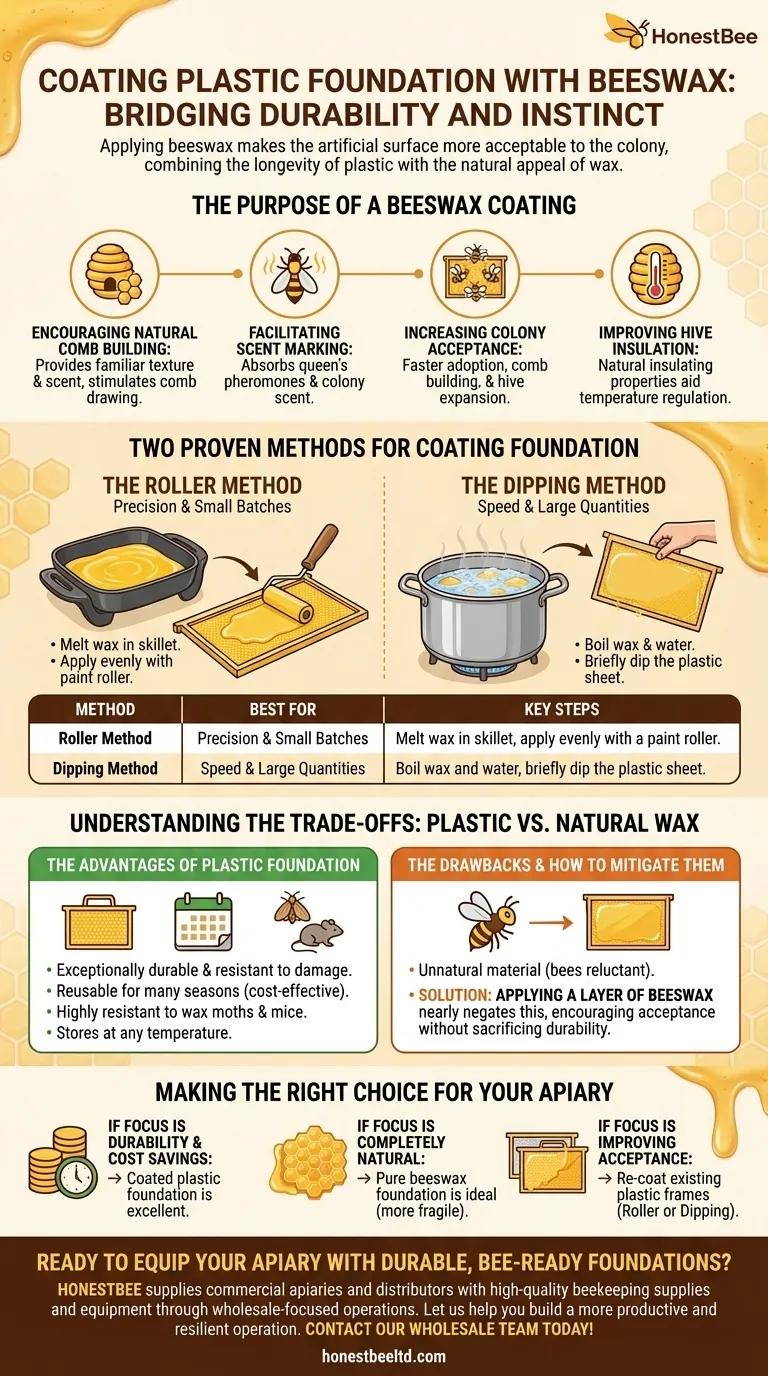

To coat plastic foundation with beeswax, you can either melt the wax in a skillet and apply it evenly with a paint roller, or boil wax and water in a deep bucket and briefly dip the plastic sheets into the mixture. Both methods create a familiar and enticing surface for the bees.

The core challenge with plastic foundation is bridging the gap between its durability and the bees' natural instincts. Applying a layer of beeswax makes the artificial surface more acceptable to the colony, combining the longevity of plastic with the natural appeal of wax.

The Purpose of a Beeswax Coating

Bees are naturally hesitant to build their intricate comb structures on a foreign plastic surface. A beeswax coating is a critical step to encourage their acceptance and kickstart comb construction.

Encouraging Natural Comb Building

The layer of beeswax provides a familiar texture and scent. This makes the interaction less jarring for the bees and stimulates their natural instinct to draw out comb.

Facilitating Scent Marking

Bees communicate heavily through scent. The wax coating readily absorbs the queen's pheromones and the colony's unique scent, signaling that the foundation is an accepted part of the hive.

Increasing Colony Acceptance

A colony is more likely to quickly adopt and utilize a foundation that feels and smells like something they produced themselves. This leads to faster comb building and hive expansion.

Improving Hive Insulation

Wax has natural insulating properties. Adding a layer to the plastic foundation contributes, even in a small way, to the hive's ability to regulate its internal temperature.

Two Proven Methods for Coating Foundation

There are two primary, effective methods for applying beeswax to your plastic foundation sheets. The choice often comes down to the equipment you have available and the number of frames you need to coat.

The Roller Method

This method offers precise control over the thickness of the wax layer.

First, melt your beeswax in a large electric skillet or a similar shallow, heated pan.

Once the wax is fully melted, use a small paint roller to pick up a thin layer of wax and apply it evenly across the surface of the plastic foundation.

The Dipping Method

This technique is faster for coating a large number of sheets at once.

You will need a deep stainless steel bucket or pot tall enough to submerge a frame. Fill it partway with water and add your beeswax.

Bring the mixture to a boil. The wax will melt and float on top of the water.

Quickly insert a plastic sheet into the hot liquid and withdraw it immediately. The sheet will emerge with a thin, even coating of pure beeswax.

Understanding the Trade-offs: Plastic vs. Natural Wax

Choosing a foundation material involves balancing durability, cost, and the natural preferences of your bees. A wax coating helps mitigate the primary drawback of using plastic.

The Advantages of Plastic Foundation

Plastic is exceptionally durable and resistant to damage during honey extraction.

It is reusable for many seasons, making it a cost-effective long-term investment.

Plastic is also highly resistant to damage from pests like wax moths and mice, and it can be stored at any temperature without degrading.

The Drawbacks and How to Mitigate Them

The primary downside is the introduction of an unnatural material into the hive. Bees can be reluctant to draw comb on plain, uncoated plastic.

Applying a layer of beeswax, especially a heavy one, almost entirely negates this disadvantage. It creates a surface that bees readily accept, giving you the structural benefits of plastic without the slow adoption rates.

Making the Right Choice for Your Apiary

Your decision should be guided by your specific goals for hive management, cost, and labor.

- If your primary focus is durability and long-term cost savings: Coated plastic foundation is an excellent choice, as it is reusable and highly resilient.

- If your primary focus is a completely natural hive environment: Pure beeswax foundation remains the ideal option, though you must accept its relative fragility.

- If your primary focus is improving bee acceptance of existing plastic frames: Re-coating them using either the roller or dipping method is a highly effective way to encourage faster comb construction.

Ultimately, understanding how to properly coat plastic foundation empowers you to make the best use of modern materials while respecting the natural instincts of your bees.

Summary Table:

| Method | Best For | Key Steps |

|---|---|---|

| Roller Method | Precision & small batches | Melt wax in skillet, apply evenly with a paint roller. |

| Dipping Method | Speed & large quantities | Boil wax and water, briefly dip the plastic sheet. |

Ready to equip your apiary with durable, bee-ready foundations? HONESTBEE supplies commercial apiaries and distributors with high-quality beekeeping supplies and equipment through wholesale-focused operations. Let us help you build a more productive and resilient operation. Contact our wholesale team today to discuss your needs!

Visual Guide

Related Products

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Food Grade Plastic bee Foundation for Bee Frames

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

People Also Ask

- What role does well-waxed plastic foundation play in preventing honey frame blowouts? Secure Your Harvest Stability

- What are the characteristics of plastic foundations for beehives? Durability and Longevity for Modern Beekeeping

- What is the purpose of applying a thin layer of beeswax to plastic hive foundations? Boost Colony Acceptance & Growth

- Why is it beneficial to coat plastic foundation with beeswax? Boost Hive Acceptance & Comb Building

- Can bees produce natural wax comb with plastic honey frames? Achieving the Perfect Balance in Your Hive

- What are the benefits of using black plastic foundation? Boost Efficiency for Commercial Apiaries

- Why is heavy waxing important for plastic foundation? Ensure Rapid, Uniform Comb Building

- Why is the use of pesticide-free beeswax coating essential for plastic foundations? Ensure Hive Health and Acceptance