In honey processing, filtering is a critical step for removing physical impurities like wax particles, bee parts, and other hive debris. This process is essential for creating a final product with superior clarity, a smoother texture, and an extended shelf life, which directly impacts its marketability and consumer appeal.

The core purpose of filtering honey is not just to clean it, but to transform a raw, variable product into a stable, consistent, and commercially valuable food item that meets consumer expectations for quality and purity.

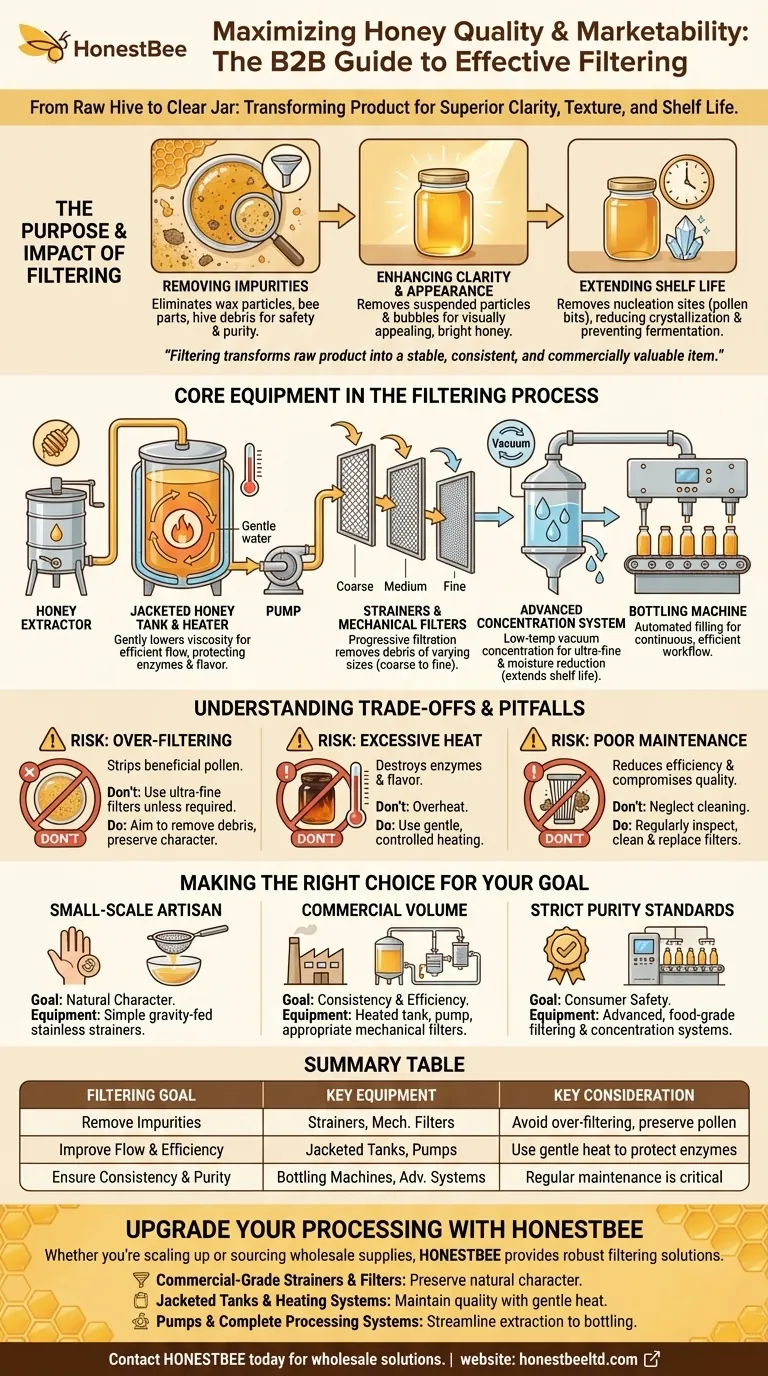

The Purpose and Impact of Filtering

Filtering is a foundational step that influences nearly every quality attribute of the final honey product, from its appearance in the jar to its stability over time.

Removing Physical Impurities

The primary goal is to remove any foreign material that is not honey. This includes bits of wax cappings, propolis, splinters from the hive, and any other small debris that may have been collected during the extraction process.

Enhancing Clarity and Appearance

Consumers often associate clear, bright honey with high quality. Filtering removes the suspended particles and fine air bubbles that can make honey look cloudy, resulting in a visually appealing product that stands out on the shelf.

Extending Shelf Life

Filtering removes fine particles, such as bits of pollen and wax, which can act as nucleation sites for crystallization. By removing these, the honey remains in a liquid state for a longer period, improving its shelf life and stability.

Core Equipment in the Filtering Process

The equipment used for filtering can range from simple, manual setups to complex, automated systems, depending on the scale of the operation.

Strainers and Mechanical Filters

This is the most fundamental equipment. Honey is passed through a series of screens or filters with progressively finer mesh. A coarse strainer might remove large wax particles, while a fine filter removes smaller debris.

Honey Tanks and Heaters

Honey is highly viscous, making it difficult to filter efficiently at room temperature. Jacketed honey tanks circulate warm water to gently heat the honey, lowering its viscosity so it flows more easily through the filters without damaging its natural enzymes and flavor.

Pumps and Bottling Machines

In commercial operations, pumps are used to move the honey from the extractor, through the tanks and filters, and finally to a bottling machine. This creates a continuous and efficient workflow, shortening the overall processing time.

Advanced Concentration Systems

Some advanced honey filter machines incorporate low-temperature vacuum concentration. This technology not only aids in removing very fine impurities but also gently removes excess water content, which helps prevent fermentation and further extends shelf life.

Understanding the Trade-offs and Pitfalls

While essential, the filtering process requires careful management to avoid common mistakes that can compromise the final product.

The Risk of Over-Filtering

Using filters that are too fine can strip the honey of beneficial components, most notably pollen. Many consumers seek out honey with pollen as it can be an indicator of its floral source and perceived health benefits. The key is to remove debris without removing the honey's natural character.

The Negative Impact of Excessive Heat

Heating makes filtering easier, but overheating is one of the most common mistakes in honey processing. High temperatures can destroy the delicate enzymes and aromatic compounds that give honey its unique flavor and health properties. Gentle, controlled heating is crucial.

The Need for Regular Maintenance

Filters and strainers will eventually become clogged. Failing to inspect, clean, and replace them regularly will dramatically reduce processing efficiency and can compromise the quality of the honey. Clean equipment is essential for adhering to food safety and sanitation standards.

Making the Right Choice for Your Goal

The right filtering strategy depends entirely on the scale of your operation and the type of product you want to create.

- If your primary focus is small-scale artisan production: A simple system of gravity-fed stainless steel strainers is often sufficient to produce a clean, high-quality product while preserving its natural character.

- If your primary focus is commercial volume and consistency: Investing in a complete system with a gently heated tank, a pump, and appropriately sized mechanical filters is necessary for efficiency and a uniform final product.

- If your primary focus is meeting strict purity standards: Advanced filtering systems that adhere to food-grade sanitation requirements are essential to ensure consumer safety and product quality.

Ultimately, mastering the filtering process is key to consistently producing safe, stable, and appealing honey.

Summary Table:

| Filtering Goal | Key Equipment Used | Key Consideration |

|---|---|---|

| Remove Impurities (wax, debris) | Strainers, Mechanical Filters | Avoid over-filtering to preserve pollen |

| Improve Flow & Efficiency | Jacketed Honey Tanks, Pumps | Use gentle heat to protect enzymes |

| Ensure Consistency & Purity | Bottling Machines, Advanced Filter Systems | Regular maintenance is critical for food safety |

Upgrade Your Honey Processing Efficiency with HONESTBEE

Producing honey that is consistently clear, stable, and market-ready requires the right equipment. Whether you are a commercial apiary scaling up production or a beekeeping equipment distributor sourcing reliable wholesale supplies, HONESTBEE provides the robust filtering and processing solutions you need.

We supply:

- Commercial-Grade Strainers & Filters: For removing impurities without stripping honey's natural character.

- Jacketed Tanks & Heating Systems: For gentle, controlled heating that maintains quality.

- Pumps & Complete Processing Systems: To streamline your workflow from extraction to bottling.

Let us help you achieve superior product quality and operational efficiency. Contact HONESTBEE today to discuss your specific needs and explore our wholesale-focused product lines.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- In what way does using a honey filtering machine extend the product's shelf life? Boost Stability & Market Value

- How is honey filtered after extraction? Choose the Right Method for Raw or Commercial Honey

- How does professional filtration equipment ensure the quality stability of honey? Secure Purity and Longer Shelf Life

- Why is precision filtration equipment essential in black honey processing? Achieve Premium Quality & Clarity

- How does using a honey filtering machine help in minimizing contamination? Ensure Pure, High-Quality Honey Standards

- What is the technical necessity of industrial honey filtration and concentration? Optimize Your Honey Processing Quality

- What role does industrial honey filtration play? Enhance Market Value with Professional Processing Equipment

- What is the necessity of a 30μm sintered glass crucible? Master Honey Purity Detection Through Precision Filtration