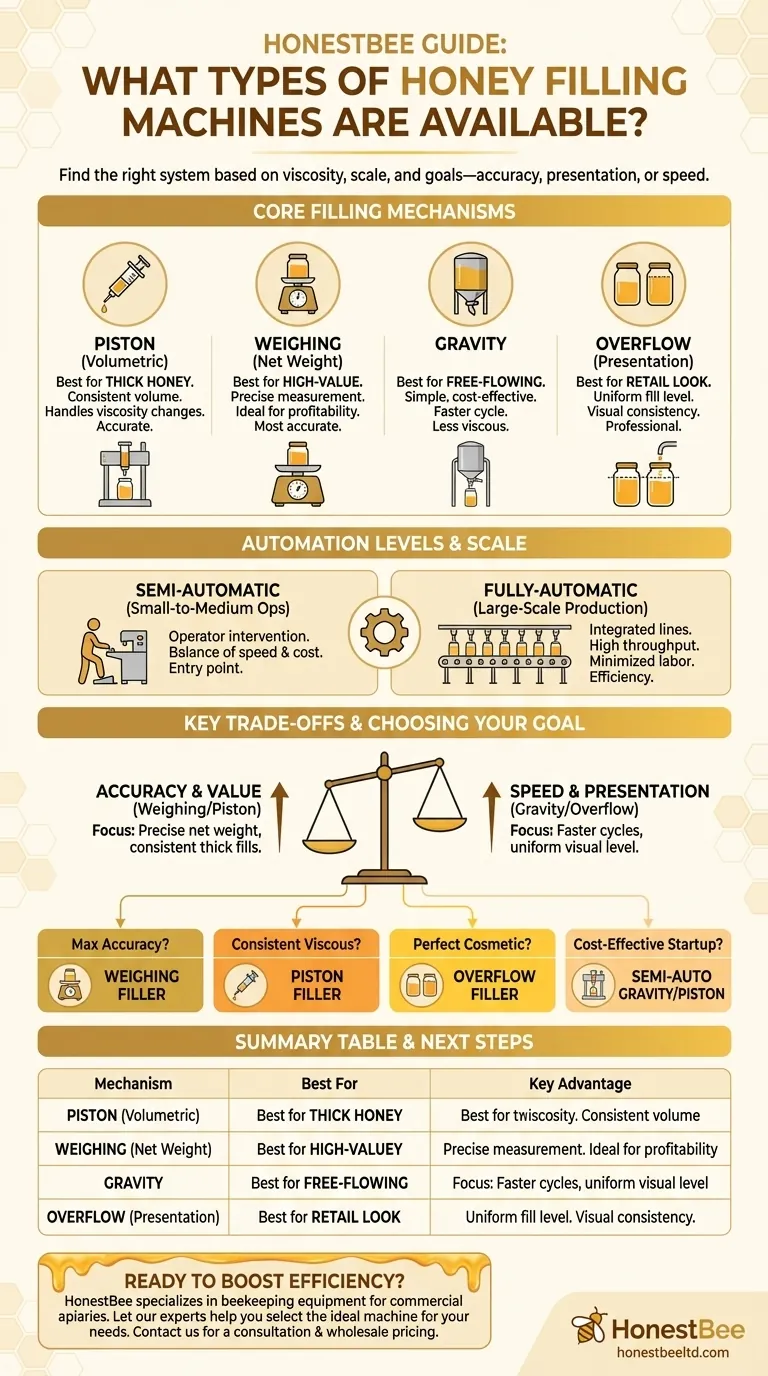

The primary types of honey filling machines are categorized by their filling mechanism: Piston (Volumetric), Weighing, Gravity, and Overflow fillers. These types can be further classified by their level of automation—from semi-automatic models for smaller operations to fully-automatic systems for large-scale production.

The best honey filling machine is not a single model, but a system whose technology directly matches your honey's viscosity, your production scale, and your primary goal, whether that is absolute accuracy, presentation, or speed.

Understanding the Core Filling Mechanisms

The technology used to dispense the honey is the most critical factor in your decision. Each mechanism is suited for different product consistencies and operational priorities.

Piston Fillers (Volumetric)

A piston filler is the most common choice for honey due to its versatility and accuracy. It operates like a large syringe, pulling a precise volume of honey into a cylinder and then dispensing it into the container.

This method is highly effective for thick, viscous liquids, ensuring a consistent amount of product is dispensed every time, regardless of temperature or minor viscosity changes.

Weighing Fillers (Net Weight)

A weighing filler uses a scale to dispense honey until a pre-set target weight is reached. This is the most accurate method available.

It is ideal for high-value honey products where precise measurement is critical for profitability and compliance. It also eliminates inaccuracies caused by inconsistent container weights.

Gravity Fillers

A gravity filler holds the honey in a tank above the filling nozzles. It relies on gravity to fill the containers placed below.

This is a simpler, more cost-effective mechanism best suited for less viscous, free-flowing honey. While fast, its accuracy can be affected by changes in honey temperature and viscosity.

Overflow Fillers

An overflow filler is designed for presentation. It fills each container to the exact same visual level, regardless of minor inconsistencies in container volume.

This is achieved by overfilling the container slightly and then drawing the excess product back into the supply tank. This method is perfect for producers using clear glass jars who want a uniform, professional look on the shelf.

Automation Level: The Scale of Your Operation

Beyond the core mechanism, the level of automation determines the machine's throughput and labor requirements.

Semi-Automatic Machines

These machines require an operator to place containers under the fill heads and initiate the filling cycle, often with a foot pedal.

They are an excellent entry point for small-to-medium operations, artisanal producers, and businesses with varied container sizes, offering a balance between speed and cost.

Fully-Automatic Machines

Fully-automatic machines integrate into a production line with conveyors. They handle container feeding, filling, and movement without operator intervention.

These systems are built for high-speed, large-scale commercial production where efficiency and minimizing labor costs are paramount.

Understanding the Trade-offs

Choosing the right machine involves balancing competing priorities. There is no single "best" solution, only the best fit for your specific needs.

Accuracy vs. Speed

Weighing and piston fillers offer the highest accuracy but may have a slower cycle time per nozzle. Gravity and overflow fillers are typically faster but may sacrifice pinpoint volumetric or weight accuracy.

Viscosity is Crucial

The thickness of your honey is a non-negotiable factor. Forcing thick, high-viscosity honey through a gravity filler will result in slow, inaccurate fills. A piston or pump filler is essential for these products.

Cost and Complexity

Simpler systems like semi-automatic gravity fillers have the lowest initial cost and are easier to maintain. Fully-automatic, multi-head weighing systems represent a significant capital investment and require more technical expertise to operate.

Container Type Matters

While most fillers handle standard jars, specialized packaging requires specific machinery. Honey sticks and sachets are typically filled using machines that incorporate a volumetric filler into a form-fill-seal process.

Making the Right Choice for Your Goal

Select your machine by first defining your most important operational priority.

- If your primary focus is maximum accuracy and product value: A weighing filler is the best choice to ensure precise net weight in every container.

- If your primary focus is consistent fills with viscous honey: A piston (volumetric) filler provides the power and precision needed for thick products.

- If your primary focus is a perfect cosmetic fill level for retail: An overflow filler will give your products a uniform and professional appearance.

- If your primary focus is a cost-effective solution for a startup: A semi-automatic gravity or single-piston filler offers the best balance of performance and initial investment.

Choosing the right equipment is a direct investment in your product's quality and your operation's efficiency.

Summary Table:

| Filling Mechanism | Best For | Key Advantage |

|---|---|---|

| Piston Filler | Thick, viscous honey | Consistent volume, handles viscosity changes |

| Weighing Filler | High-value honey, maximum accuracy | Precise net weight, ideal for profitability |

| Gravity Filler | Free-flowing honey, cost-effectiveness | Simple operation, faster cycle times |

| Overflow Filler | Retail presentation, glass jars | Uniform fill level for a professional look |

Ready to boost your honey production efficiency?

At HONESTBEE, we specialize in supplying the right beekeeping equipment to commercial apiaries and distributors. Let our experts help you select the ideal honey filling machine—whether it's a high-accuracy piston filler for thick honey or a high-speed automatic system for large-scale production.

Contact our team today for a personalized consultation and wholesale pricing on reliable, performance-driven filling solutions.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What is the importance of honey filling machines? Scale Your Production and Ensure Product Integrity

- What value do automatic honey-filling machines offer? Scaling Commercial Honey Production with Precision

- Why is a specialized honey filling machine necessary? Preserve Premium Abies Alba Honey Quality & Aroma

- Why is it necessary for commercial apiaries to utilize automated honey filling machines? Scale Your Production Safely

- Why is high-precision honey filling and packaging equipment critical in the industrial honey export process? Scale Now

- What is the importance of using high-precision filling machines in honey bottling? Secure Purity & Profits

- Why should ease of cleaning and maintenance be considered when selecting a honey packaging machine? Ensure Purity & ROI

- What is the operational process of a stick pack packaging machine? Efficient Honey Sachet Production Guide