Yes, bee escape boards are highly customizable, but customization is less about building a new device from scratch and more about selecting the right type of escape mechanism for your specific hive and harvesting goals. Different designs offer significant trade-offs between the speed of clearing bees and the risk of clogging, allowing you to tailor your approach to the needs of your apiary.

The core idea of "customizing" a bee escape is choosing the best design—such as a slow but gentle Porter escape or a fast multi-exit board—to match your desired harvest timeline and hive conditions. Success depends on selecting the right tool for the job.

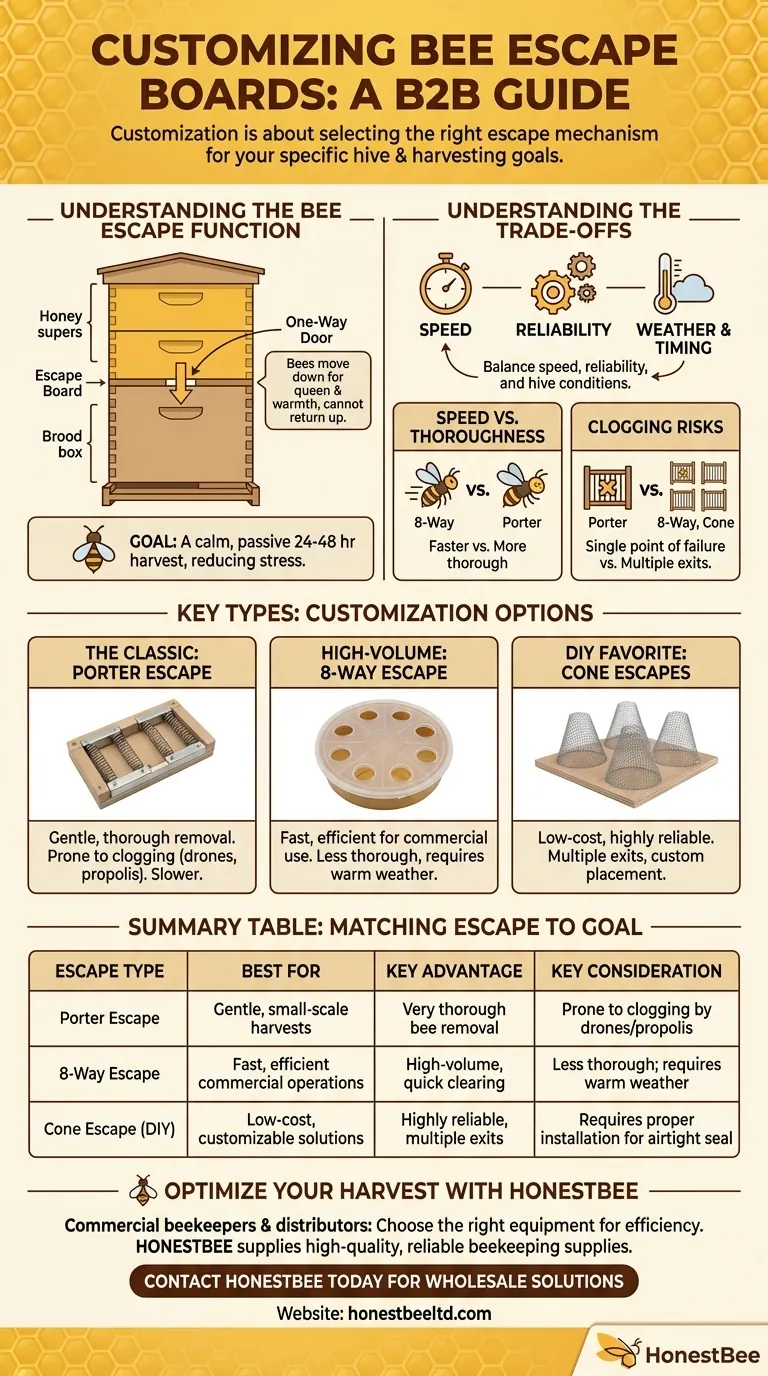

Understanding the Bee Escape's Function

A bee escape is fundamentally a one-way gate for bees. It is placed on a board (often called a clearer board or inner cover) between the honey supers you want to harvest and the brood boxes below.

The One-Way Door Principle

The design allows worker bees to move down into the brood chamber, following the queen's pheromones and the natural evening migration of the colony. However, the shape of the escape prevents them from finding their way back up into the honey super.

The Goal: A Calm and Passive Harvest

The purpose is to clear the honey supers of most bees over 24 to 48 hours. This passive method dramatically reduces bee stress and defensiveness compared to more forceful methods like using a bee brush or a fume board.

Key Types of Bee Escapes (The Customization Options)

Your primary method of customization is choosing from several established escape designs, each with distinct advantages.

The Classic: Porter Bee Escape

This is a small, traditional device with two flexible, spring-loaded gates. Bees can easily push through the springs to go down, but the springs close behind them, blocking re-entry. It is very effective at clearing nearly all the bees.

The High-Volume Option: 8-Way Escape

This is a round, plastic insert with eight separate exits. It allows a much larger volume of bees to leave the super at once. This design is significantly faster than the Porter escape and is the preferred choice for many commercial operations.

The DIY Favorite: Cone Escapes

These are simple cones made of wire mesh or plastic. Bees can easily crawl down and out through the wide end of the cone but are baffled when trying to re-enter through the narrow opening. Many beekeepers install several of these on a standard inner cover to create their own effective escape board.

Understanding the Trade-offs

Choosing the right design requires balancing speed, reliability, and the specific conditions of your hive.

Speed vs. Thoroughness

An 8-way escape is built for speed and can clear a super in a matter of hours in warm weather. A Porter escape is much slower, typically requiring a full 24 hours or more, but it often does a more thorough job of removing every last bee.

Clogging and Reliability

This is the most critical trade-off. Porter escapes are notorious for getting clogged. A single drone, which is too large to pass through, or a bit of propolis can render the entire device useless. Multi-exit escapes (like the 8-way or cone types) are far more reliable, as a clog in one exit still leaves several others open for bees to use.

Weather and Timing

All bee escapes work best in warm weather when bees are actively moving. If placed on the hive during a cold snap, bees may cluster in the super for warmth and will not move down, defeating the purpose of the board.

Proper Installation is Non-Negotiable

The escape board must create an airtight seal. Any cracks or gaps in your hive bodies or a poorly fitting lid will become a new entrance for bees to get back into the super, completely negating the one-way-door effect.

Making the Right Choice for Your Goal

Select your bee escape based on the size of your operation and your primary harvesting priority.

- If your primary focus is a gentle, small-scale harvest: A classic Porter escape is an excellent, time-tested tool, as long as you ensure it is clean and clear before installation.

- If your primary focus is speed and efficiency for multiple hives: An 8-way escape board is the superior option, dramatically reducing the risk of a failed clearing due to clogs.

- If your primary focus is a low-cost or DIY solution: Installing several cone escapes on an existing inner cover is a highly effective and reliable method you can build yourself.

Ultimately, matching the escape type to your specific needs is the key to a quiet and successful honey harvest.

Summary Table:

| Escape Type | Best For | Key Advantage | Key Consideration |

|---|---|---|---|

| Porter Escape | Gentle, small-scale harvests | Very thorough bee removal | Prone to clogging by drones/propolis |

| 8-Way Escape | Fast, efficient commercial operations | High-volume, quick clearing | Less thorough than Porter; requires warm weather |

| Cone Escape (DIY) | Low-cost, customizable solutions | Highly reliable, multiple exits | Requires proper installation for airtight seal |

Ready to Optimize Your Honey Harvest?

As a commercial beekeeper or equipment distributor, choosing the right bee escape board is critical for efficiency and hive health. HONESTBEE supplies a full range of high-quality, reliable beekeeping supplies and equipment, including various bee escape boards, designed specifically for the demands of commercial apiaries and wholesale operations.

Let our experts help you select the perfect equipment to maximize your harvest and minimize stress on your colonies. Contact HONESTBEE today to discuss your needs and get a quote on our wholesale-focused solutions!

Visual Guide

Related Products

- Circular Labyrinth Bee Escape for Efficient Hive Management

- HONESTBEE Multi Exit Plastic Bee Escape Board for Efficient Honey Harvesting

- HONESTBEE 4-Way Metal Corner Wooden Bee Escape Board

- High-Efficiency Diamond Maze Bee Escape for Clearing Supers

- HONESTBEE Wooden Bee Escape Board with Triangle Mesh Design for Beekeeping

People Also Ask

- How long should you wait after placing a bee escape board before harvesting honey? Clear Your Supers in 24-48 Hours

- What happens if Triangular Escape Boards are left on for more than 24 hours? Risk of Bee Re-Entry and Failed Harvest

- What is the recommended procedure for using a triangle bee escape board? Master a Stress-Free Honey Harvest

- How is a bee escape board used and how does it function? Master This Gentle Honey Harvesting Tool

- How long should a bee escape be placed before harvesting honey? The 24-48 Hour Guide to a Stress-Free Harvest