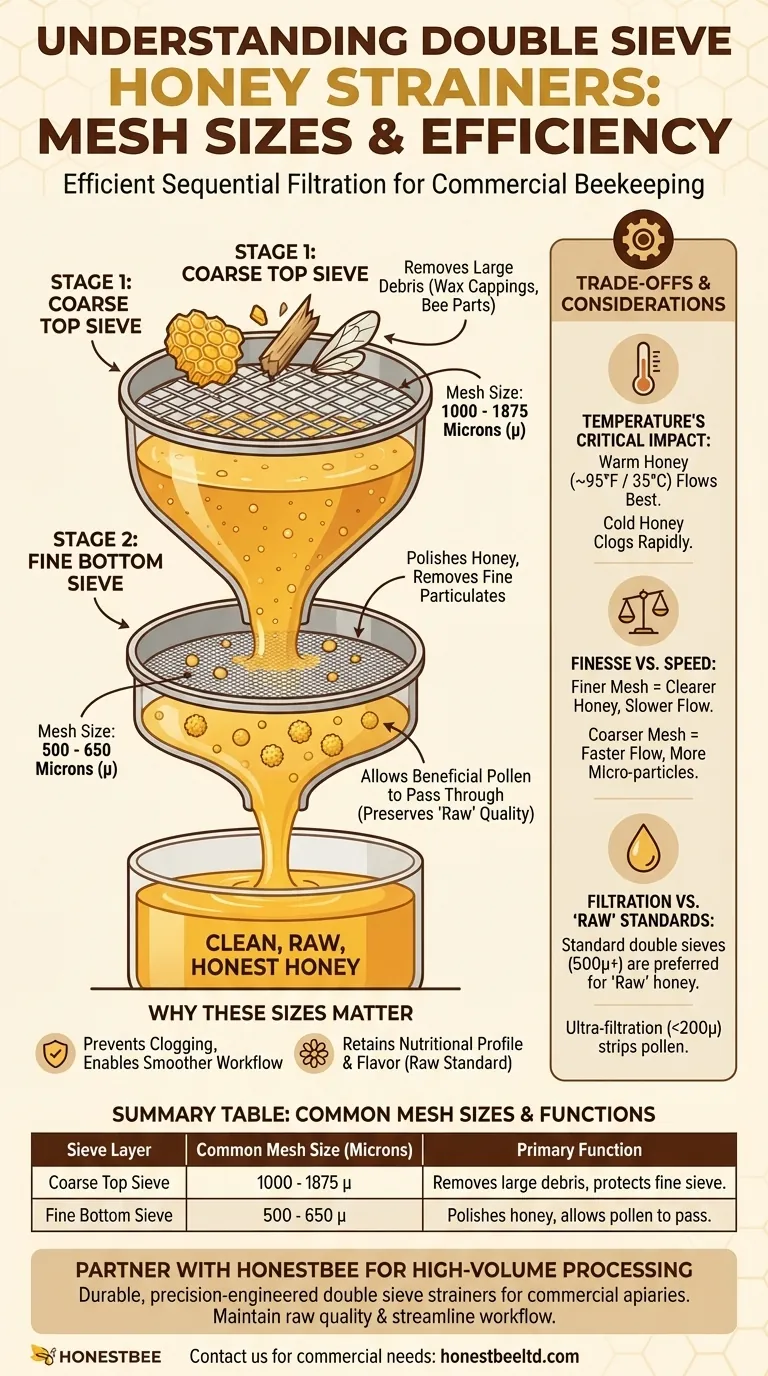

For a standard double sieve honey strainer, you will typically find a coarse top mesh of 1000 to 1875 microns and a finer bottom mesh between 500 and 650 microns. This two-stage system is designed to first catch large debris like wax cappings and bee parts, then filter out smaller particulates, resulting in clean honey without clogging the fine screen immediately.

The core principle is not just filtration, but efficient, sequential filtration. The coarse sieve protects the fine sieve from clogging, allowing for a smoother, faster workflow while achieving the clarity desired by both hobbyists and small-scale producers.

The Mechanics of Two-Stage Straining

A double sieve is a simple but highly effective design. Each component has a specific job, and understanding their roles is key to producing high-quality honey with minimal effort.

The Role of the Coarse Top Sieve

The top, coarser sieve is your first line of defense. With a mesh size typically around 1000 to 1875 microns, its primary job is to catch the largest impurities.

This includes visible debris from the extraction process, such as larger pieces of wax cappings, wood splinters from the hive body, or the occasional bee part. By removing this heavy debris first, it prevents the finer sieve below from becoming instantly blocked.

The Function of the Fine Bottom Sieve

The bottom sieve performs the "polishing" work. Its much finer mesh, usually 500 to 650 microns, is designed to catch smaller suspended particles.

This stage removes fine wax particles and other small impurities that passed through the top screen. The result is honey with excellent clarity and a professional appearance, free from visible specks.

Why These Sizes Preserve Honey Quality

A micron is one-thousandth of a millimeter. The mesh sizes used in these strainers are specifically chosen to clarify the honey without stripping its beneficial components.

Crucially, a 500-micron filter is large enough to allow beneficial pollen grains to pass through. This means the honey can be effectively cleaned while still being considered "raw" and retaining its unique nutritional profile and flavor.

Understanding the Trade-offs

While effective, the process of straining honey is a balance between clarity, speed, and honey characteristics. Being aware of the trade-offs is essential for a smooth operation.

Straining Finesse vs. Clogging Speed

The primary trade-off is simple: a finer mesh produces clearer honey but is more prone to clogging. A coarser mesh allows for faster processing but may leave more microscopic particles.

The double sieve design is the ideal compromise. It mitigates the clogging issue, but the flow rate will still be dictated by the fineness of the bottom screen.

Temperature's Critical Impact

The viscosity of honey is highly dependent on temperature. Warm honey flows thin and fast, while cool honey is thick and slow.

Attempting to strain cool or crystallized honey, even with a standard double sieve, will lead to rapid clogging and significant frustration. For best results, honey should be warmed to around 95°F (35°C) to allow it to pass through the sieves easily.

Filtration vs. "Raw" Honey Standards

Straining is not the same as ultra-filtration. Commercial processors sometimes use high-pressure filters with exceptionally small mesh sizes (under 200 microns) that can strip pollen and other beneficial compounds from honey.

Standard double sieves, with their 500+ micron fine mesh, are the preferred tool for beekeepers who want to produce clean honey that still qualifies as raw and minimally processed.

How to Apply This to Your Goal

Your choice of equipment and process depends on what you want to achieve with your final product.

- If your primary focus is maximum clarity for competition or sale: Use the finer end of the spectrum (e.g., 500-micron bottom mesh) and ensure your honey is properly warmed to facilitate flow.

- If your primary focus is high-speed processing for large batches: A slightly coarser fine mesh (e.g., 650 micron) will improve your flow rate while still producing beautifully clean honey.

- If your primary focus is preserving the "raw" character of the honey: Rest assured that a standard double sieve is the correct tool, as it effectively cleans the honey without removing the pollen that defines its natural quality.

By understanding this two-stage system, you can confidently produce beautifully clear honey that retains its natural character and value.

Summary Table:

| Sieve Layer | Common Mesh Size (Microns) | Primary Function |

|---|---|---|

| Coarse Top Sieve | 1000 - 1875 µ | Removes large debris (wax cappings, bee parts) to protect the fine sieve. |

| Fine Bottom Sieve | 500 - 650 µ | Polishes honey by removing fine particles while allowing beneficial pollen to pass through. |

Ready to produce high-quality, clean honey efficiently?

As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides durable, precision-engineered double sieve honey strainers designed for high-volume, reliable performance. Our equipment helps you maintain the raw quality of your honey while streamlining your processing workflow.

Contact our team today to discuss your commercial straining needs and explore our full range of beekeeping supplies.

Visual Guide

Related Products

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- How does a multi-layer stainless steel honey strainer improve quality? Ensure Pure, Professional-Grade Honey Results

- What is a steel strainer used for? A Kitchen Essential for Precision & Hygiene

- What is the primary purpose of honey filters? Achieve Professional Clarity & Pure Honey Quality

- What are some typical mesh size combinations found in double sieve honey strainers? Expert Guide to Honey Filtration

- What are the key features of a double sieve honey strainer? Achieve Fast, Clean Honey Processing