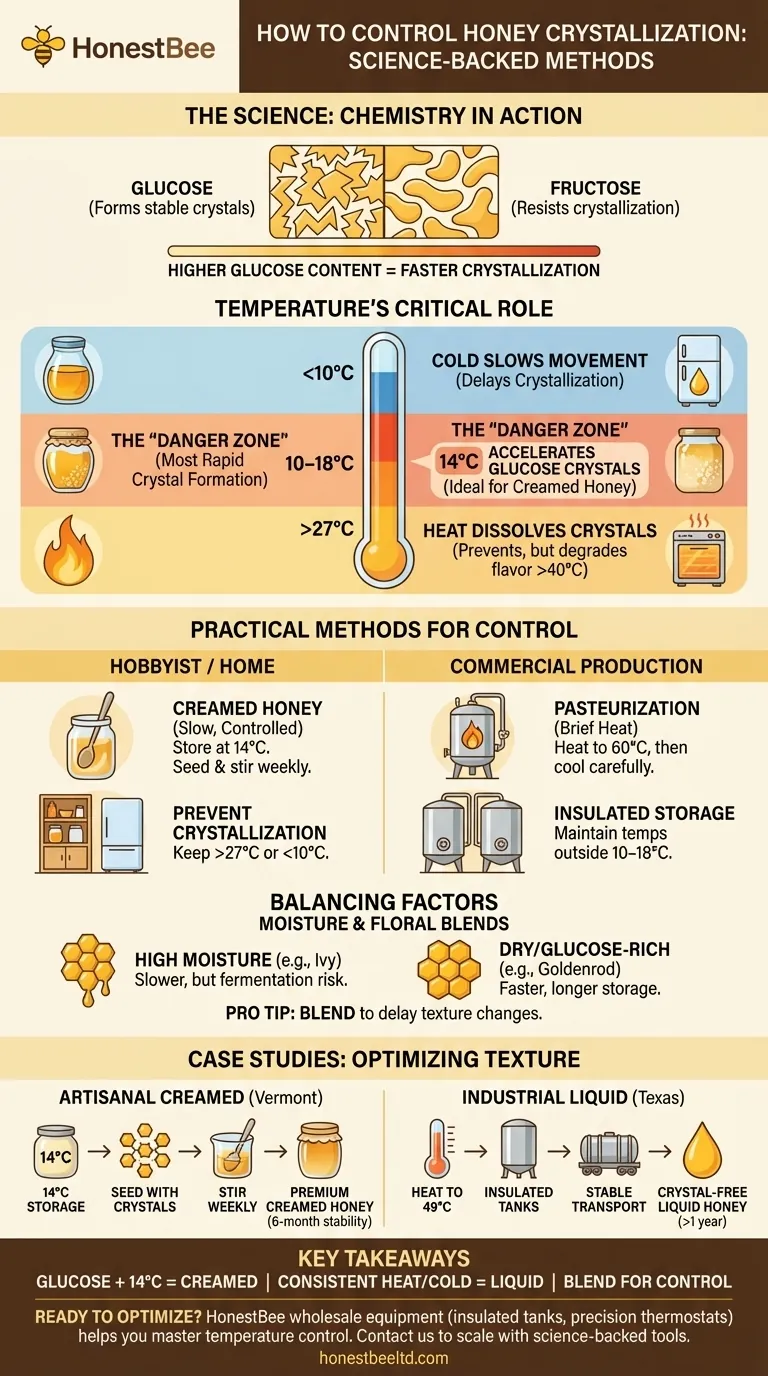

Honey crystallization isn’t a flaw—it’s chemistry in action. Whether you’re a hobbyist aiming for creamy honey or a commercial producer needing liquid consistency, temperature control holds the key. This guide breaks down the science and practical techniques to manage crystallization for any use case.

The Science of Honey Crystallization

Molecular Composition and Temperature Sensitivity

Honey crystallizes because of its sugar structure, primarily the balance between glucose and fructose. Glucose forms stable crystals, while fructose resists crystallization. Research shows honey with higher glucose content (like rapeseed or clover varieties) crystallizes faster—sometimes within weeks.

Why temperature matters:

- Below 10°C: Cold slows molecular movement, delaying crystallization.

- 10–18°C: The "danger zone" where glucose crystals form most rapidly.

- Above 27°C: Heat dissolves crystals, but excessive heat degrades flavor and enzymes.

Why 14°C Accelerates Glucose Crystal Formation

At 14°C, glucose molecules align into stable crystals with minimal energy. This is why:

- Artisanal producers use this range to create creamed honey (slow, controlled crystallization).

- Commercial facilities avoid this range to maintain liquid honey longer.

Practical Methods for Controlling Crystallization

Temperature Regulation Techniques

For Home Beekeepers:

- Slow crystallization: Store honey at 14°C for creamy textures (e.g., spreadable honey).

- Prevent crystallization: Keep honey above 27°C (e.g., warm pantries) or below 10°C (e.g., refrigerators).

For Commercial Production:

- Pasteurization: Brief heating to 60°C dissolves crystals but requires careful cooling to avoid re-crystallization.

- Insulated storage: Maintains temperatures outside the 10–18°C range during transit.

Balancing Moisture and Floral Variability

- High-moisture honey (e.g., from ivy) crystallizes slower but risks fermentation.

- Dry, glucose-rich honey (e.g., goldenrod) crystallizes faster but stores longer.

Pro Tip: Blend fast- and slow-crystallizing honeys to delay texture changes.

Case Studies in Honey Production

Artisanal Creamed Honey: Slow Crystallization at 14°C

A Vermont apiary uses precise 14°C storage to:

- Seed raw honey with fine crystals.

- Stir weekly for smooth, spreadable texture.

Result: Premium creamed honey with 6-month shelf stability.

Industrial Liquid Honey: Thermal Management

A Texas packing facility avoids crystallization by:

- Heating bulk honey to 49°C before bottling.

- Using insulated tanks to stabilize temperature during shipping.

Result: Liquid honey remains crystal-free for over a year.

Key Takeaways

- Glucose-rich honey + 14°C storage = Faster crystallization (ideal for creamed honey).

- Consistent heat/cold = Delayed crystallization (ideal for liquid honey).

- Floral blends and moisture control offer additional customization.

Ready to optimize your honey’s texture? HONESTBEE’s wholesale beekeeping equipment—from insulated storage tanks to precision thermostats—helps commercial apiaries and distributors master temperature control. Contact us to scale your honey production with science-backed tools.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

Related Articles

- How to Harvest Honeycombs Efficiently Without Compromising Quality or Bee Health

- How Honey Screw Presses Deliver Higher Yields With Less Waste

- The Physics of Patience: Mastering Honey Extractor Speed to Save Your Combs

- Beyond the Extractor: How Honey Presses Turn Waste into Profit for Commercial Apiaries

- The Last Drop: Maximizing Yield and Purity with a Stainless Steel Honey Press