At its core, a honey filler is designed for versatility. You can fill a wide range of standard containers, including glass jars, plastic bottles, flexible pouches, and specialty containers like honey bears. The key is understanding that the specific container you choose will dictate the necessary adjustments to the filling machine, such as the nozzle type and filling speed, to ensure an accurate, clean, and efficient process.

The question isn't just what container you can fill, but how the design of that container interacts with the type of filling machine you use. Matching the filler mechanism to your container's material, shape, and opening is the true key to a successful packaging operation.

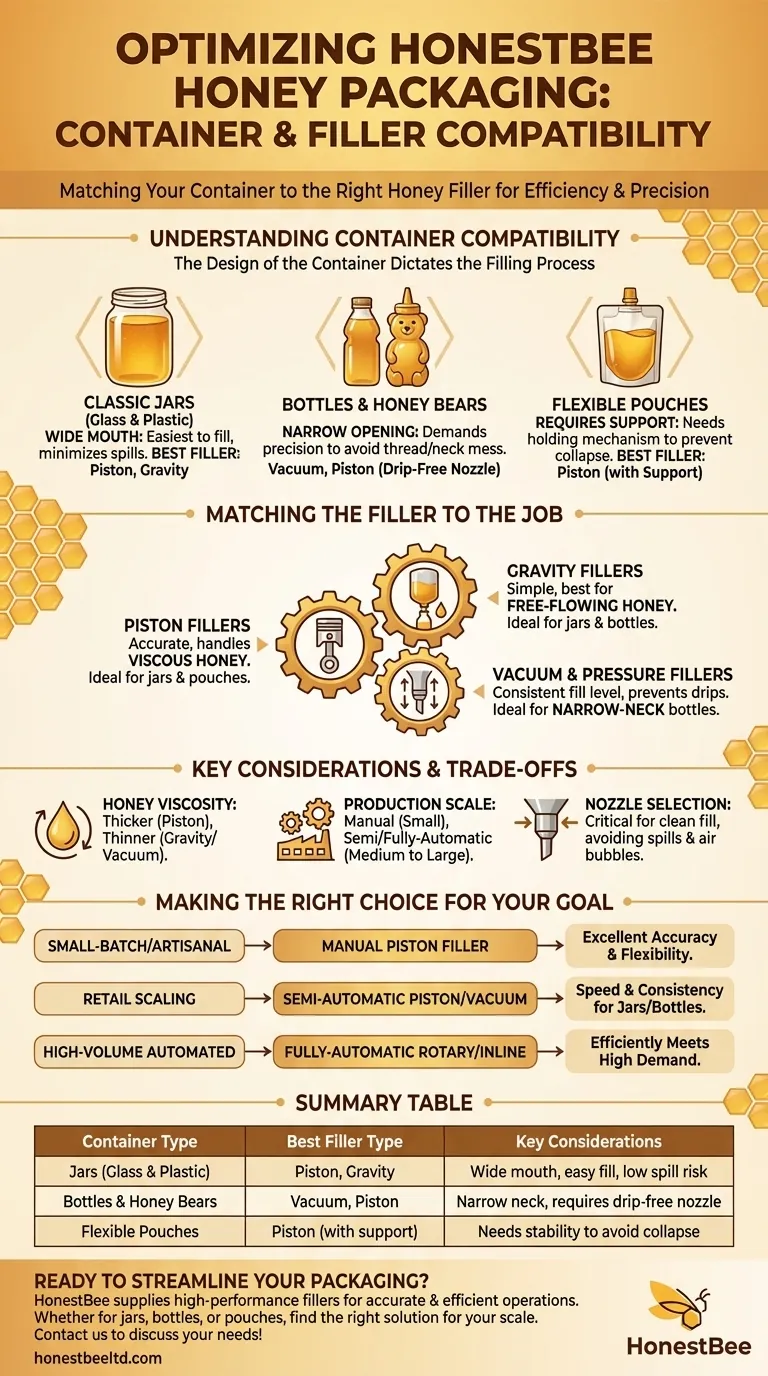

Understanding Container Compatibility

The primary goal of any filling system is to dispense a precise amount of honey cleanly and consistently. The container is a critical variable in this equation.

Classic Glass and Plastic Jars

Jars are the most common and straightforward container to fill due to their wide mouths. This design minimizes the risk of spills and accommodates a variety of nozzle types.

Most filler types, from simple manual piston fillers to complex fully-automatic rotary systems, handle standard jars with ease. The wide opening provides a generous target for the honey stream.

Bottles and "Honey Bears"

Bottles, especially those with narrower openings like squeeze bottles or "honey bears," demand more precision. The challenge is to fill the container without getting honey on the threads or neck.

For these containers, you often need specialized nozzles that can enter the neck of the bottle. Vacuum fillers or piston fillers with drip-free nozzles are particularly effective, as they offer precise control over the start and stop of the honey flow.

Flexible Pouches

Stand-up pouches are a growing packaging trend, but they require specific handling. Their flexible nature means they need support during the filling process to prevent collapsing or tipping over.

Fillers for pouches often include a mechanism to hold the pouch open and stable. The filling speed and pressure must be carefully calibrated to avoid overfilling or stressing the pouch seams.

Matching the Filler to the Job

The type of filling machine is just as important as the container it's filling. Each mechanism has strengths suited for different scales of production and types of honey.

Piston Fillers

A piston filler uses a cylinder to pull in and then push out a precise volume of honey. This method is extremely accurate and is ideal for viscous, thick honey. It works well with almost any container type, especially wide-mouth jars.

Gravity Fillers

A gravity filler holds honey in a tank above the containers and uses the force of gravity to fill them. This method is simpler and works best for less viscous, more free-flowing honey. It is typically used for bottles and jars.

Vacuum and Pressure Fillers

These systems use pressure differences to move honey. A vacuum filler is excellent for ensuring a consistent fill level in rigid containers and preventing drips, making it ideal for narrow-necked bottles.

Key Considerations and Trade-offs

Choosing the right combination of container and filler involves balancing cost, speed, and product characteristics.

The Impact of Honey Viscosity

Thicker, creamed honey behaves very differently than thin, liquid honey. A thick product requires the power of a piston filler, while a gravity filler might be too slow or unable to handle it at all.

Production Scale Matters

A manual filler is perfect for a small-scale or hobbyist operation filling a few hundred jars. For medium to large industries, semi-automatic or fully-automatic systems are necessary to achieve the required speed and consistency for thousands of containers.

The Nozzle is Critical

Never underestimate the importance of the nozzle. A nozzle that is too large for the container opening will cause spills, while one that is too small can slow down production and introduce air bubbles. Proper nozzle selection is essential for a clean fill.

Making the Right Choice for Your Goal

Your ideal setup depends entirely on your operational needs and the product you are selling.

- If your primary focus is small-batch, artisanal production: A manual piston filler offers excellent accuracy and flexibility for filling standard glass jars with minimal investment.

- If your primary focus is scaling up production for retail: A semi-automatic piston or vacuum filler provides the speed and consistency needed for bottles and jars while retaining some operational flexibility.

- If your primary focus is high-volume, automated packaging: A fully-automatic rotary or inline system designed for your specific container (jars, bottles, or pouches) is the only way to meet demand efficiently.

Ultimately, selecting the right equipment empowers you to package your product accurately and professionally, no matter the scale.

Summary Table:

| Container Type | Best Filler Type | Key Considerations |

|---|---|---|

| Glass & Plastic Jars | Piston, Gravity | Wide mouth, easy to fill, minimal spill risk |

| Bottles & Honey Bears | Vacuum, Piston | Narrow neck, requires drip-free nozzle for precision |

| Flexible Pouches | Piston (with support) | Needs stability during filling to avoid collapse |

Ready to streamline your honey packaging process? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-performance honey fillers designed for accuracy and efficiency. Whether you're filling jars, bottles, or pouches, our wholesale-focused solutions ensure you get the right equipment for your scale and container type. Contact us today to discuss your needs and discover how we can boost your packaging productivity!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- How does an automated filling machine contribute to the commercialization of Trigona sp. honey? Scale Your Production

- What types of honey stick machines are available based on the style of the stick pack? Choose the Perfect Packaging Format

- What is a manual honey filler and where is it used? The Essential Guide for Small-Scale Honey Bottling

- What role do industrial honey filling machines play in competitiveness? Boost Scalability & Brand Value

- How do industrial honey filling machines ensure monofloral quality? Protect Flavor and Purity with Advanced Tech

- Why is high-precision honey-filling equipment essential? Ensure Consistency for Fir and Chestnut Honey

- Why exclude container weight in honey filling? Master Net Mass Accuracy with Industrial Machinery

- What types of filling mechanisms are used in honey filling machines? Find the Best Tech for Your Viscosity