Yes, honey-filling machines are readily available in both semi-automatic and fully automatic configurations. While both perform the same core function, they are designed for vastly different operational scales, budgets, and levels of efficiency. The choice between them is a critical strategic decision for any honey producer.

Your choice isn't simply about automation; it's about aligning the machine's capabilities with your business's specific production volume, labor costs, and future growth ambitions. The right machine removes a bottleneck, while the wrong one can become one.

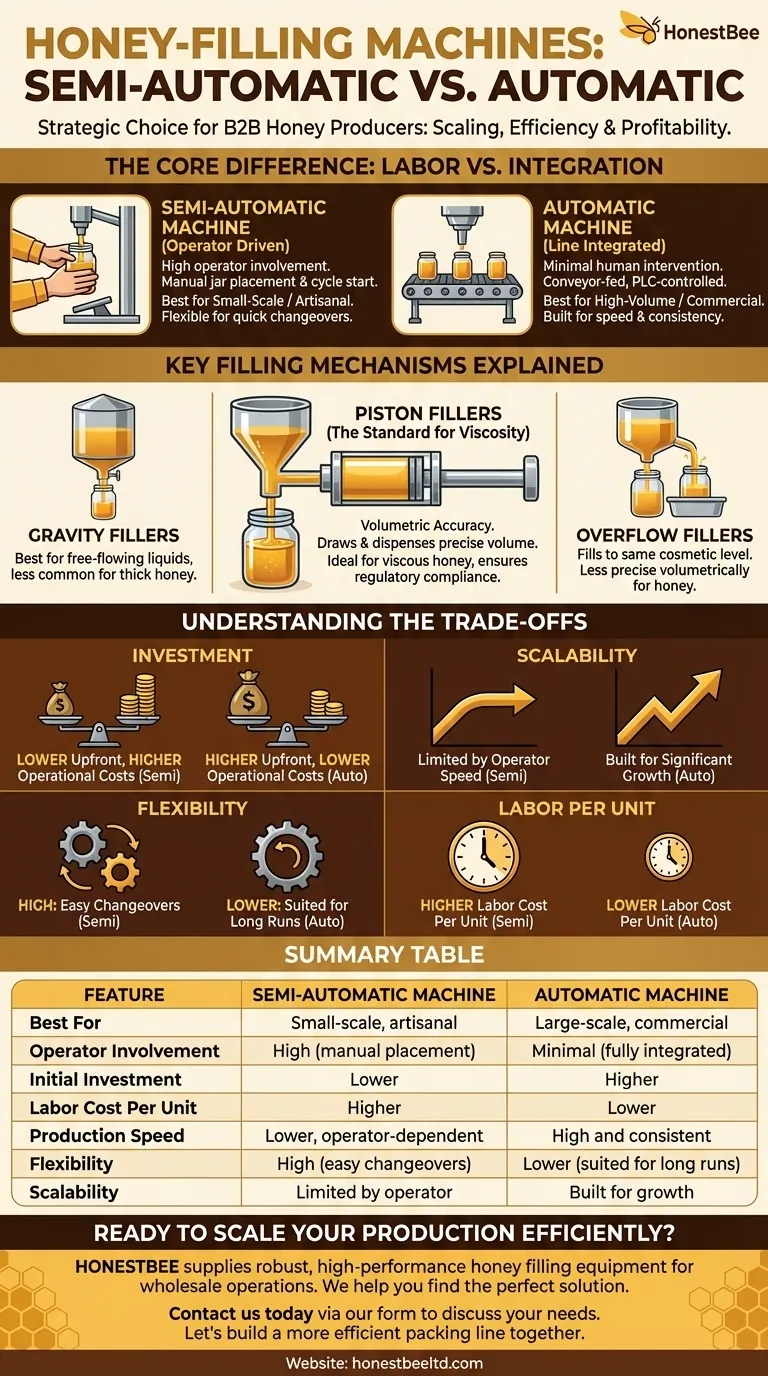

The Core Difference: Labor vs. Integration

The fundamental distinction between semi-automatic and automatic machines lies in the degree of operator involvement and how they integrate into a production line.

What Defines a Semi-Automatic Machine?

A semi-automatic filler requires an operator for key steps. Typically, the operator must manually place each jar or container under the filling nozzle and then activate the fill cycle, often with a foot pedal or push-button.

These machines are excellent for small-scale or artisanal producers. They offer significant flexibility for handling various container sizes and honey types with relatively quick changeovers.

What Defines an Automatic Machine?

An automatic machine is designed for minimal human intervention. It integrates a conveyor system that moves containers into position, fills them, and moves them along to the next station (such as capping or labeling) automatically.

These systems are controlled by a PLC (Programmable Logic Controller) and are built for high-speed, high-volume, and continuous operation. They ensure exceptional consistency and dramatically reduce per-unit labor costs.

Key Filling Mechanisms Explained

The technology used to move the honey is just as important as the level of automation. Because honey is viscous, the filling mechanism is critical for accuracy and speed.

Piston Fillers: The Standard for Viscosity

The most common and effective mechanism for honey is the piston filler. This machine uses a cylinder to pull a precise volume of honey from a hopper and then dispense that exact amount into the container.

Its primary advantage is volumetric accuracy. This ensures you are not over-filling or under-filling jars, which is crucial for profitability and regulatory compliance.

Gravity and Overflow Fillers

Gravity fillers work best with free-flowing, low-viscosity liquids and are less common for thick honey. Overflow fillers are designed to fill each container to the same cosmetic level, which can be useful for transparent packaging, but may not be as volumetrically precise as a piston filler.

Understanding the Trade-offs

Choosing the right machine requires a clear-eyed assessment of the costs, benefits, and limitations of each type.

The Investment: Upfront vs. Operational Costs

Semi-automatic machines have a much lower initial purchase price, making them accessible for startups and small businesses. However, their reliance on an operator means higher long-term operational and labor costs per jar.

Automatic machines require a significant upfront capital investment. Their payoff comes from vastly lower labor costs at scale, higher throughput, and unwavering consistency that minimizes product waste.

The Scalability Factor

A semi-automatic machine is perfect for getting started, but it has a clear production ceiling defined by the speed of your operator. It can quickly become a bottleneck as your business grows.

An automatic machine is built for scale. It may be underutilized in a small operation, but it provides the capacity for significant growth without a corresponding increase in labor.

Flexibility and Changeover

Semi-automatic fillers are generally more flexible. Cleaning them and adjusting for different jar sizes or honey varieties is often a simpler, faster process. This is ideal for producers offering a wide range of products in small batches.

Automatic lines are less agile. A changeover can be more complex and time-consuming, making them better suited for long production runs of a single product format.

Making the Right Choice for Your Operation

Base your decision on a realistic assessment of your current needs and future goals.

- If your primary focus is starting a small, artisanal, or farm-stand business: A semi-automatic piston filler offers the best balance of affordability, accuracy, and flexibility.

- If your primary focus is scaling up an existing operation for wholesale or retail distribution: An automatic filling line is a necessary investment to achieve the efficiency, speed, and low per-unit cost required for growth.

- If your primary focus is product versatility and frequent small batches: The quick changeover and lower cost of a semi-automatic machine will serve you better than a high-capacity automatic line.

Ultimately, the best machine is the one that seamlessly fits the scale and strategy of your operation.

Summary Table:

| Feature | Semi-Automatic Machine | Automatic Machine |

|---|---|---|

| Best For | Small-scale, artisanal producers | Large-scale, commercial apiaries |

| Operator Involvement | High (manual container placement) | Minimal (fully integrated line) |

| Initial Investment | Lower | Higher |

| Labor Cost Per Unit | Higher | Lower |

| Production Speed | Lower, operator-dependent | High and consistent |

| Flexibility | High (easy changeovers) | Lower (suited for long runs) |

| Scalability | Limited by operator speed | Built for significant growth |

Ready to Scale Your Honey Production Efficiently?

As a commercial apiary or beekeeping equipment distributor, choosing the right filling machine is crucial for your profitability and growth. HONESTBEE supplies robust, high-performance honey filling equipment designed for wholesale operations.

We help you navigate the choice between semi-automatic and automatic systems to find the perfect solution that maximizes your output and minimizes costs.

Contact us today via our [#ContactForm] to discuss your specific needs and get a personalized quote. Let's build a more efficient and profitable honey packing line together.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What technical advantages do industrial-grade honey filling machines provide? Boost Your Large-Scale Honey Production

- How can honey be packed into containers? Compare Manual vs. Automatic Filling Solutions

- What is the value of honey filling and packaging machinery? Accelerate Commercial Scalability and Global Market Access

- How does a VFFS liquid packaging machine handle honey packaging? Master Viscous Liquid Filling

- What technical advantages do industrial honey filling machines provide? Boost Precision and Quality in Processing

- How does the feeding system work in automated honey filling machines? A Guide to Viscosity & Volume

- What is the industrial value of honey-filling machines? Scale Your Production and Maximize Retail Profitability

- What are the technical advantages of high-precision honey filling equipment? Boost Accuracy and Commercial Scalability