For one primary reason: honey is gently heated before filtering to temporarily reduce its viscosity, or thickness. This allows the honey to flow more easily through a filter, which is essential for removing small impurities like wax particles, pollen, and other debris. Without this step, the honey would be too thick to pass through fine filters efficiently.

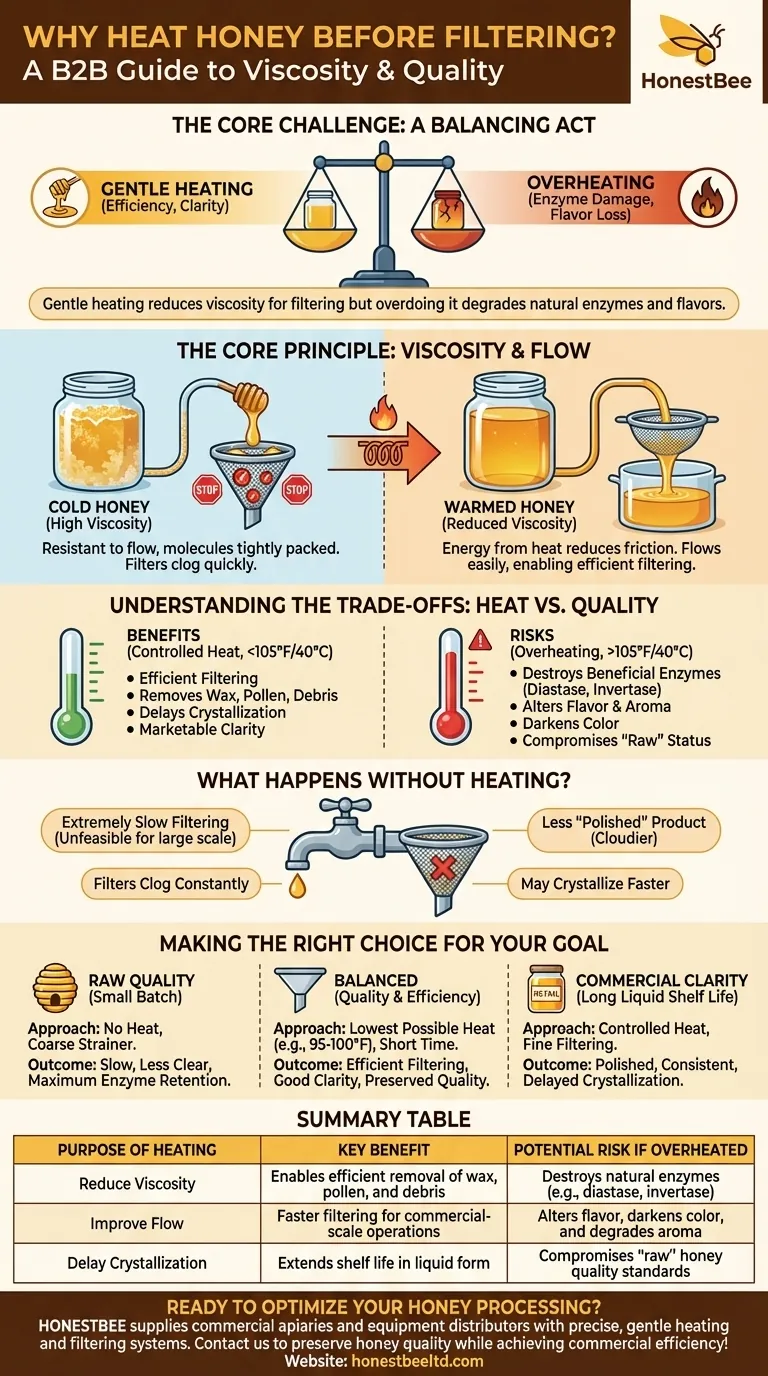

The core challenge in honey processing is a balancing act. Gentle heating is a practical necessity for creating a clear, marketable product, but overheating will permanently degrade the honey's natural enzymes, delicate flavors, and unique aromas.

The Core Principle: Viscosity and Flow

Honey in its natural state is a supersaturated sugar solution with very low water content, which makes it highly viscous. To process it effectively, you must temporarily change this physical property.

What is Viscosity?

Viscosity is a fluid's resistance to flow. Think of the difference between pouring water (low viscosity) and pouring cold molasses (high viscosity). Honey's high viscosity is due to the strong internal friction between its sugar molecules.

How Heat Reduces Viscosity

Applying gentle heat introduces energy into the honey. This energy makes the sugar molecules vibrate and move more freely, reducing the friction between them. As a result, the honey becomes thinner and flows much more readily, similar to how butter softens when warmed.

The Purpose of Filtering

The sole purpose of heating is to enable effective filtering. Filtering removes undesirable particles that can affect the honey's clarity, texture, and shelf life. This creates a more visually appealing product that consumers often prefer.

Understanding the Trade-offs: Heat vs. Quality

While heating solves the problem of viscosity, it introduces a significant risk. Honey is a delicate biological product, and excessive heat can cause irreversible damage.

The Danger of Overheating

Overheating honey is the most common mistake in processing. It can destroy beneficial enzymes, such as diastase and invertase, which are often used as markers of honey quality. It also cooks the delicate sugars, altering the flavor and darkening the color.

The "Raw Honey" Standard

Many processors aim to keep honey "raw," which generally means it has not been heated above the temperatures found naturally in a beehive, typically around 95-105°F (35-40°C). Exceeding this range begins the process of degradation.

Impact on Crystallization

Heating has a secondary effect: it dissolves the tiny sugar crystals that are naturally present in honey. This can significantly delay the onset of crystallization, which is why many large commercial producers heat their honey to ensure it remains liquid on the shelf for longer.

What Happens if You Don't Heat Honey?

Skipping the heating step is possible, but it comes with its own set of challenges that make it impractical for most producers beyond a very small scale.

Extremely Slow Filtering

Attempting to filter cool, viscous honey is an exercise in patience. The process is incredibly slow, and filters will clog almost immediately, requiring constant cleaning or replacement. This makes any large-scale operation unfeasible.

A Less "Polished" Product

Without efficient filtering, more microscopic particles (like fine pollen grains) may remain in the honey. While not harmful, this can result in a product that appears cloudier and may crystallize faster, which can be less appealing in a competitive market.

Making the Right Choice for Your Goal

Your approach to heating should be dictated entirely by the type of product you want to create and the scale of your operation.

- If your primary focus is maximum raw quality for a small batch: Use only coarse strainers to remove large debris and avoid heating altogether, accepting that the process will be slow and the final product may be less clear.

- If your primary focus is commercial clarity and a long liquid shelf life: Gentle, controlled heating is a necessary step to enable fine filtering and create the polished, consistent product that a broad market expects.

- If your primary focus is a balance of both: Use the lowest possible temperature (e.g., 95-100°F or 35-38°C) for the shortest time required to allow the honey to pass through your chosen filter.

Ultimately, remember that heat is a tool to manage a physical property, not a mandatory ingredient in the recipe.

Summary Table:

| Purpose of Heating | Key Benefit | Potential Risk if Overheated |

|---|---|---|

| Reduce Viscosity | Enables efficient removal of wax, pollen, and debris | Destroys natural enzymes (e.g., diastase, invertase) |

| Improve Flow | Faster filtering for commercial-scale operations | Alters flavor, darkens color, and degrades aroma |

| Delay Crystallization | Extends shelf life in liquid form | Compromises "raw" honey quality standards |

Ready to optimize your honey processing? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with wholesale-focused solutions for precise, gentle heating and filtering systems. Contact us today to preserve honey quality while achieving commercial efficiency!

Visual Guide

Related Products

- Professional Stainless Steel Honey Filter with Support Handle

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

People Also Ask

- How does the use of controlled heating equipment impact honey's H2O2 production? Protect Your Honey's Bioactivity

- What is the primary processing objective of using a thermostatic water bath for honey? Ensure Sample Accuracy

- What does heating up honey do? Uncover the Impact on Flavor and Nutrition

- How does industrial-grade temperature-controlled processing equipment help meet consumer preferences for honey viscosity?

- In what ways does a honey heating tank improve efficiency and save time? Master Viscosity for Faster Production

- How do honey heating tanks support scalability in beekeeping operations? Unlock Growth and Efficiency

- How do you make Crystallised honey runny again? The Safe & Simple Guide to Restoring Liquid Honey

- Why is the placement of temperature sensors critical for honey recrystallizer design? Protect Your Honey's Value