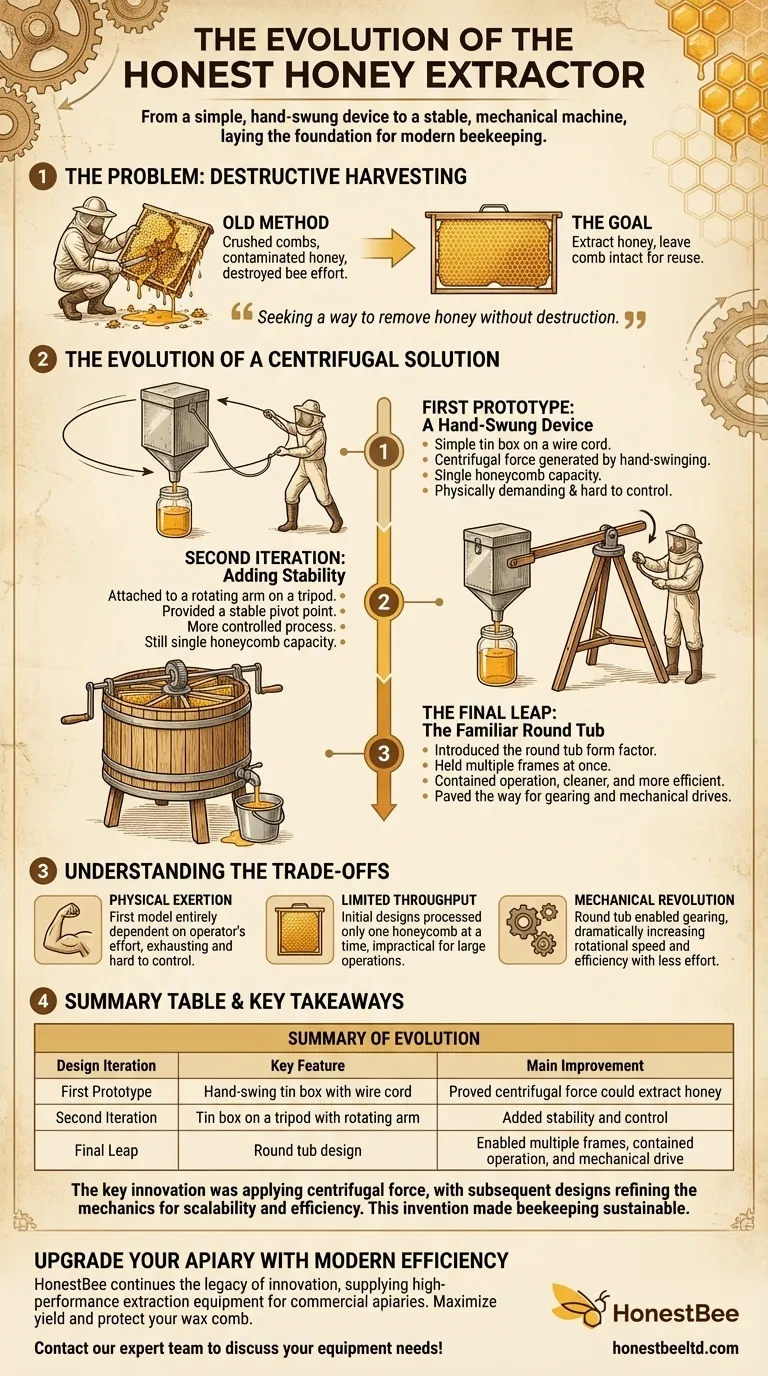

The very first honey extractor was a remarkably simple device, consisting of a tin box for holding a honeycomb, attached to a wire cord. This crude machine was swung by hand to generate centrifugal force, with a funnel and glass at the bottom to catch the extracted honey.

The evolution of the honey extractor demonstrates a classic engineering progression: from a simple, manually-operated proof-of-concept to a stable, mechanically-driven machine that laid the foundation for all modern designs.

The Problem: Extracting Honey Without Destruction

The Old Method

Before the invention of the extractor, harvesting honey was a destructive process. Beekeepers had to crush the entire honeycomb to press the honey out.

The Inefficiency

This method not only destroyed the intricate wax comb, which bees spend enormous energy building, but it also resulted in honey contaminated with wax and other debris. The goal was to find a way to remove the honey while leaving the comb intact for the bees to reuse.

The Evolution of a Centrifugal Solution

The First Prototype: A Hand-Swung Device

The initial design was a direct application of centrifugal force. It was a simple tin box attached to a wire cord.

A single honeycomb was placed inside the box, which was then swung in a large circle by hand. The outward force slung the honey from the cells.

A funnel was attached to the bottom of the box, directing the flowing honey into a glass jar.

The Second Iteration: Adding Stability

The next version addressed the unwieldy nature of the hand-swung model. The core design of the tin box and funnel remained the same.

However, it was now attached to a rotating arm fixed at the top of a tripod. This provided a stable pivot point, making the process more controlled and less physically demanding than swinging a cord.

The Final Leap: The Familiar Round Tub

The third and final version of the initial design introduced the form factor we recognize today. This model used a familiar round tub.

This design was a significant improvement, as it could likely hold multiple frames at once and keep the entire operation contained, which was cleaner and far more efficient. It established the foundational architecture for the modern radial and tangential extractors used worldwide.

Understanding the Trade-offs of Early Designs

Physical Exertion and Control

The first hand-swung model was entirely dependent on the operator's physical ability. It would have been exhausting to operate and difficult to control the speed, potentially leading to damaged combs.

Limited Throughput

The first two designs could only process one honeycomb at a time. This made them functional for a hobbyist but impractical for any larger-scale honey harvesting operation.

The Introduction of Mechanics

While the tripod added stability, the introduction of the round tub was the true turning point. This design paved the way for gearing and hand cranks, allowing for much higher rotational speeds with far less effort, dramatically increasing the efficiency of honey extraction.

Key Takeaways from the Extractor's Evolution

These early designs show a clear and logical progression in solving a core problem for beekeepers.

- If your primary focus is historical context: The key innovation was applying centrifugal force to solve the problem, with subsequent designs focused purely on refining the mechanics of that application.

- If your primary focus is engineering principles: The extractor's development perfectly illustrates the move from a simple proof-of-concept to a stable, scalable, and mechanically efficient machine.

This invention fundamentally changed beekeeping, enabling honey to be harvested sustainably while preserving the vital wax comb for the colony.

Summary Table:

| Design Iteration | Key Feature | Main Improvement |

|---|---|---|

| First Prototype | Hand-swing tin box with wire cord | Proved centrifugal force could extract honey |

| Second Iteration | Tin box on a tripod with rotating arm | Added stability and control |

| Final Leap | Round tub design | Enabled multiple frames, contained operation, and mechanical drive |

Upgrade Your Apiary with Modern Efficiency

The invention of the honey extractor transformed beekeeping from a destructive process to a sustainable practice. Today, HONESTBEE continues this legacy of innovation by supplying commercial apiaries and beekeeping equipment distributors with high-performance, durable extraction equipment and supplies. Our wholesale-focused operations ensure you get the reliable tools you need to maximize your honey yield and protect your valuable wax comb.

Ready to modernize your honey harvest? Contact our expert team today to discuss your equipment needs and discover how HONESTBEE can support your business's growth.

Visual Guide

Related Products

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- How do beekeepers harvest honey from the honey super? A Step-by-Step Guide to Efficient Extraction

- What is a tangential extractor and how does it work? A Complete Guide for Hobbyist Beekeepers

- What equipment do you need to process honey? A Complete Guide for Every Scale of Operation

- How to get honey out of a frame? Choose Between Crush & Strain or Centrifugal Extraction

- What are the main components of a honey extractor? A Guide to Efficient Honey Harvesting