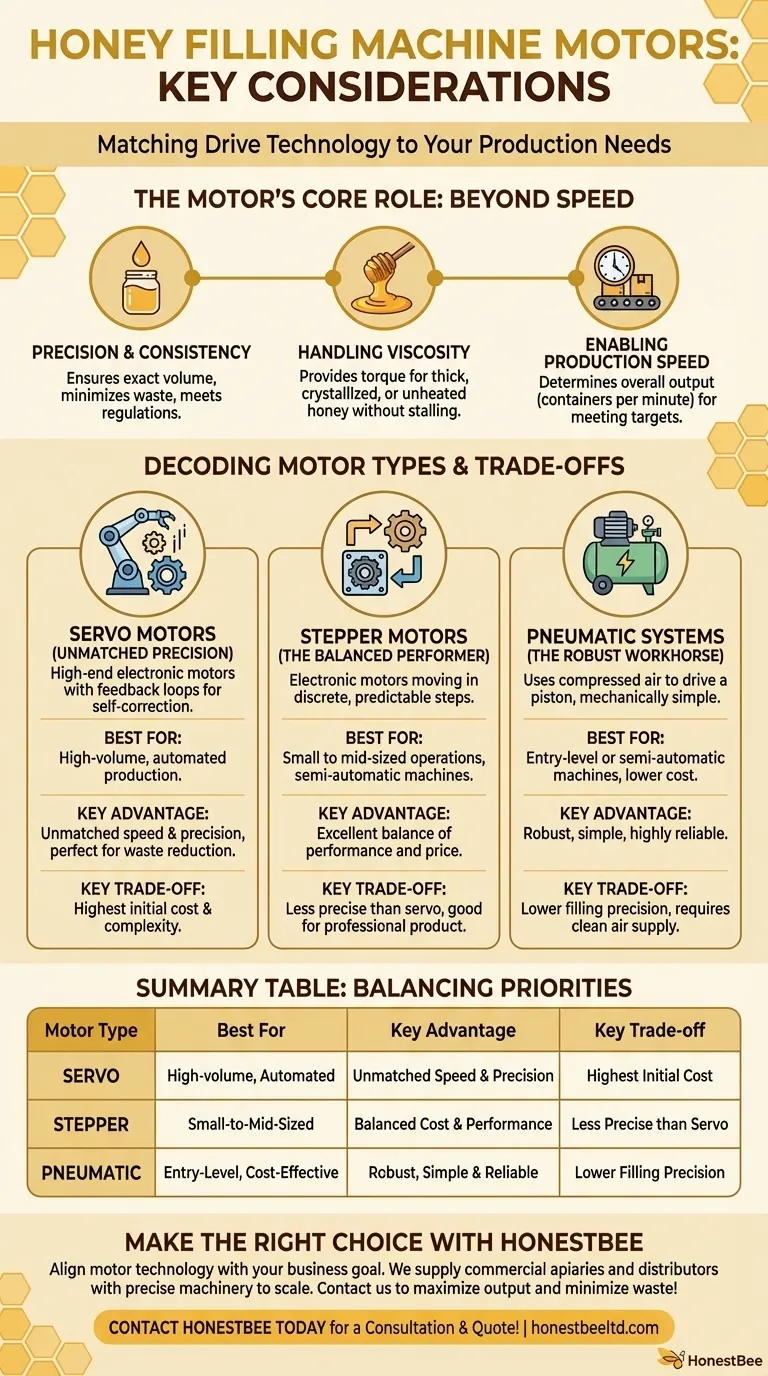

When considering a honey filling machine, the motor is the core component that dictates the machine's speed, filling accuracy, and its ability to handle different honey viscosities. The right motor system ensures consistent product delivery and operational efficiency, directly impacting your production capacity and product quality.

Your decision isn't about finding the single "best" motor, but about matching the drive technology—typically a Servo Motor, Stepper Motor, or Pneumatic System—to your specific operational needs for production volume, filling precision, and honey consistency.

Beyond Speed: The Motor's True Role

While production speed is an obvious benefit, the motor or actuator system is responsible for much more. It is the heart of the machine's performance, controlling the three most critical variables in the filling process.

Driving Precision and Consistency

The primary job of the motor system is to actuate a pump or piston, dispensing a precise volume of honey. A high-quality control system ensures each and every container is filled to the exact same level, minimizing product waste and ensuring regulatory compliance.

Handling Honey's Viscosity

Honey's thickness, or viscosity, varies dramatically with temperature and floral source. A powerful motor provides the necessary torque to push thick, crystallized, or unheated honey through the filling nozzle without slowing down or stalling, ensuring a smooth and continuous operation.

Enabling Production Speed

The motor's ability to complete a fill cycle quickly and reliably determines the machine's overall output, measured in containers per minute. For large-scale operations, a motor capable of high-speed, repeatable cycles is non-negotiable for meeting production targets.

Decoding Motor and Actuator Types

Honey filling machines don't all use the same type of motor. The technology used is a direct reflection of the machine's intended application, precision, and cost. Understanding the three common types is key to making an informed choice.

Servo Motors: For Unmatched Precision and Speed

Servo motors are high-end electronic motors that offer exceptional control over position, speed, and torque. They use a feedback loop to continuously self-correct, ensuring every fill is identical.

These are the standard for fully automatic, high-throughput lines where waste reduction and maximum speed are critical. While they represent a higher initial investment, their performance justifies the cost for large-scale producers.

Stepper Motors: The Balanced Performer

Stepper motors are also electronic and offer good precision by moving in discrete, predictable steps. They are simpler and more cost-effective than servo motors, providing an excellent balance of performance and price.

This technology is ideal for small to mid-sized operations and semi-automatic machines. They provide the accuracy needed for a professional product without the high cost of a full servo system.

Pneumatic Systems: The Robust Workhorse

Instead of an electric motor, these systems use compressed air to drive a piston, forcing the honey out. Pneumatic actuators are mechanically simple, powerful, and highly reliable.

They are a common choice for entry-level or semi-automatic machines due to their lower cost and durability. Their primary trade-off is slightly lower filling precision compared to servo or stepper systems, as the flow of air is harder to control with pinpoint accuracy.

Understanding the Trade-offs

Choosing a motor system is a matter of balancing priorities. No single option is perfect for every scenario; you must weigh the benefits against the downsides for your specific business.

Cost vs. Performance

There is a clear hierarchy in cost and performance. Servo motors are the most expensive but deliver the highest accuracy and speed. Pneumatic systems are the most affordable but offer the least precision. Stepper motors sit comfortably in the middle.

Precision vs. Simplicity

A servo system's complexity allows for incredible precision but may require more technical skill for setup and maintenance. A pneumatic system is mechanically simple and easy to troubleshoot but won't deliver the same gram-level accuracy.

Maintenance and Environment

Pneumatic systems require a clean, dry air supply to prevent valve and cylinder failure. Servo and stepper motors are electronic and must be protected from moisture and excessive heat, but they do not require an external air compressor.

Making the Right Choice for Your Operation

To select the right machine, align the motor technology with your primary business goal.

- If your primary focus is high-volume, automated production: A servo motor system is the superior choice for its unmatched speed and repeatable accuracy.

- If you are a small-to-mid-sized producer needing flexibility and precision: A stepper motor offers the best balance of performance and cost for most semi-automatic lines.

- If your primary focus is a simple, cost-effective, and durable machine: A pneumatic system is a robust and reliable workhorse, especially if absolute pinpoint accuracy is a secondary concern.

By understanding how the drive system aligns with your product and production goals, you can invest confidently in a machine that will be a long-term asset for your business.

Summary Table:

| Motor Type | Best For | Key Advantage | Key Trade-off |

|---|---|---|---|

| Servo Motor | High-volume, automated production | Unmatched speed & precision | Highest initial cost |

| Stepper Motor | Small-to-mid-sized operations | Excellent balance of cost & performance | Less precise than servo |

| Pneumatic System | Cost-effective, durable machines | Robust, simple, and reliable | Lower filling precision |

Ready to optimize your honey production line?

Choosing the right filling machine motor is critical for your efficiency and profitability. At HONESTBEE, we specialize in supplying commercial apiaries and beekeeping equipment distributors with the precise machinery they need to scale. Our experts can help you select the perfect motor system—servo, stepper, or pneumatic—to match your production volume, honey viscosity, and accuracy requirements.

Let us provide you with reliable, high-performance equipment that maximizes your output and minimizes waste.

Contact HONESTBEE today for a personalized consultation and wholesale quote!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

People Also Ask

- How does automated honey sampling and filling equipment assist in safety evaluations? Ensure Lab-Grade Data Integrity

- What role do automated honey filling machines play? Boost Profits and Brand Value in Your Honey Business

- What technical value do industrial honey-filling and processing equipment add to the honey value chain? Elevate Quality

- What role do automatic honey-filling machines play in the commercial packaging of honey? Scaling for Global Markets

- How does the filling station work in a honey stick machine? Achieve Perfect Fill Accuracy

- What factors must industrial equipment manage for Manuka honey? Preserve MGO & UMF with Precision Filling

- What are the benefits of using automated honey filling machines? Scale Your Production and Ensure Product Purity

- What is the role of automated filling and packaging equipment? Transform Bulk Honey into High-Value Retail Brands