For medium to large-scale honey processing, the definitive answer is an electric, radial-style honey extractor. These machines are engineered specifically for the higher capacity, speed, and efficiency required in commercial or serious sideline operations. Unlike manual models that become a physical bottleneck, electric extractors automate the most labor-intensive step, directly increasing your potential output.

The core issue for a growing operation is not just extracting honey, but optimizing the entire workflow. Shifting from a manual or tangential extractor to an electric radial model is the single most important upgrade to reduce labor, increase throughput, and improve overall profitability.

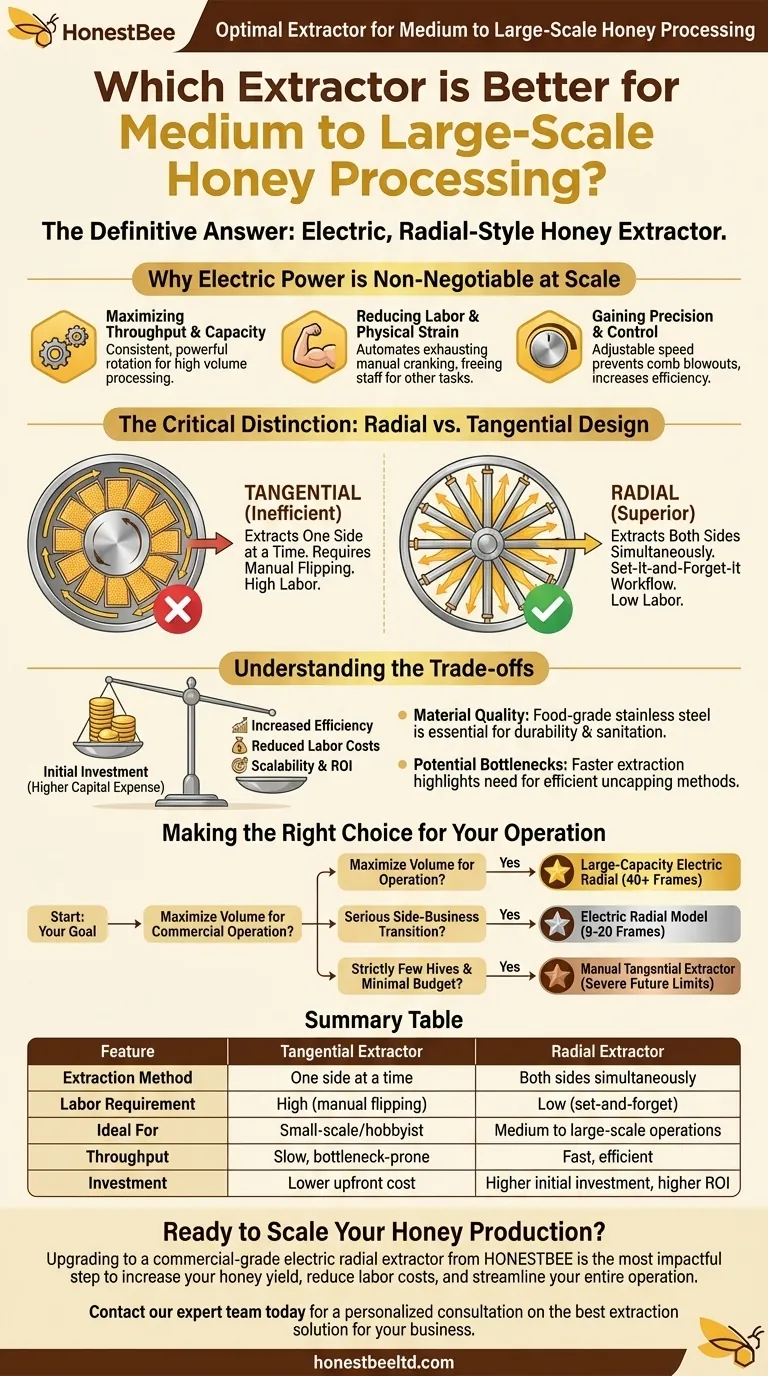

Why Electric Power is Non-Negotiable at Scale

Moving beyond a small hobbyist setup means treating honey extraction as a production process. Electric power is the engine that drives this efficiency.

Maximizing Throughput and Capacity

An electric motor provides consistent and powerful rotation that a human arm simply cannot match over long periods. This allows you to process a higher volume of frames in a fraction of the time, clearing your backlog from the apiary to the bottling tank much faster.

Reducing Labor and Physical Strain

Manually cranking an extractor loaded with dozens of heavy frames is physically exhausting. An electric model automates this work, freeing you or your staff to focus on other critical tasks like uncapping the next batch of frames or managing the extracted honey.

Gaining Precision and Control

Professional electric extractors feature adjustable speed controls. This is crucial for preventing "blowouts," where the force of extraction destroys delicate new comb. You can start slowly to extract a portion of the honey, lightening the frame before ramping up to full speed.

The Critical Distinction: Radial vs. Tangential Design

The choice of an electric motor is only half the equation. The internal design of the extractor basket is arguably even more important for efficiency.

The Inefficiency of Tangential Extractors

Tangential extractors hold frames with one side facing the outer wall, like laundry in a spin dryer. This means they only extract honey from one side of the frame at a time. You must stop the machine, manually flip every single frame, and restart the process. For a large harvest, this adds hours of repetitive labor.

The Superiority of Radial Extractors

Radial extractors position frames with the top bar facing outwards, like spokes on a wheel. As the machine spins, centrifugal force pulls honey from both sides of the comb simultaneously. You load the frames once, run the machine, and they come out empty. This "set it and forget it" workflow is the standard for any serious commercial operation.

Understanding the Trade-offs

Investing in a commercial-grade extractor requires careful consideration of the costs and features that truly matter.

The Initial Investment

There is no avoiding it: a large, stainless steel, electric radial extractor is a significant capital expense. However, it should be viewed as an investment. The return comes from dramatically increased efficiency, reduced labor costs, and the ability to scale your operation without hitting a processing wall.

Material and Build Quality

For any food processing equipment, food-grade stainless steel is the only acceptable material. It is durable, rust-resistant, and easy to sanitize, protecting the quality of your honey and preventing contamination. A heavy-duty, stable base is also critical to manage the immense forces of a fully loaded machine spinning at high speed.

Potential Bottlenecks

An efficient extractor will quickly highlight other bottlenecks in your process. Your ability to uncap frames will become the new limiting factor. A powerful extractor must be matched with an efficient uncapping method, such as a hot knife, flail uncapper, or automated uncapping machine, to keep it fed.

Making the Right Choice for Your Operation

Your decision should be guided by your operational goals and desired scale.

- If your primary focus is maximizing volume for a commercial operation: A large-capacity (40+ frame) electric radial extractor made from food-grade stainless steel is the only viable long-term choice.

- If your primary focus is transitioning from hobbyist to a serious side-business: Prioritize an electric radial model, even if it's a smaller version (9-20 frames). The labor savings will immediately justify the cost and provide room to grow.

- If your primary focus is strictly managing a few hives with minimal budget: A manual tangential extractor will work, but you must accept that it will severely limit your ability to expand efficiently in the future.

Choosing the right extractor transforms honey processing from a laborious chore into a streamlined and profitable part of your business.

Summary Table:

| Feature | Tangential Extractor | Radial Extractor |

|---|---|---|

| Extraction Method | One side at a time | Both sides simultaneously |

| Labor Requirement | High (manual flipping) | Low (set-and-forget) |

| Ideal For | Small-scale/hobbyist | Medium to large-scale operations |

| Throughput | Slow, bottleneck-prone | Fast, efficient |

| Investment | Lower upfront cost | Higher initial investment, higher ROI |

Ready to Scale Your Honey Production?

Upgrading to a commercial-grade electric radial extractor from HONESTBEE is the most impactful step to increase your honey yield, reduce labor costs, and streamline your entire operation. We supply durable, food-grade stainless steel extractors and a full range of beekeeping equipment designed for the demands of commercial apiaries and distributors.

Contact our expert team today for a personalized consultation on the best extraction solution for your business.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- Commercial 48-Frame Stainless Steel Honey Extractor

People Also Ask

- How should an electric honey extractor be maintained and cared for? Protect Your Investment and Honey Purity

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- What are some safety tips for using electric honey extractors? Ensure a Smooth, Hazard-Free Harvest

- What is the difference between manual and electric honey extractors? Choose the Right Tool for Your Hive Count

- What is a machine used to remove honey from frames? The Complete Guide to Honey Extractors