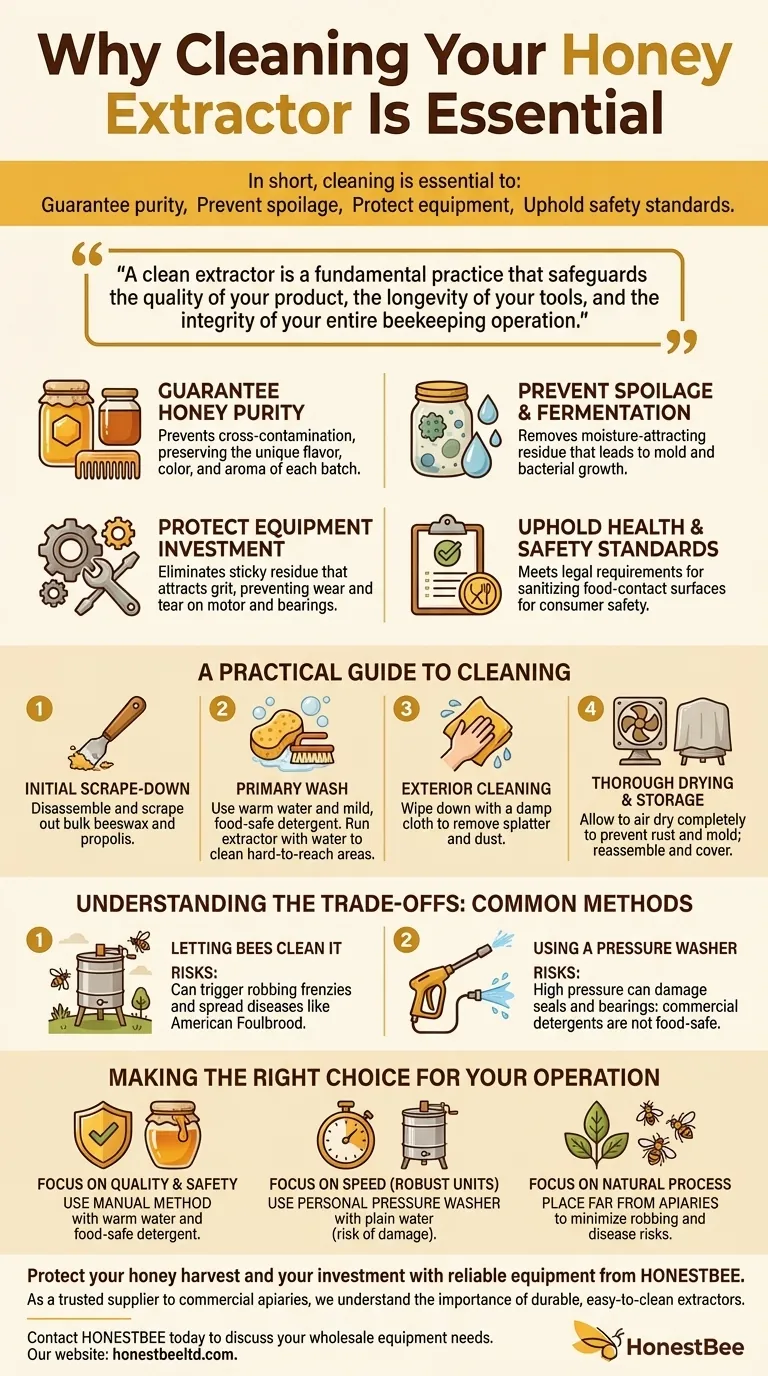

In short, cleaning your honey extractor is essential for four primary reasons. It guarantees the purity of each honey batch, prevents the fermentation and spoilage of leftover honey, protects your equipment from wear and tear, and ensures you meet health and safety standards, especially if you plan to sell your honey.

A clean extractor is not just about hygiene; it is a fundamental practice that safeguards the quality of your product, the longevity of your tools, and the integrity of your entire beekeeping operation.

The Core Reasons for Meticulous Cleaning

A honey extractor uses centrifugal force to pull honey from the comb. While efficient, this process inevitably leaves behind a residue of honey, wax, and propolis. Failing to clean this residue has significant consequences.

To Guarantee Honey Purity

Each honey flow has a unique flavor, color, and aroma based on the specific nectar sources the bees visited.

If you don't clean your extractor between harvests, crystallized honey, strong-flavored propolis, or dark wax from a previous batch can mix with and contaminate your new, lighter honey, compromising its purity and taste.

To Prevent Spoilage and Fermentation

Honey is hygroscopic, meaning it absorbs moisture from the air. A thin layer of honey left in an extractor can absorb enough moisture to ferment.

This can lead to mold and bacterial growth, which will spoil your next honey harvest and can be difficult to remove completely once established.

To Protect Your Equipment Investment

Sticky honey residue acts like a magnet for dust and debris, which can work its way into the extractor's bearings and moving parts.

This grit causes premature wear and tear on the motor and manual crank mechanisms, shortening the lifespan of one of your most expensive pieces of beekeeping equipment.

To Uphold Health and Safety Standards

For beekeepers who sell their honey, clean equipment is not optional—it's a legal requirement.

Health regulations demand that all food-contact surfaces be properly sanitized to prevent contamination and ensure consumer safety. A dirty extractor is a clear violation of these standards.

A Practical Guide to Cleaning Your Extractor

The most common and reliable cleaning method involves warm water and basic tools. It ensures a thorough, food-safe cleaning without risking damage to your equipment.

Step 1: The Initial Scrape-Down

First, disassemble any removable parts. Use a hive tool or a plastic spatula to scrape out the bulk of the remaining beeswax and propolis from the interior drum and frames.

Step 2: The Primary Wash

Use warm water to dissolve the remaining honey residue. A mild, food-safe detergent can help break down sticky films.

For stubborn spots, use a soft cloth or sponge. You can also add a few gallons of warm water, close the lid, and run the extractor for a minute to let the force of the water clean hard-to-reach areas. Drain the dirty water through the honey gate.

Step 3: Cleaning the Exterior

The outside of the extractor can be easily cleaned. Simply use a damp cloth, preferably with cold water, to wipe away any honey splatter, dust, or fingerprints.

Step 4: Thorough Drying and Storage

This is a critical final step. Allow the extractor and all its parts to air dry completely to prevent rust or mold.

Once fully dry, reassemble the unit and cover it to keep it clean and ready for your next harvest.

Understanding the Trade-offs: Common Cleaning Methods

While washing by hand is standard, beekeepers sometimes consider other methods. Each comes with significant trade-offs that you must understand.

Method 1: Letting Bees Clean It

Some beekeepers place the extractor outdoors to let the bees reclaim the leftover honey. While natural, this is risky.

It can trigger a "robbing frenzy," where bees from different hives (including neighboring apiaries) aggressively fight over the resources. This can lead to weak hives being destroyed and can rapidly spread diseases like American Foulbrood.

Method 2: Using a Pressure Washer

A pressure washer offers speed and power, quickly blasting away residue. However, this method can easily do more harm than good.

The high pressure can damage bearings, seals, and welded joints, particularly on less robust models. Furthermore, if you take it to a commercial car wash, the detergents used are not food-safe and can contaminate your equipment.

Making the Right Choice for Your Operation

Your cleaning method should align with your goals for safety, quality, and efficiency.

- If your primary focus is honey quality and food safety: Always use the manual method with warm water and a food-safe detergent, followed by thorough drying.

- If your primary focus is speed on a robust, stainless steel unit: A personal pressure washer used carefully with plain water can work, but you assume the risk of damaging seals or bearings.

- If your primary focus is a completely natural process: Allowing bees to clean the equipment is an option, but only if you can place it far from all apiaries to minimize the severe risk of robbing and disease transmission.

Properly cleaning and maintaining your equipment is a hallmark of a diligent and successful beekeeper.

Summary Table:

| Reason for Cleaning | Key Benefit |

|---|---|

| Guarantee Honey Purity | Prevents cross-contamination between batches, preserving unique flavor and color. |

| Prevent Spoilage | Stops fermentation and mold growth by removing moisture-attracting honey residue. |

| Protect Equipment | Extracts grit from moving parts, extending the lifespan of your investment. |

| Uphold Safety Standards | Meets legal requirements for beekeepers who sell their honey commercially. |

Protect your honey harvest and your investment with reliable equipment from HONESTBEE.

As a trusted supplier of beekeeping supplies and equipment to commercial apiaries and distributors, we understand the critical role that durable, easy-to-clean extractors play in your operation's success and compliance.

Let us help you equip your business with the right tools for superior honey quality and long-term efficiency.

Contact HONESTBEE today to discuss your wholesale equipment needs.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- Why are industrial-grade honey extractors essential for large-scale harvesting? Boost Your Forest Belt Honey Production

- Why is the use of centrifugal honey extractors critical for maintaining bee colony productivity? Maximize Your Yield

- Why is physical isolation of honey extractors necessary to manage Small Hive Beetles? Protect Your Honey Quality

- What is the importance of balancing honeycomb frames within a honey extractor? Ensure Stability and Protect Machinery

- What is an extractor in beekeeping? Unlock Sustainable Honey Harvesting

- What is a tangential extractor and how does it work? A Complete Guide for Hobbyist Beekeepers

- What technical advantages do specialized honey extractors offer? Boost Yield and Protect Your Bee Colony

- Who typically uses electric honey extractors? Essential for Large-Scale Commercial Beekeepers