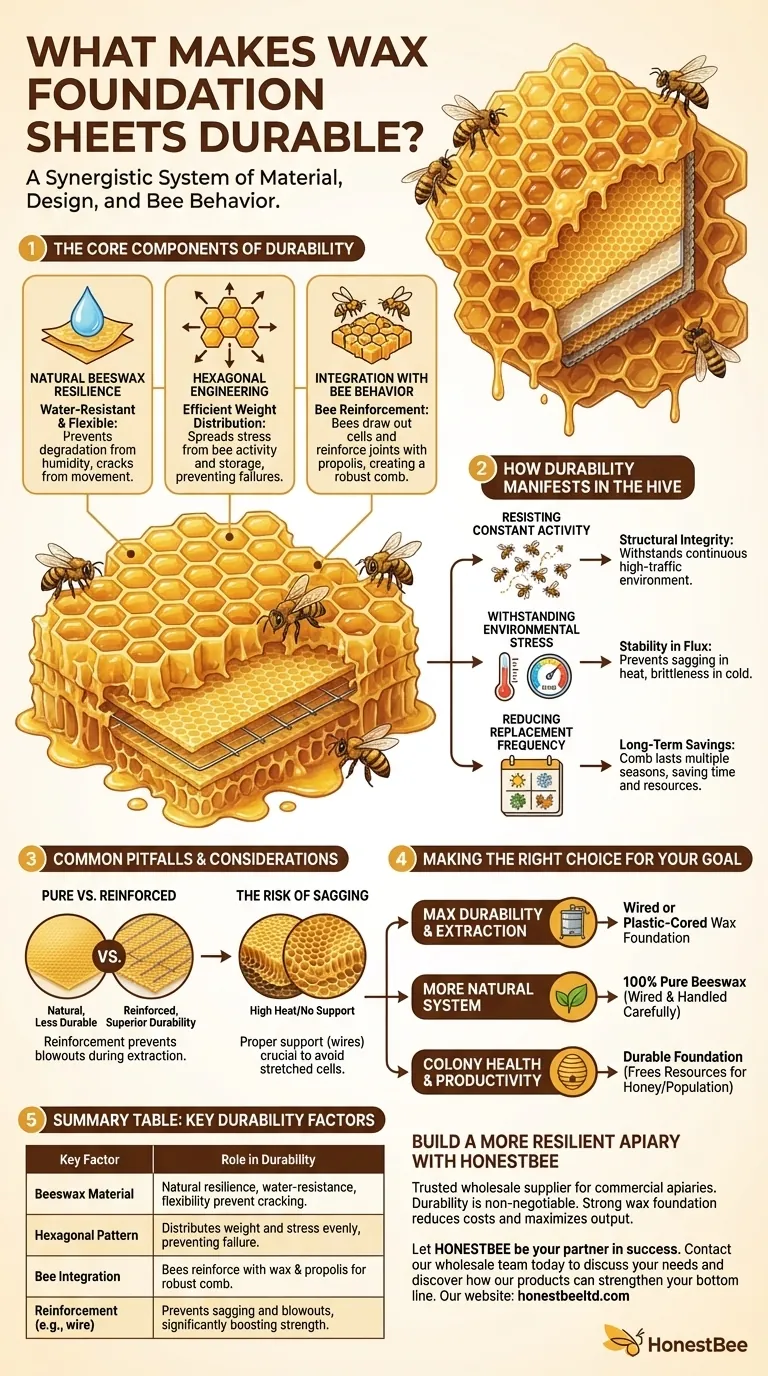

The Core Components of Durability

To understand why wax foundation holds up, we need to look at its fundamental characteristics. Each element plays a distinct role in its overall strength and longevity.

The Natural Resilience of Beeswax

Beeswax is a remarkable natural polymer. It is inherently water-resistant, which prevents it from degrading due to the high humidity inside a beehive.

This material also has a degree of flexibility, allowing it to handle vibrations and minor impacts without cracking, which is essential given the constant movement within a colony.

The Engineering of the Hexagon

The imprinted hexagonal cell pattern is not just a guide for the bees. The hexagon is one of the strongest and most efficient shapes in nature for distributing weight and stress.

This geometric design ensures that the forces exerted by the bees—walking, storing honey, and raising brood—are spread evenly across the entire sheet, preventing localized failures.

The Integration with Bee Behavior

A foundation sheet is a starter template. The bees complete the structure by drawing out the cells with their own wax and reinforcing joints with propolis.

This process transforms the thin foundation into a thick, robust comb that is significantly stronger than the original sheet. The foundation's familiar scent also encourages rapid acceptance and building, which is key to colony health.

How Durability Manifests in the Hive

The theoretical strength of a foundation sheet is only valuable if it translates to real-world performance. Its design directly addresses the primary challenges it will face inside the hive.

Resisting Constant Bee Activity

A colony can have tens of thousands of bees constantly moving across the comb surfaces. The foundation's structural integrity ensures it doesn't break down under this continuous, high-traffic environment.

Withstanding Environmental Stress

The foundation must endure the temperature and humidity fluctuations inside the hive. Its stability prevents sagging in the summer heat and brittleness in the cold, which is crucial for the colony's survival.

Reducing Replacement Frequency

Because a well-built comb on a durable foundation can last for multiple seasons, beekeepers save time and resources. This longevity allows the colony to focus its energy on foraging and reproduction rather than constantly rebuilding comb.

Common Pitfalls and Considerations

While durable, wax foundation is not indestructible. Understanding its limitations is key to using it effectively and avoiding common problems.

Pure Wax vs. Reinforced

Many foundation sheets are reinforced with embedded vertical wires or a plastic core coated in beeswax. While pure wax is more natural, reinforced sheets offer far superior durability.

Reinforcement is especially critical for preventing "blowouts," where the comb disintegrates under the centrifugal force of a honey extractor.

The Risk of Sagging

In very high heat and without proper support (like frame wires), even the best wax foundation can sag under the weight of honey. This can result in stretched cells, which the bees will often use to raise drones, impacting the colony's balance.

Making the Right Choice for Your Goal

Selecting the right foundation depends entirely on your beekeeping philosophy and operational needs.

- If your primary focus is maximum durability and extraction efficiency: Choose a wired or plastic-cored wax foundation for superior strength and sag resistance.

- If your primary focus is a more natural system: Use 100% pure beeswax foundation, but ensure it is properly wired into the frame for support and be prepared to handle it more carefully.

- If your primary focus is colony health and productivity: A durable foundation reduces the need for bees to constantly build new comb, freeing up their resources for honey production and population growth.

Ultimately, choosing the right foundation is a foundational step in building a resilient and productive hive.

Summary Table:

| Key Factor | Role in Durability |

|---|---|

| Beeswax Material | Natural resilience, water-resistance, and flexibility prevent cracking and degradation. |

| Hexagonal Pattern | Distributes weight and stress evenly across the sheet, preventing structural failure. |

| Bee Integration | Bees reinforce the foundation with their own wax and propolis, creating a robust comb. |

| Reinforcement (e.g., wire) | Prevents sagging and "blowouts" during honey extraction, significantly boosting strength. |

Build a more resilient and productive apiary with HONESTBEE.

As a trusted wholesale supplier for commercial apiaries and beekeeping equipment distributors, we understand that durability is non-negotiable. A strong wax foundation is the bedrock of a healthy hive, reducing replacement costs and maximizing your colony's output.

Let HONESTBEE be your partner in success. We supply high-quality, durable beekeeping supplies and equipment designed for the demands of large-scale operations.

Contact our wholesale team today to discuss your needs and discover how our products can strengthen your bottom line.

Visual Guide

Related Products

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Food Grade Plastic bee Foundation for Bee Frames

People Also Ask

- How do bees respond to wax or wire foundations vs. plastic? Achieve Faster Comb Building

- What are the health and practical advantages of foundationless beekeeping? Boost Hive Health & Reduce Costs Today

- What is foundation in beekeeping? Essential Guide to Hive Management and Comb Construction

- What are the quality standards for beeswax foundations? Ensure 100% Pure Wax for a Healthy Hive

- What is the purpose of wax foundation? Boost Hive Efficiency & Honey Production

- How does drone comb foundation function as a biological control tool for Varroa destructor mites? IPM Strategy Guide

- Why is the precise control of cell orientation essential during the production of wax comb foundation?

- What is the significance of using high-quality artificial foundation? Optimize Hive Growth & Ecological Balance