In professional honey processing, filtering is a critical step for achieving commercial standards of quality and appearance. It is the primary method used to remove visible impurities such as wax particles, wood splinters, and other hive debris. This process results in a clearer, more consistent product with a longer shelf life, which is essential for meeting the expectations of the mass-market consumer.

While filtering is essential for creating the clear, liquid honey most consumers expect, it represents a fundamental choice. The process enhances visual appeal and stability at the potential cost of removing beneficial microscopic components like pollen, which defines the character of raw honey.

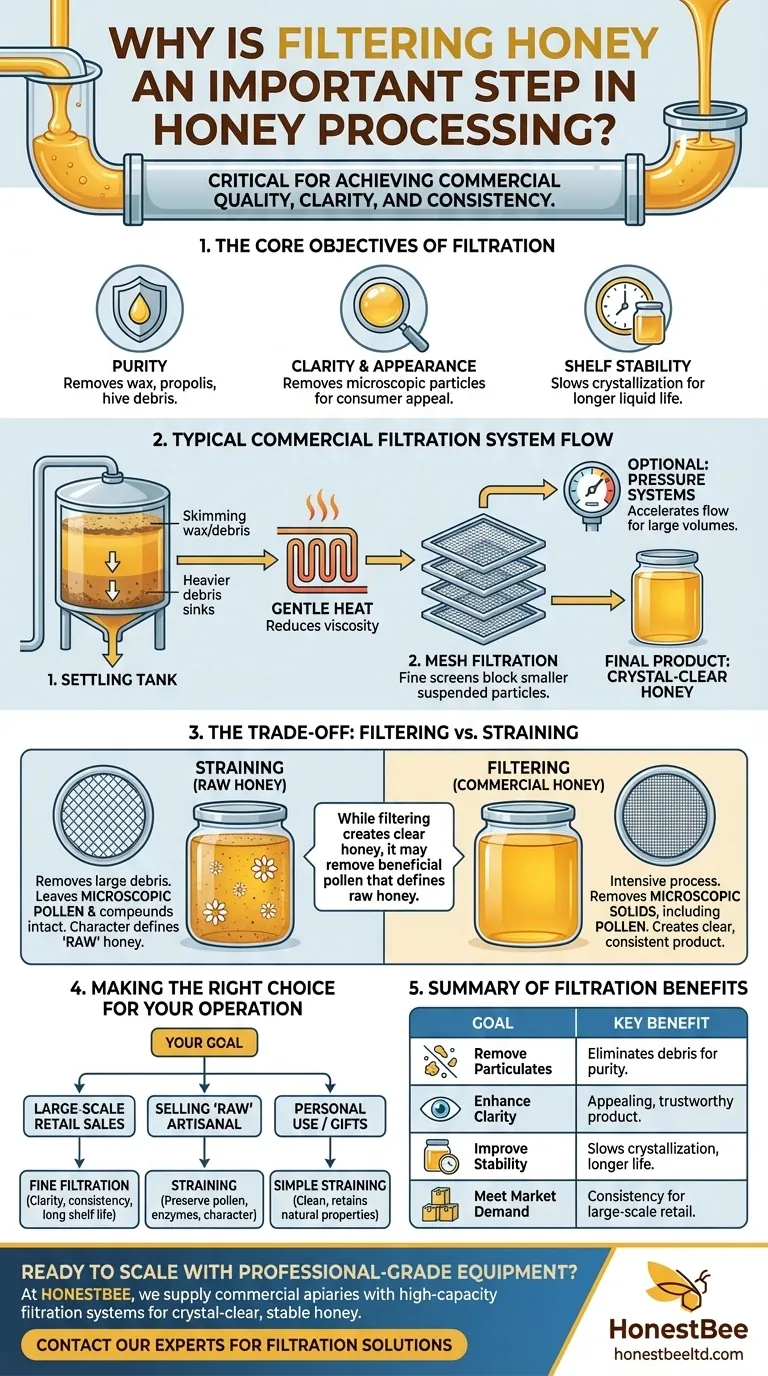

The Core Objectives of Honey Filtration

Filtering is not a single action but a process designed to achieve specific outcomes. The primary goals are purity, stability, and marketability.

Removing Undesirable Particulates

Raw honey, straight from the hive, contains a variety of materials besides honey. These include bits of beeswax, fragments of propolis, and other small debris. Filtration ensures these are physically removed.

Enhancing Clarity and Appearance

Consumers often associate clarity with purity. Filtering removes microscopic particles, including some pollen and air bubbles, that can make honey appear cloudy. The resulting crystal-clear product is highly valued in a retail setting.

Improving Shelf Stability

Small particles, including pollen grains and tiny sugar crystals, can act as nuclei for the crystallization process. By removing these, filtration can significantly slow down the rate at which honey solidifies, extending its liquid shelf life.

How a Typical Filtration System Works

Commercial filtration is a multi-stage process designed for efficiency and consistency. While systems vary, they generally follow a common sequence.

Step 1: The Settling Tank

Honey is first held in a large settling tank. Gravity does the initial work here, allowing larger, less dense particles like chunks of wax to float to the surface for skimming, while heavier debris sinks.

Step 2: Mesh Filtration

The honey is then passed through a series of fine mesh screens, typically made of nylon or metal. These screens physically block and remove smaller suspended particles that did not separate in the settling tank.

The Role of Gentle Heat

To facilitate this process, honey is often gently warmed. This lowers its viscosity (makes it more fluid), allowing it to pass through the fine filters more easily without requiring excessive pressure. This is not the same as pasteurization, which uses much higher heat.

Optional: Pressure Systems

In large-scale operations, pressure may be applied to accelerate the flow of honey through the filtration system. This makes the process faster and more efficient for handling large volumes.

Understanding the Trade-offs: Filtering vs. Straining

The term "filtering" is often used broadly, but in the context of honey, it's crucial to distinguish it from "straining." This distinction is at the heart of the "raw honey" debate.

What is Straining?

Straining removes only the largest and most obvious debris—things like bees, wax cappings, and wood splinters. This is typically done with a wider mesh screen. The goal is simply to clean the honey for consumption.

Crucially, straining leaves microscopic particles like pollen and other beneficial compounds intact. This is the standard method for producing honey that is sold as "raw."

What is Filtering?

Filtering is a more intensive process that uses a very fine mesh to remove even microscopic solids. This includes much of the pollen naturally present in the honey.

While this creates an exceptionally clear product, it fundamentally alters the honey from its natural state. Ultra-filtration can remove nearly all pollen, making it impossible to trace the honey's floral and geographic origin.

Making the Right Choice for Your Operation

Your approach to filtration should directly align with your end product and target market. There is no single "best" method; there is only the right method for your goal.

- If your primary focus is large-scale commercial sales: Fine filtration is necessary to achieve the clarity, consistency, and long shelf life that retail consumers expect.

- If your primary focus is selling "raw" or artisanal honey: Straining is the correct method to remove only large debris while preserving the natural pollen, enzymes, and character of the honey.

- If your primary focus is personal use or small-scale gifts: Simple straining is sufficient to ensure the honey is clean while retaining all of its natural properties and character.

Ultimately, understanding the distinction between simply cleaning honey and altering its composition is the key to producing a high-quality product that meets your specific goals.

Summary Table:

| Filtration Goal | Key Benefit |

|---|---|

| Remove Particulates | Eliminates wax, propolis, and hive debris for purity. |

| Enhance Clarity | Creates a clear, visually appealing product consumers trust. |

| Improve Stability | Slows crystallization for a longer liquid shelf life. |

| Meet Market Demand | Achieves the consistency required for large-scale retail sales. |

Ready to scale your honey production with professional-grade equipment?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-capacity, efficient filtration systems needed to produce crystal-clear, stable honey for the mass market. Our wholesale-focused operations ensure you get the durable, commercial-standard equipment required for large-volume processing.

Contact our experts today to discuss the best filtration solutions for your commercial goals.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Professional Stainless Steel Honey Filter with Support Handle

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

People Also Ask

- How does a honey filtering machine work? Achieve Market-Ready Clarity & Consistency

- What key attributes should industrial honey filtration systems possess? Master High Plant Diversity and Viscosity

- How do industrial-grade honey filtering systems enhance market competitiveness? Elevate Your Honey to Premium Standards

- What function does honey filtration and clarification equipment serve? Enhance Purity and Value in Your Production

- How do Industrial Honey Filtration Systems improve operational efficiency? Optimize Your Honey Processing Workflow

- What is the function of industrial-grade filtration in a honey Warehouse Receipt System (WRS)? Secure Your Asset Value

- What role does industrial-grade filtration equipment play in the production of raw honey? Enhance Purity and Quality

- What is the necessity of a 30μm sintered glass crucible? Master Honey Purity Detection Through Precision Filtration