At their core, volumetric filling machines are designed for remarkable versatility, capable of handling a vast spectrum of products. They excel at dispensing anything from thin, water-like liquids such as beverages and syrups to thick, viscous products like lotions, creams, sauces, and pastes. This includes pharmaceuticals, food items, personal care products, and industrial goods like paint.

The critical insight is not simply what products can be filled, but understanding that the product's specific characteristics—especially its viscosity—will determine which type of volumetric filler is the correct tool for the job.

The Principle Behind Volumetric Versatility

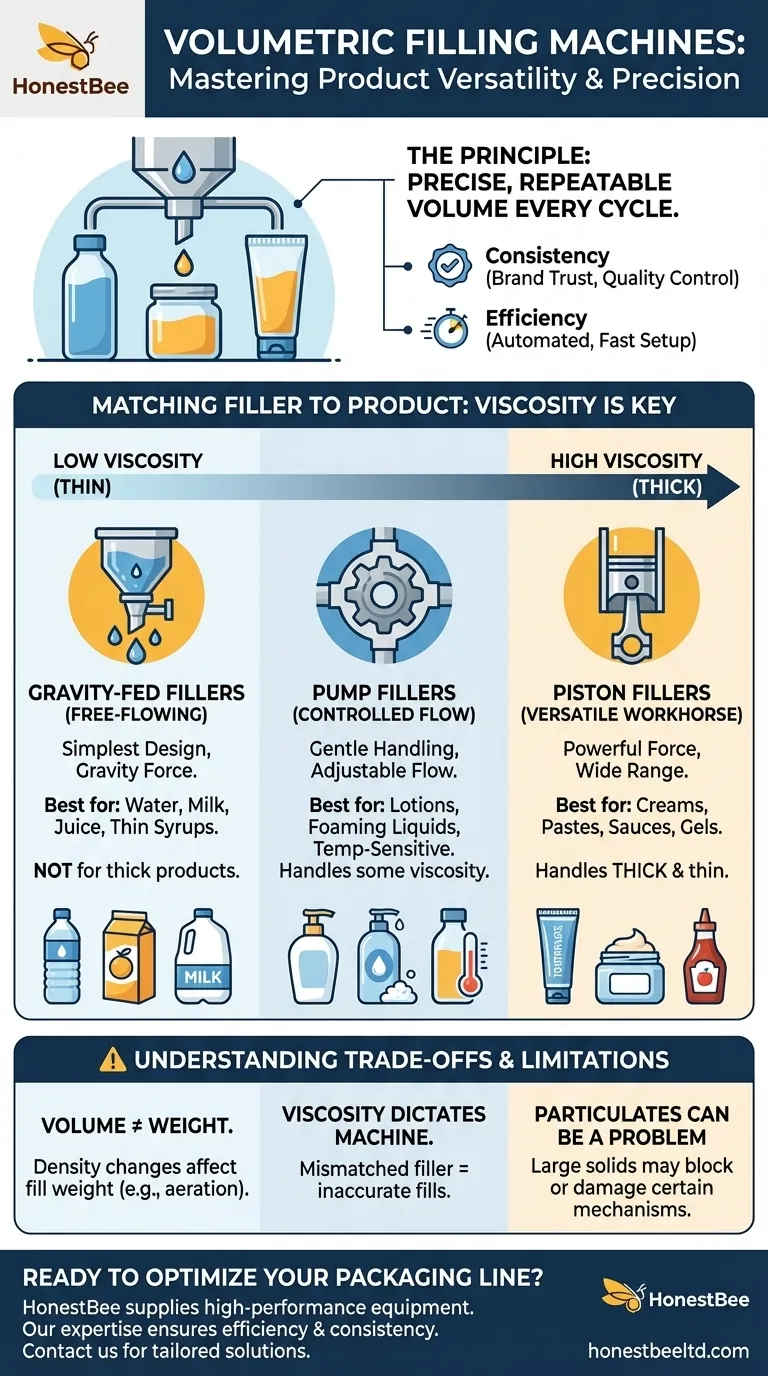

Volumetric fillers operate on a simple, powerful principle: they dispense a precise, repeatable volume of product with each cycle. This makes them exceptionally efficient and consistent.

Consistency is Key

By dispensing the same volume every time, these machines ensure uniform packaging. This is crucial for brand trust and quality control, guaranteeing that every container, from a yogurt cup to a toothpaste tube, meets the same standard.

Driving Efficiency

Automating the filling process with a volumetric system dramatically increases productivity and reduces the labor costs associated with manual filling. Their straightforward operation allows for quick setup and changeovers between different products or container sizes.

Handling Special Conditions

Beyond standard liquids and pastes, specialized volumetric systems are engineered to handle more challenging products. This includes liquids that need to be heated or cooled during the filling process or those that are prone to foaming, which requires careful dispensing to prevent air pockets.

Matching the Filler to the Product

The term "volumetric filler" is a broad category. The machine's internal mechanism is what truly defines its capabilities. The three primary types each serve a different purpose.

Piston Fillers: The Versatile Workhorse

Piston fillers are the most common and versatile type. A piston moves within a cylinder to pull in and then push out a precise volume of product.

This mechanism provides enough force to handle a very wide range of viscosities, from thin juices to extremely thick pastes like tomato concentrate or putty. This makes them a go-to choice for businesses with diverse product lines.

Pump Fillers: For Controlled Flow

Pump filling machines use a pump (such as a lobe, gear, or progressive cavity pump) to move the product. The volume is determined by the pump's rotation or the time it operates.

These systems are excellent for products that require a specific flow rate or gentle handling. They are also easily adapted for products that are temperature-sensitive or foam easily, as the pump speed can be precisely controlled.

Gravity-Fed Fillers: For Free-Flowing Liquids

Gravity fillers are the simplest design. They use the force of gravity to fill containers from a hopper located above the filling nozzles.

Because they rely on gravity, these machines are only suitable for low-viscosity, free-flowing liquids like water, milk, coffee creamers, or thin syrups. They are highly efficient and cost-effective for the right application but cannot handle thicker products.

Understanding the Trade-offs

While highly capable, volumetric fillers are not a universal solution. Understanding their limitations is key to making an informed decision.

Volume is Not Always Weight

The primary limitation is inherent in the name: they fill by volume. If your product's density changes with temperature or aeration, the final weight of each container can vary even if the volume is identical. For products sold by weight, a net-weight filler may be a better choice.

Viscosity Dictates the Machine

You cannot use a simple gravity filler for a thick cream. The product is too viscous to flow properly, resulting in inaccurate or incomplete fills. Matching the machine type (piston, pump, or gravity) to your product's viscosity is non-negotiable.

Particulates Can Be a Problem

Products with large, solid particulates—like a chunky salsa or a fruit preserve—can pose a challenge for some volumetric fillers. The tight tolerances in piston cylinders or the design of certain nozzles can damage the particulates or cause blockages.

How to Choose the Right Volumetric System

Your product's physical properties are the ultimate guide to selecting the right equipment.

- If your primary focus is free-flowing, low-viscosity liquids: A gravity-fed filler offers an excellent combination of speed, simplicity, and cost-effectiveness.

- If your primary focus is thick pastes, creams, or gels: A piston filler provides the power and precision required to accurately dispense high-viscosity products.

- If your primary focus is handling a wide variety of product types: A versatile piston filler is the most logical starting point for your evaluation.

- If your primary focus is a sensitive product that foams or requires temperature control: A specialized pump filler will give you the necessary control over the filling process.

By first analyzing your product, you can confidently select a volumetric system that guarantees accuracy and efficiency.

Summary Table:

| Product Type | Ideal Filler Type | Key Characteristics |

|---|---|---|

| Thin Liquids (water, milk, juice) | Gravity Filler | Free-flowing, low viscosity |

| Viscous Products (creams, pastes, sauces) | Piston Filler | Thick, requires dispensing force |

| Sensitive/Foaming Liquids (pharmaceuticals, lotions) | Pump Filler | Requires gentle, controlled flow |

Ready to find the perfect volumetric filling machine for your product line? HONESTBEE supplies high-performance beekeeping supplies and equipment to commercial apiaries and distributors. Our expertise in durable, precise equipment can help you streamline your packaging process for maximum efficiency and consistency. Contact our team today to discuss your specific needs and get a tailored solution!

Visual Guide

Related Products

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Automated Rotary Bottle Unscrambler for Honey Production Line

- HONESTBEE 24 Head Rotary Bottle Washing Machine

People Also Ask

- Why are temperature-controlled hopper systems necessary for honey filling? Prevent Blockage & Ensure Dosage Accuracy

- What is the value of automated honey filling machines for commercial apiaries? Maximize Peak Harvest Profitability

- How does a weighing filling machine operate? Achieve Precise, Consistent Product Filling

- How does the use of standardized honey-filling machines improve distribution efficiency? 5 Key Benefits for Scale

- How do honey storage and filling machines boost market value? Elevate Your Product to Premium Retail Standards

- What role do professional automated filling and packaging machines play in honey processing? Boost Efficiency & Value

- How does honey filling machinery contribute to the industrialization of honey processing? Scaling Global Production

- Why is the automated honey filling machine considered a core component? Boost Your Commercial Honey Processing Efficiency