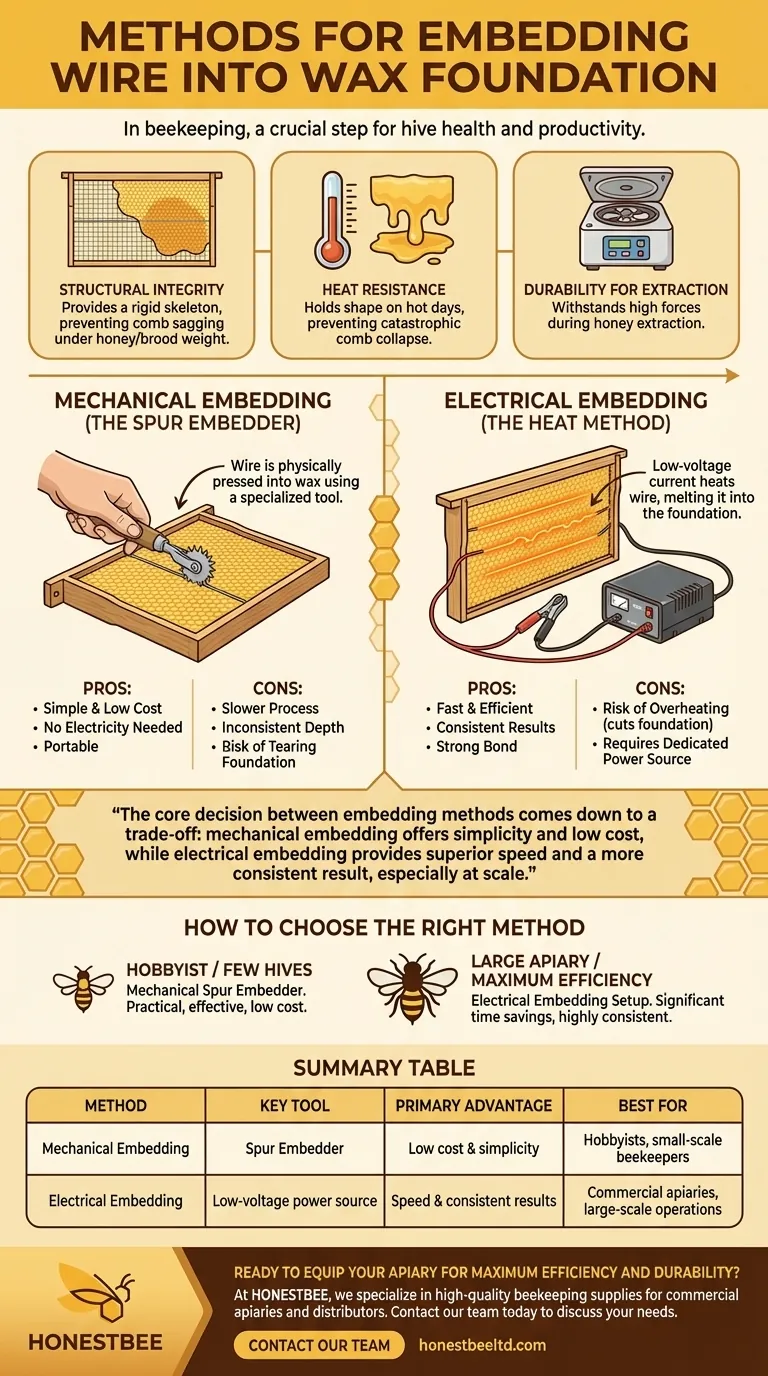

In beekeeping, there are two primary methods for embedding support wire into a wax foundation. The wire can be physically pressed into the wax using a specialized tool, or it can be heated with a low-voltage electric current, which causes it to melt its way into the foundation.

The core decision between embedding methods comes down to a trade-off: mechanical embedding offers simplicity and low cost, while electrical embedding provides superior speed and a more consistent result, especially at scale.

The Purpose of Wiring a Foundation

Before examining the methods, it's essential to understand why this step is so critical for the health and productivity of a beehive.

Structural Integrity

Wiring provides a rigid skeleton for the soft beeswax foundation. This prevents the comb from sagging or warping, especially under the weight of honey and brood.

Heat Resistance

On hot days, beeswax can become very soft. A wired foundation holds its shape, preventing a catastrophic collapse of the comb, which could kill brood and spill honey throughout the hive.

Durability for Extraction

The wiring provides the strength needed for the comb to withstand the high centrifugal forces of a honey extractor. Without it, the delicate comb would likely disintegrate during the extraction process.

A Closer Look at Embedding Methods

Both methods achieve the same goal but use fundamentally different approaches. The right choice depends on your scale, budget, and preference.

Mechanical Embedding (The Spur Embedder)

This manual method uses a tool that resembles a small pastry cutter or a spurred wheel, known as a spur embedder.

The process involves laying the wired frame over the sheet of wax foundation. You then roll the spur embedder along the wire, applying firm, even pressure to physically press and crimp the wire into the wax.

Electrical Embedding (The Heat Method)

This method uses a low-voltage power source, such as a dedicated transformer or a 12V battery charger, to heat the wire.

The ends of the wire in the frame are connected to the power source for just a few seconds. The electric current heats the wire, causing it to melt the wax around it and sink perfectly into the foundation. Once the current is removed, the wax cools and solidifies around the wire.

Understanding the Trade-offs and Pitfalls

Neither method is universally superior; each comes with distinct advantages and potential challenges that are important to consider.

The Simplicity of Mechanical Tools

The primary advantage of a spur embedder is its simplicity. It's inexpensive, requires no electricity, and is easy to use anywhere.

However, this method is significantly slower than its electrical counterpart. It can also be difficult to achieve a perfectly consistent depth, and applying too much pressure can tear or damage the fragile foundation.

The Efficiency of Electrical Embedders

Electrical embedding is exceptionally fast and efficient, allowing a beekeeper to process many frames in a short amount of time. It creates a very clean, consistent, and secure bond as the wax melts perfectly around the wire.

The main pitfall is the risk of overheating. Leaving the current on for even a second too long can cause the wire to melt straight through the foundation, cutting it in half. This requires a bit of practice to perfect the timing. It also necessitates a dedicated power source.

How to Choose the Right Method

Your choice should align directly with the scale and goals of your beekeeping operation.

- If you are a hobbyist with just a few hives: The low cost and simplicity of a mechanical spur embedder make it a practical and effective choice.

- If you manage a larger apiary or value maximum efficiency: Investing in an electrical embedding setup will save a significant amount of time and produce highly consistent results.

Ultimately, both methods lead to a strong, durable comb that provides the ideal structure for your bees to build upon.

Summary Table:

| Method | Key Tool | Primary Advantage | Best For |

|---|---|---|---|

| Mechanical Embedding | Spur Embedder | Low cost & simplicity | Hobbyists, small-scale beekeepers |

| Electrical Embedding | Low-voltage power source | Speed & consistent results | Commercial apiaries, large-scale operations |

Ready to equip your apiary for maximum efficiency and durability?

At HONESTBEE, we specialize in supplying high-quality beekeeping supplies and equipment to commercial apiaries and distributors through our wholesale-focused operations. Whether you need reliable spur embedders for your team or efficient electrical embedding systems to scale your production, we have the tools and expertise to support your success.

Contact our team today to discuss your specific needs and discover how our products can help you build stronger, more productive hives.

Visual Guide

Related Products

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- HONESTBEE Adjustable Voltage Wire Embedder with Digital Display

- HONESTBEE professional Efficient Beekeeping Tool: Electric Spur Wheel Wire Embedder

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How does the adoption of self-fertile almond varieties impact beekeeping equipment? Navigating the Strategic Shift

- Why are hot wires or specialized cutting tools required for Top Bar Hive comb management? Master Hive Structural Integrity

- How does the frame wiring jig assist in running horizontal wires through frames? Streamline Your Beekeeping Setup

- How can combs be further strengthened? Embed Wires for Durable, High-Yield Hives

- What should be done to the sidebars if wiring the frames? A Guide to Drilling Holes for Maximum Frame Strength