To safely melt beeswax in a microwave, you must use very short heating intervals of no more than one minute at a time. After each interval, allow the wax to cool for 20-30 seconds before stirring it thoroughly. This prevents superheating, a dangerous condition where the liquid can erupt and splatter violently.

While using a microwave is possible with extreme caution, the significant risk of fire and splattering makes it an ill-advised method. The professional standard is to use gentle, indirect heat—such as a double boiler or crock pot—which provides far greater control and safety.

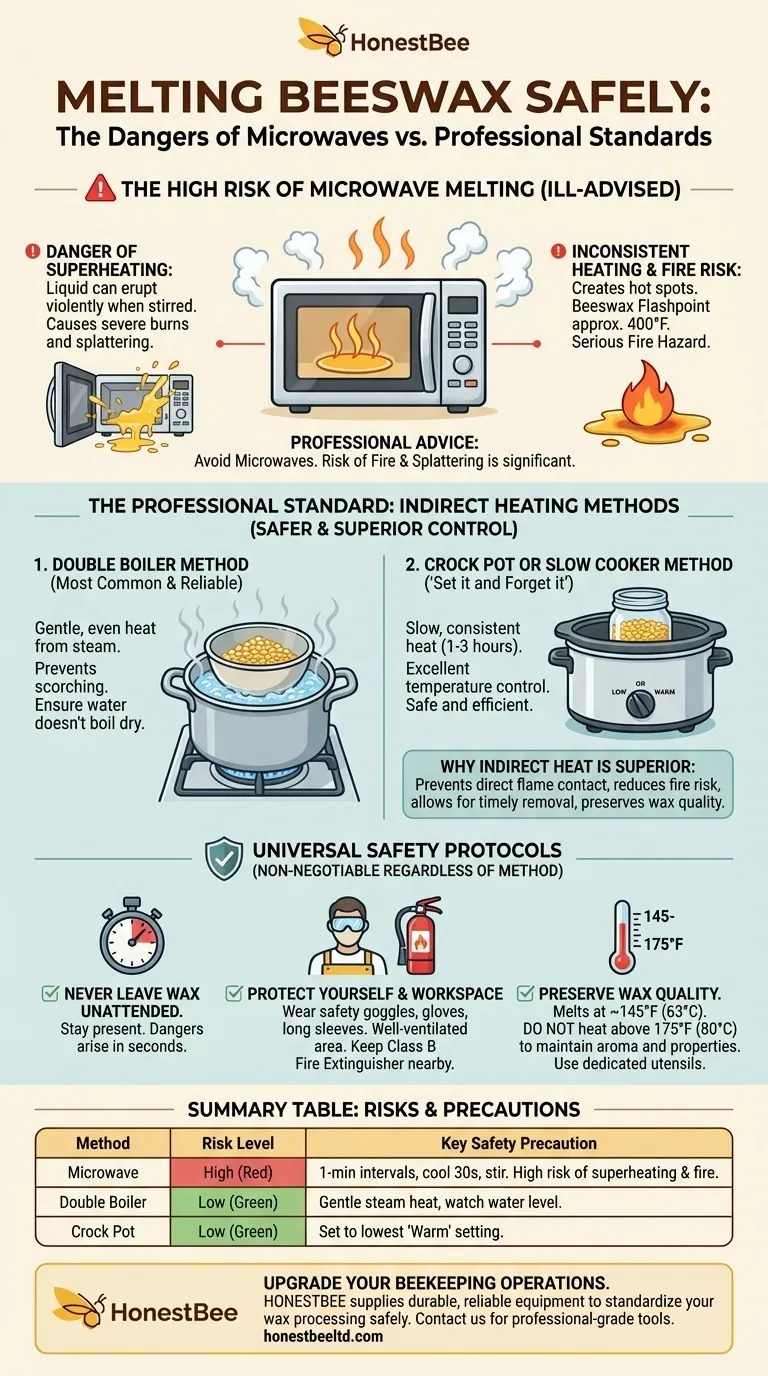

The High Risk of Microwave Melting

Using a microwave to melt beeswax introduces unique dangers that are difficult to control. The primary concern is not just overheating, but the specific way microwaves heat liquids.

The Danger of Superheating

Microwaves can heat water molecules within the wax past their boiling point without visible signs of boiling. Any disturbance, like stirring, can cause the liquid to erupt violently.

This sudden splattering can cause severe burns and create a significant mess inside your appliance.

Inconsistent Heating and Fire Risk

Microwaves often create hot spots, heating some parts of the wax far more than others. This makes it easy to scorch the wax, which darkens its color, reduces its aroma, and can destroy its beneficial properties.

Most importantly, beeswax is flammable, with a flashpoint around 400°F. An uncontrolled hot spot in a microwave can easily become an ignition source, creating a serious fire hazard.

The Professional Standard: Indirect Heating Methods

To avoid the risks of direct or microwave heat, professionals rely on gentle, indirect heating. This approach gives you maximum control over the temperature, ensuring safety and preserving the quality of the wax.

The Double Boiler Method

A double boiler is the most common and reliable method. You place a smaller pot or heat-safe bowl containing the beeswax over a larger pot with simmering water.

The steam from the water provides gentle, even heat, melting the wax slowly and safely. Always ensure the water in the bottom pot does not boil away completely.

The Crock Pot or Slow Cooker Method

A crock pot or dedicated slow cooker is an excellent "set it and forget it" option. Place the beeswax in a heat-safe container inside the crock pot.

Set the appliance to its lowest setting ("Low" or "Warm"). This method provides very slow, consistent heat over 1-3 hours, making it one of the safest options available.

Why Indirect Heat is Superior

Indirect heat ensures the beeswax never comes into contact with a direct flame or a high-temperature heating element. This prevents scorching and dramatically reduces the risk of fire.

It also allows you to remove the wax from the heat source the moment it is fully melted, preventing unnecessary overheating.

Universal Safety Protocols (Regardless of Method)

No matter how you choose to melt your beeswax, certain safety precautions are non-negotiable.

Never Leave Wax Unattended

This is the single most important rule. A situation can become dangerous in seconds. Always stay present and monitor the melting process from start to finish.

Protect Yourself and Your Workspace

Hot wax can cause severe burns. Always wear safety gear, including safety goggles, gloves, and a long-sleeved shirt.

Work in a well-ventilated area to avoid inhaling fumes and always keep a fire extinguisher rated for grease fires (Class B) nearby.

Preserve the Wax Quality

Beeswax melts at approximately 145°F (63°C). To preserve its natural color, aroma, and anti-microbial properties, do not heat it above 175°F (80°C).

Using dedicated pots and utensils for your beeswax work is also highly recommended to prevent cross-contamination and simplify cleanup.

How to Apply This to Your Project

Your choice of method depends on your priorities and the frequency with which you work with wax.

- If you absolutely must use a microwave for a tiny amount: Follow the one-minute interval rule with extreme diligence and accept the inherent risks.

- If your primary focus is safety and quality (the recommended approach): Use a double boiler for active melting or a crock pot for a slower, hands-off process.

- If you plan to work with wax regularly: Consider investing in a dedicated, temperature-controlled wax melter for ultimate convenience and safety.

By prioritizing gentle, controlled heat and constant supervision, you ensure a safe process that preserves the unique qualities of your beeswax.

Summary Table:

| Method | Risk Level | Key Safety Precaution |

|---|---|---|

| Microwave | High | Use 1-minute intervals, stir after cooling 30 seconds. High risk of superheating and fire. |

| Double Boiler | Low | Use gentle steam heat, ensure water doesn't boil dry. |

| Crock Pot | Low | Set to lowest 'Warm' setting for slow, even melting. |

| Universal Rules | Critical | Never leave wax unattended. Wear gloves & goggles. Keep a Class B fire extinguisher nearby. |

Upgrade Your Beekeeping Operations with Professional-Grade Equipment

Melting beeswax safely and efficiently is crucial for producing high-quality products. For commercial apiaries and distributors, relying on risky methods like a microwave is not a scalable or safe solution.

HONESTBEE supplies the durable, reliable equipment you need to standardize your wax processing safely. We provide wholesale-focused solutions for beekeepers who demand quality and efficiency.

Let us help you equip your operation with the right tools for the job.

Contact HONESTBEE today to discuss your equipment needs and our wholesale pricing.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- Metal Queen Bee Excluder for Beekeeping

- Commercial 48-Frame Stainless Steel Honey Extractor

People Also Ask

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- What is beeswax and why is it valuable? Discover Its Versatility for Your Business

- What is the final step in making beeswax foundation sheets? Achieving Perfect Fit for a Productive Hive

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- How does the machine flatten the beeswax? A Guide to Roller and Press Methods