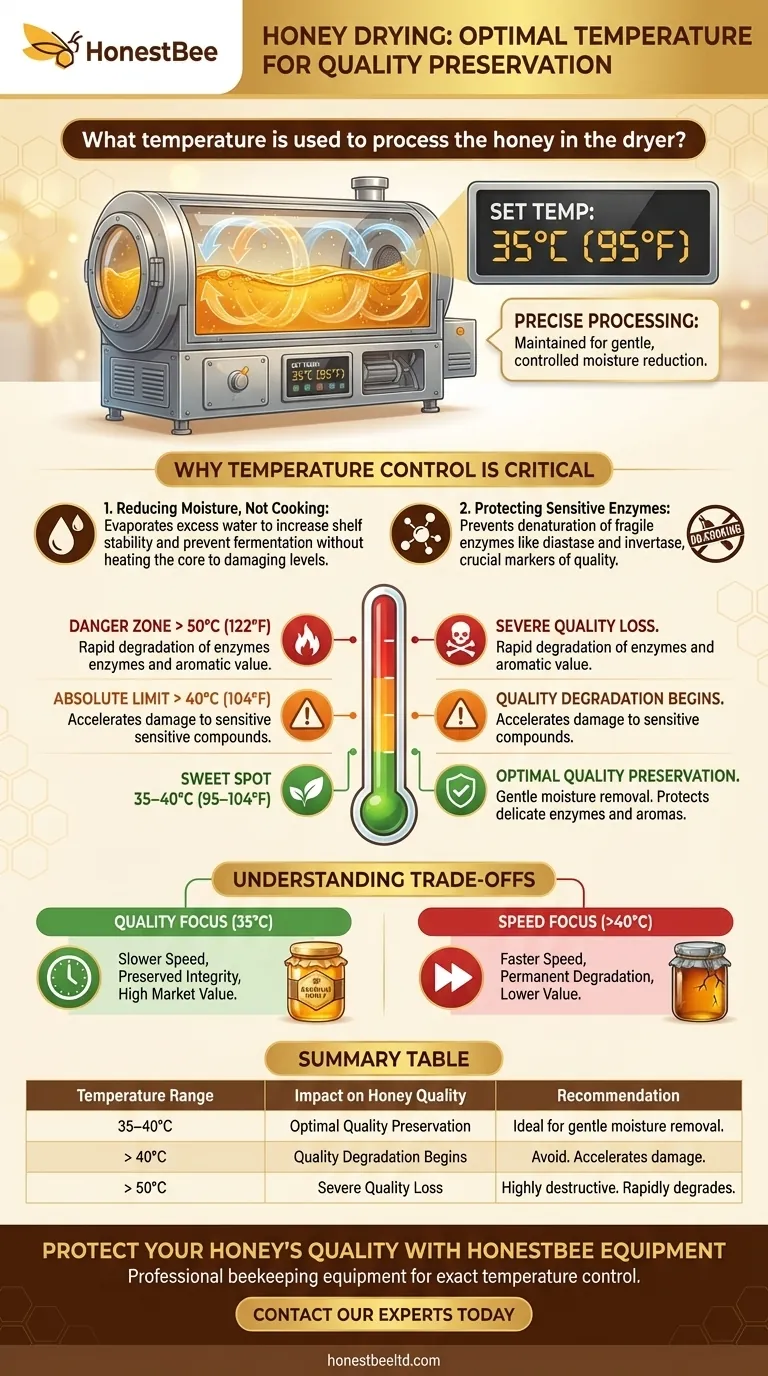

For this specific process, the honey is processed at a precise temperature of 35°C (95°F). This temperature is maintained by the heating system incorporated within the drying machine to ensure a gentle and controlled reduction of moisture content.

The central principle of drying honey is to remove excess water without "cooking" the product. Exceeding the optimal temperature range irreversibly degrades the enzymes and sensitive compounds that define high-quality, natural honey.

Why Temperature Control is Critical for Honey Quality

Honey is a complex biological substance, not an inert sugar syrup. Its value lies in delicate enzymes, aromas, and other compounds that are highly sensitive to heat. The goal of a honey dryer is to reduce the water content, not alter its fundamental composition.

The Goal: Reducing Moisture, Not Cooking

The primary purpose of the dryer is to gently evaporate water from the honey. This process increases its shelf stability and prevents fermentation.

This is achieved by creating a temperature differential and circulating air, allowing water to escape without raising the honey's core temperature to a damaging level.

Protecting Sensitive Enzymes

Honey contains beneficial enzymes like diastase and invertase, which are often used as markers for its quality and rawness. These proteins are fragile.

Heating honey, even to moderate temperatures, begins to denature these enzymes, effectively destroying their structure and function. The 35-40°C range is chosen to minimize this degradation.

Understanding the Optimal Temperature Range

While the machine is set to 35°C, it's important to understand the thresholds that guide this decision. The window for safe and effective drying is narrow.

The "Sweet Spot": 35–40°C (95–104°F)

This is considered the optimal temperature range for drying honey. It provides enough warmth to facilitate moisture evaporation efficiently without causing significant harm to the honey's delicate profile.

Operating within this range balances processing speed with quality preservation.

The Absolute Limit: Do Not Exceed 40°C (104°F)

Exceeding 40°C is the point where damage to sensitive substances begins to accelerate. While the drying process may be faster, it comes at the cost of the honey's intrinsic quality.

This temperature should be viewed as a strict upper boundary for any high-quality honey processing operation.

The Danger Zone: Above 50°C (122°F)

Processing honey at temperatures above 50°C is highly destructive. At this point, the reduction of enzymes and other valuable substances becomes rapid and severe.

This level of heat fundamentally changes the honey, diminishing its nutritional and aromatic value.

Understanding the Trade-offs

Choosing the right temperature is a conscious decision that balances efficiency against the final quality of the product. There is no shortcut to preserving quality.

Speed vs. Quality

It may be tempting to increase the temperature to dry the honey faster. However, any time saved is lost in the permanent degradation of the product.

The 35°C setting represents a deliberate choice to prioritize quality over speed.

Consistency and Control

Using a machine with an integrated and controlled heating system is critical. It ensures the temperature remains stable and uniform.

Relying on uncontrolled heat sources introduces the risk of "hot spots" that can scorch and damage portions of the honey, even if the average temperature seems safe.

How to Apply This to Your Process

Your approach should be guided by your end goal for the honey.

- If your primary focus is preserving maximum enzymatic activity and raw quality: Operate at the lower end of the spectrum, precisely at 35°C, and do not deviate.

- If your primary focus is balancing efficiency with high quality: You may operate within the 35-40°C range, but view 40°C as a strict ceiling that should never be exceeded.

- If you are concerned about any potential damage to your product: Recognize that heating above 40°C introduces unacceptable risk, and heating above 50°C will cause rapid degradation.

Ultimately, careful temperature management is the key to protecting the natural integrity of your honey.

Summary Table:

| Temperature Range | Impact on Honey Quality | Recommendation |

|---|---|---|

| 35–40°C (95–104°F) | Optimal Quality Preservation | Ideal range for gentle moisture removal. Protects delicate enzymes and aromas. |

| > 40°C (104°F) | Quality Degradation Begins | Avoid. Accelerates damage to sensitive compounds. |

| > 50°C (122°F) | Severe Quality Loss | Highly destructive. Rapidly degrades nutritional and aromatic value. |

Protect Your Honey's Quality with the Right Equipment

Achieving the precise 35°C temperature is critical for commercial beekeepers and distributors who value quality. HONESTBEE supplies professional beekeeping equipment designed for exact temperature control, ensuring your honey retains its natural enzymes, flavor, and market value.

Let us help you select the right dryer for your operation. Contact our experts today to discuss your commercial honey processing needs.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- How does micro-climate control equipment affect honey quality? Essential Guide for Commercial Honey Storage

- What is the issue with high moisture content in honey? Prevent Fermentation & Protect Your Honey's Value

- What is the primary role of an automated temperature and humidity control honey drying cabinet? Ensure Honey Quality.

- What functions do high-precision filtering and moisture control equipment serve in honey refining? Ensure Pure Quality

- What is the function of a portable hygrometer in honey collection? Protect Your Harvest from Excess Moisture

- What technical advantages does a heat pump dryer provide in honey moisture regulation? Preserve Quality & Enzymes

- Why is Postharvest Drying Equipment critical in the stingless bee honey supply chain? Prevent Spoilage & Boost Quality

- Why is professional moisture reduction equipment necessary for Trigona honey? Protect Your Stingless Bee Honey Quality