When selecting combs for honey extraction, the most critical factor is ensuring the honey is "cured" and ready. The bees provide a clear signal for this: a complete wax cap over the cells. Harvesting fully capped frames is the single most important step to guarantee a high-quality, shelf-stable product.

The core principle of comb selection is moisture control. Selecting capped honeycomb is not just a best practice; it is a fundamental requirement to prevent fermentation and spoilage, thereby protecting the integrity of your entire honey harvest.

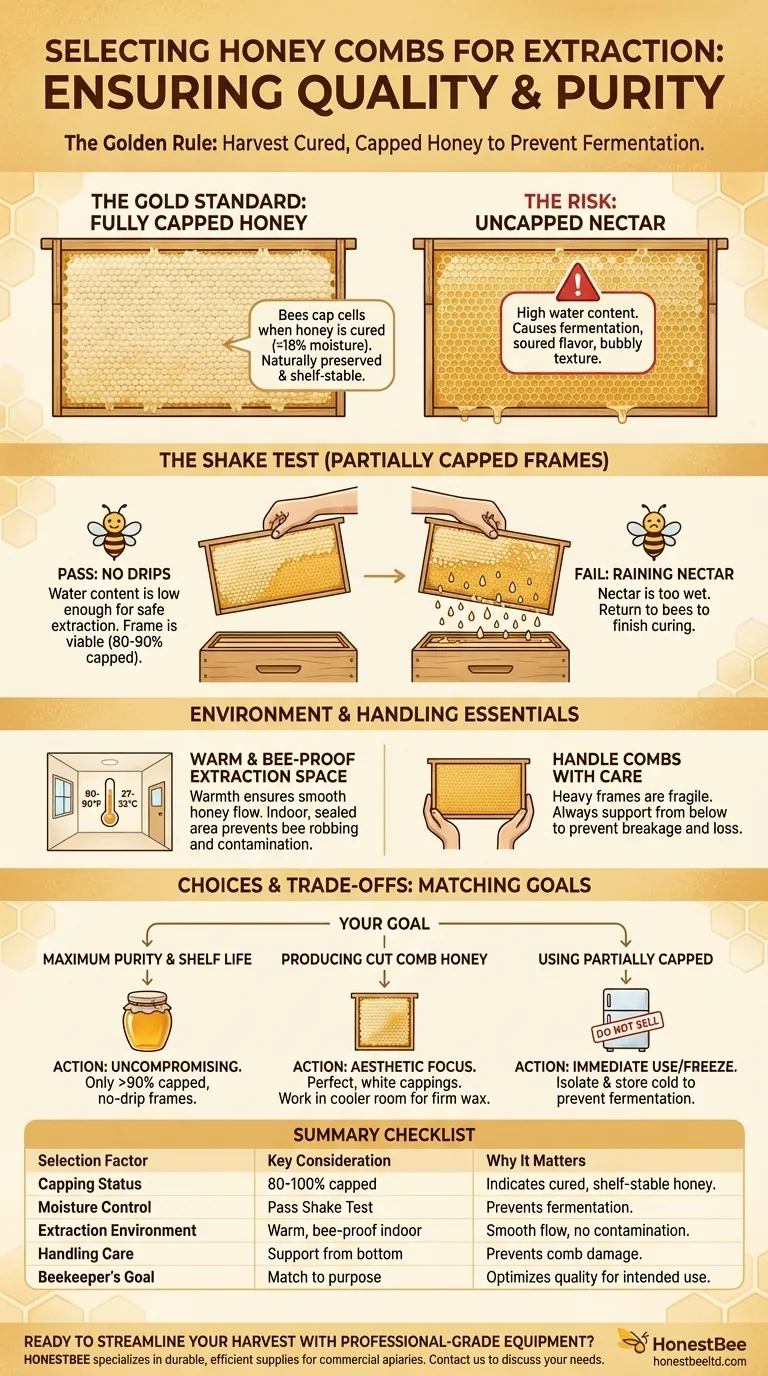

The Primary Selection Criterion: Moisture Content

The entire decision-making process for selecting a comb hinges on one variable: the water content of the nectar inside. Bees are masters at managing this, and your job is to recognize when they have finished their work.

Why Capped Honey is the Gold Standard

Bees only cap cells of honey when they have successfully reduced the water content to approximately 18%. They achieve this by fanning their wings and circulating air within the hive.

This low moisture level is crucial because it makes the honey an inhospitable environment for wild yeasts and bacteria. Capped honey is naturally preserved and will not ferment.

The Risk of Uncapped Nectar

Uncapped cells contain nectar that has not yet been fully dehydrated. This nectar has a high water content, which can easily introduce enough moisture to your batch to trigger fermentation.

Even a small number of uncapped cells can compromise an entire container of extracted honey, leading to a soured, bubbly, and unusable product.

The "Shake Test" for Partially Capped Frames

A frame does not always need to be 100% capped to be viable. A common rule of thumb is to look for frames that are at least 80-90% capped.

To test a partially capped frame, hold it horizontally over the open hive and give it a firm, downward shake. If no nectar or honey drips out, the water content is likely low enough for safe extraction. If it "rains" nectar, the frame should be returned to the bees to finish their work.

Environmental and Handling Considerations

Beyond the state of the comb itself, the environment and your handling process play a significant role in a successful harvest.

Choosing Your Extraction Space

Your extraction area must be clean, dry, and completely sealed from bees. The powerful aroma of honey can travel a great distance and will attract bees from your own and neighboring apiaries, which can lead to robbing and agitated colonies.

Work indoors, far from the hive, and ensure all windows and doors are closed.

The Role of Temperature

The ambient temperature of your extraction room directly impacts the viscosity of the honey.

A warm room (around 80-90°F or 27-32°C) is highly beneficial. Warm honey flows more freely, making it much easier to uncap the cells and spin the honey out of the comb in an extractor.

Careful Handling of Fragile Combs

Always handle frames with care. Some combs may be exceptionally heavy with honey or attached to the frame flimsily.

Dropping a full frame of honey creates a significant mess and represents a loss of hard work—both yours and the bees'. Support frames from the bottom when moving them.

Understanding the Trade-offs

Every beekeeper faces the choice between maximizing their harvest and ensuring its quality. Understanding the risks associated with this choice is key.

The Temptation of "Almost-Ready" Frames

It is tempting to pull frames that are heavy but only partially capped to increase your total yield. This is a significant gamble.

The risk of spoiling your entire harvest with high-moisture honey almost always outweighs the benefit of a few extra pounds. Discipline at this stage is the hallmark of an experienced beekeeper.

How Extraction Method Influences Selection

For beekeepers using a centrifugal spinner (extractor), a well-built, fully-drawn comb is ideal.

If you are using a "crush and strain" method, the structural integrity of the comb is less important, as you will be breaking it up anyway. However, the requirement for the honey to be fully capped and cured remains exactly the same regardless of your method.

Making the Right Choice for Your Goal

Your specific goal for the honey can help guide your selection process on the margins.

- If your primary focus is maximum purity and shelf life: Be uncompromising. Only harvest frames that are at least 90% capped and pass the shake test with zero drips.

- If your primary focus is producing cut comb honey: Select frames that are perfectly and evenly drawn with pristine white cappings. Work in a cooler room to keep the wax firm and prevent the delicate comb from becoming floppy.

- If you must use partially capped frames: Isolate the honey extracted from these frames. Plan to use it immediately or store it in a freezer to prevent fermentation, as it is not shelf-stable.

Ultimately, proper comb selection is about respecting the natural process of the bees to protect the final quality of your honey.

Summary Table:

| Selection Factor | Key Consideration | Why It Matters |

|---|---|---|

| Capping Status | Look for 80-100% capped cells. | Indicates honey is cured (≈18% moisture) and shelf-stable. |

| Moisture Control | Perform the shake test on partially capped frames. | Prevents fermentation by avoiding high-moisture nectar. |

| Extraction Environment | Work in a warm (80-90°F), bee-proof, indoor space. | Ensures honey flows easily and avoids contamination. |

| Handling Care | Support frames from the bottom when moving. | Prevents comb damage and loss of valuable honey. |

| Beekeeper's Goal | Match selection to purpose (e.g., cut comb vs. liquid honey). | Optimizes quality and yield based on intended use. |

Ready to streamline your honey harvest with professional-grade equipment?

As HONESTBEE, we specialize in supplying durable, efficient beekeeping supplies and extraction equipment to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable tools needed to maintain honey quality and increase your yield.

Contact our team today to discuss your equipment needs and discover how we can support your beekeeping success.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

People Also Ask

- How long does an electric honey extractor take? Drastically Cut Your Harvest Time & Effort

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- Why do beekeepers have to lift a lot of weight at the end of a growing season? The Reward of a Heavy Harvest

- What to do with wet frames after extracting honey? Let Your Bees Clean Them for Best Results

- What are radial honey extractors and what are their features? Maximize Your Honey Harvest Efficiency