For a growing beekeeping operation, a honey press represents a fundamental shift from manual labor to industrial-scale throughput. Its indispensability for larger apiaries lies in its ability to crush enormous batches of honeycomb, increase the volume processed per run, and hold significant amounts of honey, creating a continuous workflow that manual methods cannot sustain.

The core value of a honey press at scale is not just about extracting honey. It's about transforming a stop-and-start manual task into a continuous, high-volume process that drastically reduces labor and downtime.

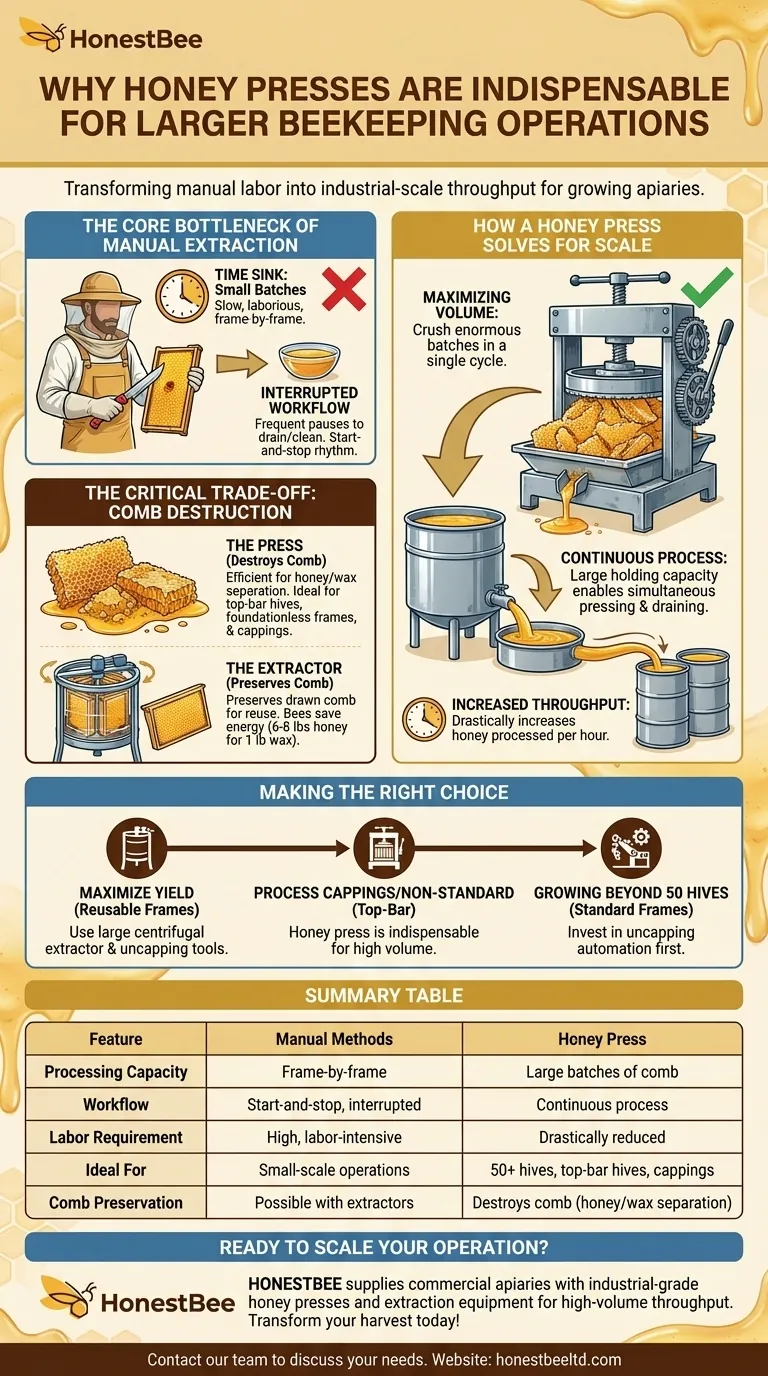

The Core Bottleneck of Manual Extraction

The Time Sink of Small Batches

In a small operation, using an uncapping fork or a hot knife is manageable. However, these manual methods become a significant bottleneck when dealing with dozens or hundreds of frames.

Each frame requires individual attention, turning the extraction process into a slow, laborious task that limits how much honey can be processed in a day.

The Problem of Interrupted Workflow

Smaller setups also require frequent pauses. You must constantly stop to drain small amounts of honey or clean equipment between batches.

This start-and-stop rhythm is inherently inefficient and prevents the kind of streamlined operation necessary for a large-scale apiary.

How a Honey Press Solves for Scale

Maximizing Volume Per Run

A honey press is built for bulk. Its primary design advantage is the capacity to crush large quantities of honeycomb in a single cycle.

This immediately removes the frame-by-frame limitation of manual uncapping, allowing you to process the equivalent of many hives' worth of comb at once.

Enabling a Continuous Process

Larger honey presses are designed with significant holding capacity for the extracted honey.

This feature is critical, as it allows you to continue pressing new batches of comb while the honey from previous runs is still draining and being strained. The workflow never has to stop.

Increasing Overall Throughput

By combining high-volume capacity with a continuous workflow, a honey press drastically increases the total amount of honey you can process per hour.

This efficiency is the key reason they become essential for any beekeeper managing a large number of hives, often cited as being over 50.

Understanding the Critical Trade-off: Comb Destruction

The Press vs. The Extractor

It is crucial to understand that a honey press destroys the honeycomb by crushing it. This process mixes honey and wax, which are then separated.

A centrifugal extractor, by contrast, removes honey while preserving the drawn-out comb on the frame. This is a fundamental difference in strategy.

The Energy Cost of Rebuilding Comb

Bees expend a tremendous amount of energy to produce wax and draw out comb. It is estimated bees consume 6-8 pounds of honey to produce just one pound of wax.

Reusing drawn comb gives the colony a massive head start, allowing them to focus on nectar collection and honey storage rather than rebuilding their hive infrastructure.

When a Press is the Right Tool

A press is the ideal choice for honey from top-bar hives, foundationless frames, or for processing the wax cappings that are sliced off frames before they go into an extractor.

In these cases, the comb was not going to be reused anyway, so crushing it is the most efficient method for separating the honey and wax.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on your hive type and long-term goals.

- If your primary focus is maximizing honey yield with reusable frames (e.g., Langstroth): Your path to scale involves efficient uncapping tools and a large centrifugal extractor, not a press.

- If your primary focus is processing honey from cappings or non-standard frames (e.g., top-bar hives): A honey press is the indispensable tool for achieving high-volume throughput.

- If your operation uses standard frames and is growing beyond 50 hives: Your first investment in automation should be for uncapping, as this is the most common bottleneck before extraction.

Ultimately, understanding whether your goal is to preserve comb or simply process honey and wax in bulk is the key to scaling your harvest successfully.

Summary Table:

| Feature | Manual Methods | Honey Press |

|---|---|---|

| Processing Capacity | Frame-by-frame | Large batches of comb |

| Workflow | Start-and-stop, interrupted | Continuous process |

| Labor Requirement | High, labor-intensive | Drastically reduced |

| Ideal For | Small-scale operations | 50+ hives, top-bar hives, cappings |

| Comb Preservation | Possible with extractors | Destroys comb (honey/wax separation) |

Ready to scale your beekeeping operation? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the industrial-grade honey presses and extraction equipment needed for high-volume throughput. Our wholesale-focused operations ensure you get the right equipment to transform your harvest from a manual task into a continuous, efficient process. Contact our team today to discuss your large-scale beekeeping equipment needs!

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Stainless Steel Honey Press Wax Press with Tank

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

People Also Ask

- What is the pressing method of honey? Preserve Flavor & Quality with Traditional Extraction

- How does the use of an industrial-grade honey press improve the hygiene quality of honey products? Elevate Safety

- How does a honey screw press operate to separate honey from wax? Boost Your Apiary Efficiency

- What is a Honey Press and what are its alternative names? Discover the Best Manual Extraction Methods

- For which type of beekeeping operations is this honey press most suitable? Efficient Solutions for High-Volume Apiaries

- What are the product advantages of honey pressing vs centrifugal extraction? Unlock Superior Artisanal Quality

- What factors should be considered when choosing between a honey press and an electric honey extractor?

- How is a fruit or honey press used to extract honey from comb? Master Cold-Pressed Honey for Maximum Purity