Once your beeswax has fully melted, you must immediately remove it from the heat source and pour it. This is a critical, time-sensitive step, as the wax will begin to solidify very quickly once it starts to cool. Depending on your project, you will either pour it directly into prepared molds or mix it with other ingredients like oils and butters.

The most common mistake when working with beeswax is underestimating how rapidly it transitions from liquid back to solid. Your primary goal is to have everything prepared before the wax melts, allowing you to act decisively in the short window when the wax is in its ideal liquid state.

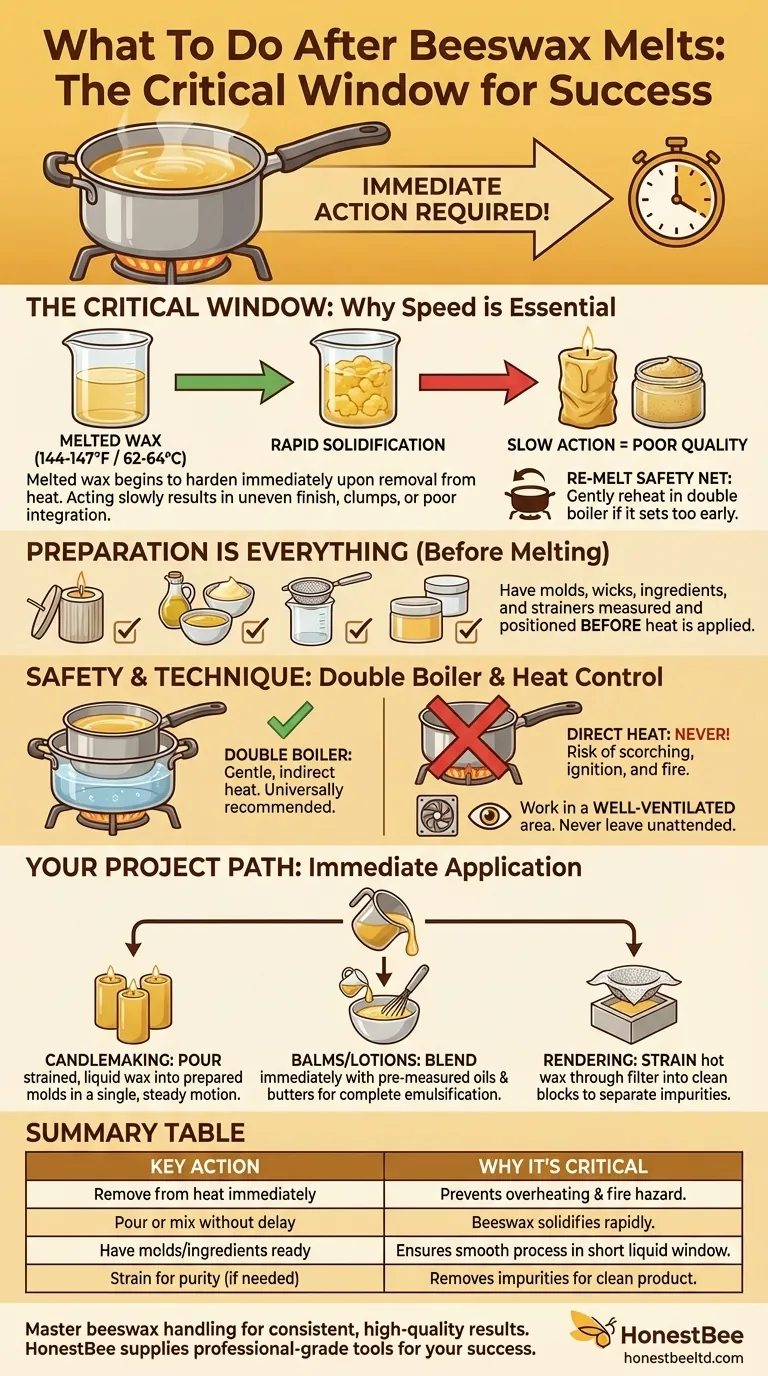

The Critical Window: Why Speed is Essential

Once beeswax liquefies, you are working against the clock. Understanding the properties of the material is key to a successful outcome.

The Solidification Process

Melted beeswax has a relatively high melting point (around 144-147°F or 62-64°C) and will begin to harden almost as soon as it is removed from a heat source.

Acting slowly can result in an uneven finish, premature hardening in your pouring pot, or poor integration with other ingredients.

The Goal: Preserving Fluidity

The objective is to transfer the liquid wax into its final form—be it a candle mold, a container for a balm, or a mixture with oils—while it is still completely fluid.

This ensures a smooth, uniform product without lines, clumps, or separation that can occur if the wax starts to cool too early.

The Re-Melt Safety Net

If your wax begins to set before you are finished pouring or mixing, do not panic. You can gently place it back on your heat source (preferably a double boiler) and re-melt it without damaging the wax.

Preparing for a Clean and Effective Pour

Success is determined by the preparation you do before the wax even touches the heat. A smooth process depends on having everything in place.

Straining for Purity

If you are melting raw beeswax, especially directly from honeycomb cappings, it will likely contain particulates and impurities.

For a clean final product, you must strain the hot wax through a cheesecloth or a fine-mesh filter before pouring it into your final molds. This should be done quickly, as the wax can solidify on the filter.

Understanding the Color Change

As it melts, beeswax becomes translucent and nearly clear, regardless of its original white, yellow, or amber color. This is a normal physical change.

Do not be alarmed by this transparency. The wax will revert to its original opaque color as it cools and solidifies.

Having Molds and Ingredients Ready

Your molds, wicks, containers, and any other ingredients (like carrier oils or butters for cosmetics) must be measured, prepared, and positioned for use before you begin melting the wax.

Understanding the Trade-offs and Safety

Handling hot wax requires a focus on safety and an understanding of the risks involved. Your technique has a direct impact on both safety and final quality.

Direct Heat vs. Double Boiler

Never melt beeswax directly in a pot over a flame or an electric burner. Beeswax is flammable and can easily scorch or ignite if its temperature is not controlled.

Using a double boiler (or a pot set inside another pot of simmering water) is the universally recommended method. It provides gentle, indirect heat that prevents overheating and fire risk.

The Risk of Overheating

Overheated beeswax can release fumes and has a flashpoint where it can ignite. Always work in a well-ventilated area and never leave melting wax unattended.

Using a dedicated crockpot on a low setting is another safe alternative, but a double boiler offers more precise temperature control.

Working Too Slowly

The primary trade-off for not acting quickly is product quality. A rushed pour can be messy, but a slow pour can ruin the product. A wrinkled candle surface or a grainy lotion is often the result of the wax cooling unevenly during the pouring or mixing stage.

How to Apply This to Your Project

Your immediate action after the wax melts depends entirely on your end goal.

- If your primary focus is candlemaking: Immediately pour the strained, liquid wax into your prepared and wicked molds in a single, steady motion.

- If your primary focus is making balms or lotions: Immediately remove the wax from heat and blend it with your pre-measured oils and butters to ensure complete emulsification.

- If your primary focus is rendering raw wax: Immediately strain the hot wax through a filter into clean blocks or storage containers to separate the pure wax from impurities before it solidifies.

By understanding the properties of beeswax, you can confidently control the process from solid to liquid and back again.

Summary Table:

| Key Action | Why It's Critical |

|---|---|

| Remove from heat immediately | Prevents overheating and potential fire hazard. |

| Pour or mix without delay | Beeswax begins to solidify rapidly once cooling starts. |

| Have molds/ingredients ready | Ensures a smooth process during the short liquid window. |

| Strain for purity (if needed) | Removes impurities from raw wax for a clean final product. |

Achieve flawless results in your beekeeping product creation.

Mastering the handling of beeswax is essential for producing high-quality candles, balms, and more. As a commercial beekeeper or distributor, the quality of your supplies directly impacts your final products and efficiency.

HONESTBEE supplies professional-grade beekeeping supplies and equipment through wholesale-focused operations. We provide the reliable tools you need to work confidently with materials like beeswax, ensuring consistency and quality in your operations.

Ready to upgrade your beekeeping equipment? Contact our wholesale team today to discuss your needs and discover how our products can support your business's success.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

People Also Ask

- Why is it important to heat honey slowly and evenly? Preserve Flavor, Nutrients & Value

- What is the water bath method for honey processing? A Gentle Technique for Quality Honey

- How to permanently decrystallize honey? Embrace Its Natural State for Maximum Quality

- What is melter honey used for? A Low-Cost Ingredient for Bakers and Brewers

- What equipment is commonly used for heating and processing honey? Essential Tools for Every Beekeeper