Yes, you can bottle honey immediately after extraction, but doing so bypasses several crucial processing steps that ensure the quality, clarity, and long-term stability of the final product. While technically possible, most beekeepers strain or filter the honey first to remove impurities and verify its water content is low enough to prevent fermentation.

The decision to bottle honey right after extraction is a trade-off between speed and quality. While immediate bottling is the fastest method, taking the time to filter and settle your honey first is the standard practice for creating a clear, pure, and shelf-stable product.

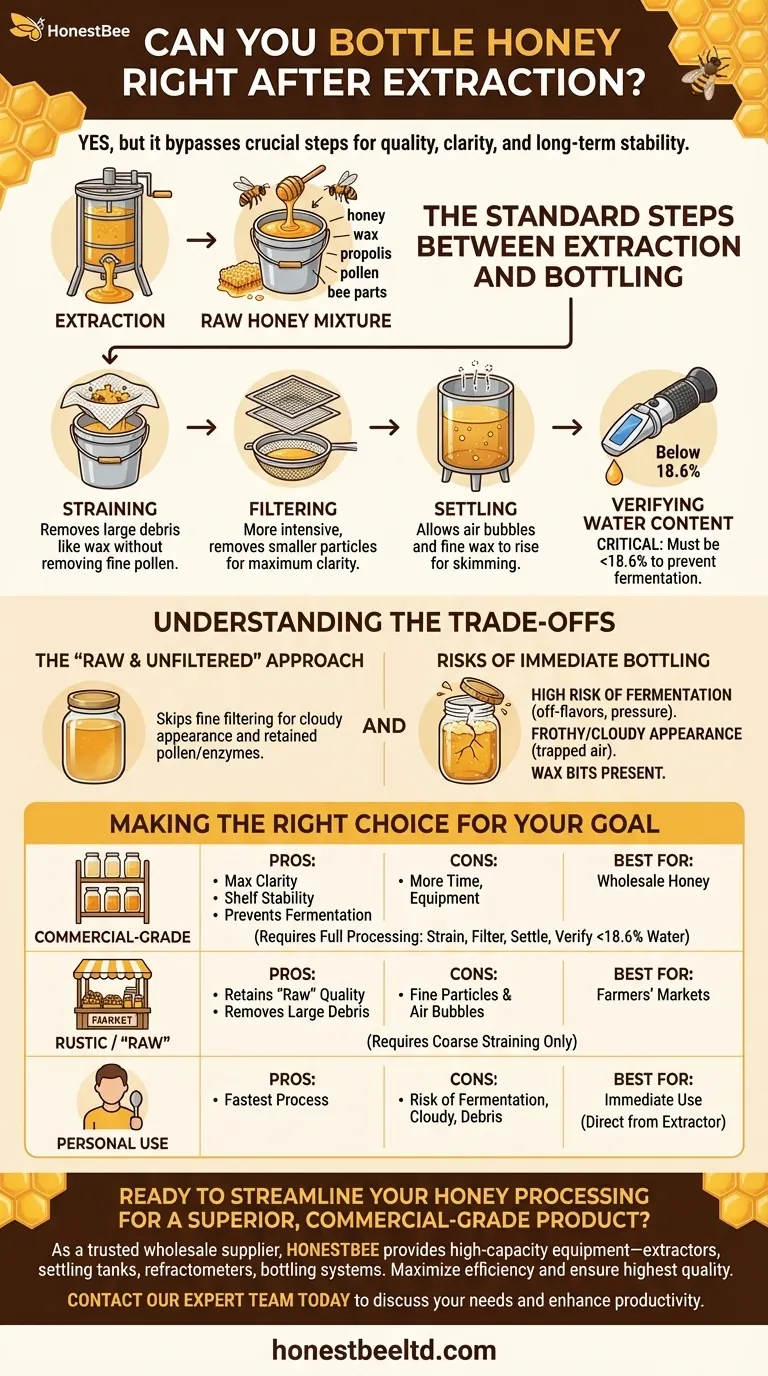

The Standard Steps Between Extraction and Bottling

Honey straight from an extractor contains more than just pure honey. It's a mixture that includes wax cappings, propolis, pollen, and occasionally bee parts. The following steps are designed to refine this raw mixture into a finished product.

Straining to Remove Large Debris

The most basic and essential step is straining. This process is designed to remove the larger visible impurities from your honey.

Straining is typically done using materials like cheesecloth or a nylon filter placed over a bucket. The goal is simply to catch bits of beeswax and other debris without removing the fine particles like pollen.

Filtering for Maximum Clarity

Filtering is a more intensive process than straining. It uses finer mesh screens to remove smaller suspended particles, including some pollen grains.

Many beekeepers use a two-stage filter system or a combination honey sieve and bottling tank. This streamlines the process and results in the crystal-clear honey that consumers often expect.

Settling to Remove Air Bubbles

After extraction and filtering, honey is often pumped into a holding tank to rest for a day or two. This is called settling.

Gravity does the work during settling. Tiny air bubbles introduced during the extraction process rise to the surface, along with any remaining fine wax particles. This layer can then be skimmed off before bottling, further improving the honey's clarity.

Verifying Water Content

This is arguably the most critical step for long-term storage. Honey with a water content above 18.6% is at risk of fermenting.

Beekeepers use a tool called a refractometer to measure the water content. Ensuring the honey is "ripe"—meaning the bees have capped the cells—is the best way to start with a low water content.

Understanding the Trade-offs

Choosing to skip these steps is a valid decision, but it's important to understand what you are giving up in exchange for speed.

The "Raw & Unfiltered" Approach

Some producers intentionally skip fine filtering to market their product as "raw and unfiltered." They embrace the cloudier appearance as a sign that beneficial pollen and enzymes have been retained. However, even these producers will typically perform a coarse straining to remove large wax pieces and debris.

The Risk of Fermentation

The greatest risk of bottling immediately is packaging honey with a high water content. If the honey ferments in the jar, it will develop off-flavors and pressures that can pop the lid. This makes the product unsellable and undesirable.

The Impact on Appearance

Bottling honey that hasn't settled will trap air bubbles, giving it a frothy or cloudy appearance. While this doesn't affect the taste, it can be unappealing to customers who are accustomed to clear, golden honey. Small bits of wax may also be present, which can be perceived as a defect.

Making the Right Choice for Your Goal

Your bottling process should align with the intended use of your honey.

- If your primary focus is a shelf-stable, commercial-grade product: You must strain, settle, and verify the water content is below 18.6% before bottling.

- If your primary focus is rustic, "raw" honey for farmers' markets: Perform a coarse straining to remove large debris but feel comfortable skipping fine filtering and settling.

- If your primary focus is speed for immediate personal use: You can bottle directly from the extractor, but understand the product may have cosmetic imperfections and should be stored properly.

Ultimately, understanding these post-extraction steps empowers you to control the final character and quality of your honey.

Summary Table:

| Bottling Method | Pros | Cons | Best For |

|---|---|---|---|

| Immediate Bottling | Fastest process | Risk of fermentation; Cloudy appearance with debris | Immediate personal use |

| Straining Only | Retains 'raw' quality; Removes large debris | May still contain fine particles and air bubbles | Rustic, farmers' market honey |

| Full Processing (Strain, Filter, Settle) | Maximum clarity & shelf stability; Prevents fermentation | Requires more time and equipment | Commercial-grade, wholesale honey |

Ready to streamline your honey processing for a superior, commercial-grade product?

As a trusted wholesale supplier to commercial apiaries and distributors, HONESTBEE provides the high-capacity equipment you need—from extractors and settling tanks to refractometers and bottling systems. Our solutions are designed to help you maximize efficiency and ensure every batch meets the highest quality standards.

Contact our expert team today to discuss your operation's needs and discover how our beekeeping supplies can enhance your productivity and product quality.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Thermostatic Conical Honey Melter

People Also Ask

- What is the role of Automated Honey-filling Machines? Scale Your Honey Brand with Precision and Safety

- How do industrial honey filling machines protect the biological activity of honey? Ensure Nutritional Integrity

- What benefits do industrial-grade filling machines provide? Secure Honey Quality and Hygiene with Precision Automation

- What are the advantages of using automated honey filling equipment? Scaling Your Commercial Honey Production

- What are the economic benefits of automated honey filling systems? Boost ROI in Large-Scale Commercial Apiaries