At its core, calibrating a filling machine is the systematic process of adjusting its dispensing mechanism and verifying its output to ensure it consistently delivers the correct amount of product into every container. This involves running test cycles, measuring the actual fill volume or weight with precision instruments, and fine-tuning the machine's settings until the output reliably falls within a predefined tolerance.

The goal of calibration is not just to hit a target number, but to create a repeatable and verifiable process. It transforms filling from an approximation into a precise manufacturing step, directly protecting your profitability and brand reputation by minimizing waste and ensuring compliance.

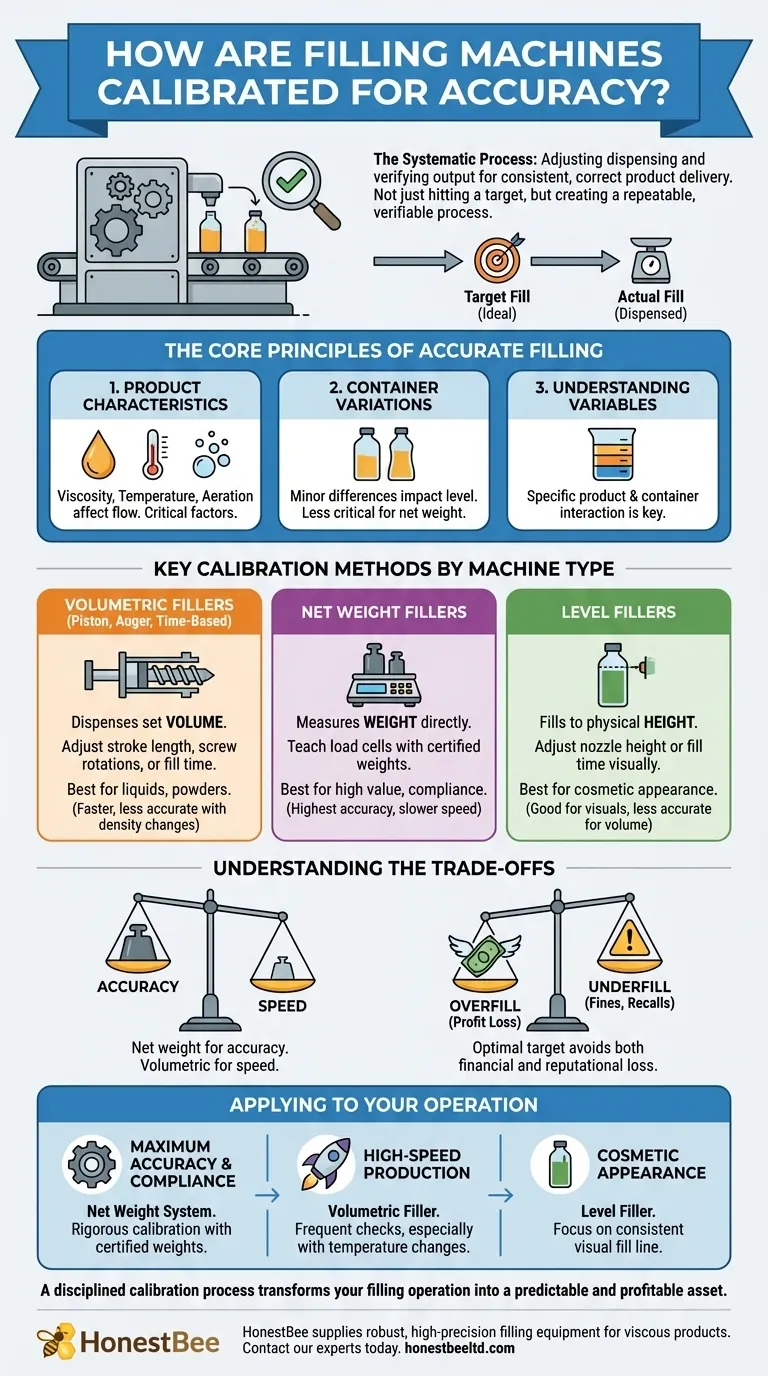

The Core Principles of Accurate Filling

Before adjusting any settings, you must understand the variables that impact accuracy. A filling machine doesn't exist in a vacuum; it operates on a specific product and container, both of which have inherent variations.

The Target vs. The Reality

The "target fill" is the ideal amount of product specified for the package (e.g., 500g). The "actual fill" is what the machine dispenses. Calibration is the process of closing the gap between these two values and, just as importantly, ensuring the variation between individual fills is minimal.

Why Product Characteristics Are Critical

The physical properties of your product are the single greatest factor influencing filler performance.

- Viscosity: A low-viscosity liquid like water flows quickly and stops abruptly. A high-viscosity product like honey or cream flows slowly and may "string" or drip after the valve closes, requiring different nozzle and timing settings.

- Temperature: A change in product temperature can alter its density and viscosity. A liquid that is filled hot will occupy more volume than the same weight of that liquid once it cools, a critical factor for volumetric fillers.

- Aeration and Foaming: Products that foam easily require slower fill speeds or specialized subsurface filling nozzles to prevent air from being trapped, which would result in an underfilled container by volume.

How Container Variations Impact Fills

No two containers are perfectly identical. Minor variations in the manufacturing of glass or plastic bottles can lead to slight differences in internal volume. For a level filler, this means two visually identical fill heights could contain different product volumes. For a net weight filler, this is irrelevant.

Key Calibration Methods by Machine Type

The specific calibration procedure depends entirely on the technology the machine uses to dispense the product.

Calibrating Volumetric Fillers (Piston, Auger, Time-Based)

These machines dispense a set volume of product.

A piston filler is calibrated by adjusting the length of the piston's stroke. A longer stroke draws in and dispenses more product. You calibrate by weighing the output of a test fill and adjusting the stroke length until the corresponding weight is consistently correct.

An auger filler for powders is calibrated by adjusting the number of rotations the screw makes per cycle. More rotations dispense more product.

A timed-flow filler is calibrated by changing the amount of time the fill valve stays open.

Calibrating Net Weight Fillers

These machines are inherently more accurate for many applications because they measure the weight of the product directly, ignoring variations in density, temperature, or aeration.

Calibration involves using certified, known weights to "teach" the machine's load cells. You place a 100g certified weight on the scale and tell the machine's software "this is 100g." This ensures the instrument measuring the fill is accurate before the production run even begins.

Calibrating Level Fillers

These machines fill each container to the same physical height, which is ideal for transparent packaging where cosmetic appearance is key.

Calibration is often a more manual or visual process. You adjust the nozzle height or fill time on one bottle until the level is correct, then set the other nozzles to match. This method is less accurate for guaranteeing volume due to container inconsistencies.

Understanding the Trade-offs

Choosing and calibrating a filling system involves balancing competing priorities. There is no single "best" method for all applications.

Accuracy vs. Speed

Volumetric fillers are typically faster than net weight fillers. However, their accuracy is more susceptible to changes in product density. Net weight fillers deliver superior accuracy by weighing each dose but may have a lower output in containers per minute.

The Cost of Overfill vs. Underfill

Overfilling is giving away free product with every container, which directly erodes profit margins. A seemingly tiny 1% overfill on millions of units is a significant financial loss.

Underfilling can lead to customer complaints, regulatory fines, and forced recalls. The damage to brand reputation can be far more costly than the product itself. Proper calibration finds the optimal target to avoid both extremes.

The Myth of "Set It and Forget It"

Calibration is not a one-time event. It is a continuous process. Machines must be recalibrated at the start of every shift, after every product or container changeover, and periodically during long production runs to compensate for environmental or product changes.

Applying This to Your Operation

Your calibration strategy should be directly tied to your product, container, and business goals.

- If your primary focus is maximum accuracy and regulatory compliance (e.g., pharmaceuticals, high-value chemicals): Your best choice is a net weight filling system. Implement a rigorous calibration schedule using certified weights and document every adjustment.

- If your primary focus is high-speed production of consistent liquids (e.g., beverages, oils): A well-maintained volumetric filler offers an excellent balance of speed and precision. Plan for frequent calibration checks using a scale, especially if product temperature varies.

- If your primary focus is cosmetic appearance in clear containers (e.g., window cleaner, some spirits): A level filler is often sufficient. Your calibration will be focused on achieving a consistent visual fill line across all containers.

A disciplined calibration process transforms your filling operation from a source of uncertainty into a predictable and profitable asset.

Summary Table:

| Calibration Method | Best For | Key Adjustment |

|---|---|---|

| Volumetric (Piston/Auger) | Liquids, Powders | Stroke Length / Screw Rotations |

| Net Weight | High-Value Products, Compliance | Load Cell Settings |

| Level Filling | Visual Appearance | Nozzle Height / Fill Time |

Stop losing money to inaccurate fills. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the robust, high-precision filling equipment needed to handle viscous products like honey and cremes. Our wholesale-focused operations ensure you get reliable machinery that protects your profit margins. Contact our experts today to discuss the right filling solution for your operation.

Visual Guide

Related Products

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Automatic Honey Frame Uncapper Machine for Beekeeping

- HONESTBEE 4 Frame Manual Self Reversing Honey Extractor for Beekeeping

- Adjustable Stainless Steel Honey Uncapping Fork with Scraper Beekeeping Tool

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

People Also Ask

- What are the processing values of honey filtering and filling equipment? Enhance Safety and Purity in Honey Production

- Why is high-automation filling machinery essential for bee pollen? Maximize Product Integrity and Scaling Potential

- Why is the use of professional filling and sealing packaging machinery necessary for the production of high-value honey?

- Why are professional honey filling machines and specialized packaging consumables vital for quality control?

- Why should ease of cleaning and maintenance be considered when selecting a honey packaging machine? Ensure Purity & ROI

- How do industrial honey-filling machines enhance the honey production value chain? Scale Your Apiary Business Efficiency

- How does the status of nectar and pollen sources guide the selection of honey filtration and filling equipment?

- How can honey be packed into containers? Compare Manual vs. Automatic Filling Solutions