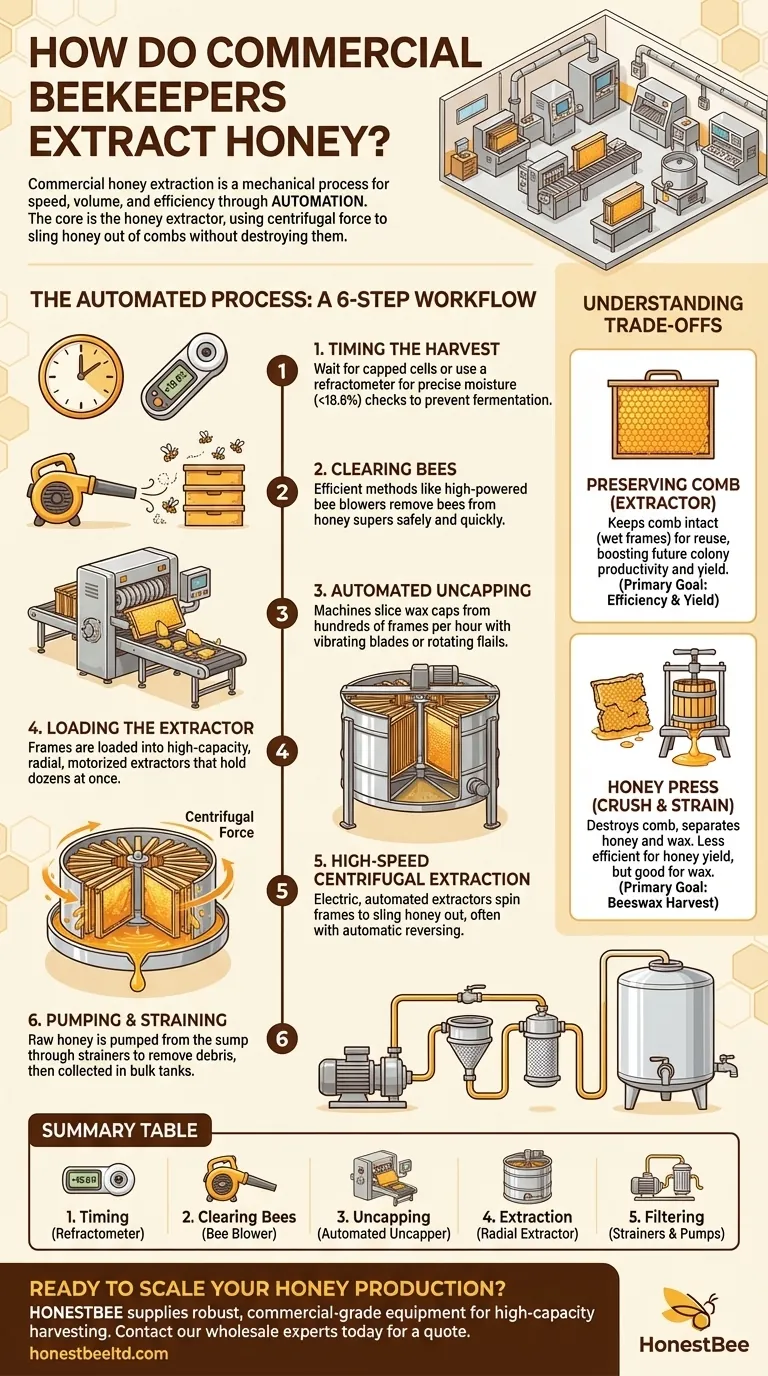

At its core, commercial honey extraction is a mechanical process centered on a machine called a honey extractor. This device uses centrifugal force to sling liquid honey out of the beeswax combs without destroying them. For commercial beekeepers, the entire workflow—from removing bees from the hives to bottling the final product—is optimized for speed, volume, and efficiency through automation.

The key difference between hobbyist and commercial honey extraction is not the principle but the scale. Commercial operations rely on automated, high-capacity equipment to process thousands of pounds of honey, minimizing manual labor and maximizing the preservation of valuable honeycomb for reuse.

The Pre-Extraction Phase: Preparing for Harvest

Before any honey enters a bottle, beekeepers must ensure it's ready for collection and that the hives are prepared for the intrusion. This initial phase is critical for quality and efficiency.

Step 1: Timing the Harvest

A premature harvest yields honey with excessive moisture, which can ferment and spoil. Commercial beekeepers use two key indicators to know when honey is ready.

First, they visually inspect the frames. Bees will place a wax capping over each cell of honey once the water content has been reduced to the ideal level, which is a sign it's cured and ready.

Second, for precise quality control, many use a refractometer. This tool measures the exact moisture content of the honey, ensuring it is typically below 18.6% to be stable for long-term storage.

Step 2: Clearing Bees from the Honey Supers

The "honey supers" are the boxes on top of the hive where bees store their excess honey. To harvest them, beekeepers must first remove the thousands of bees inside.

Commercial operations use efficient methods like bee blowers, which are essentially high-powered leaf blowers that safely push the bees out of the supers. Other methods include using chemical repellent boards or one-way "bee escape" boards that let bees leave the super but not re-enter.

The Core of Commercial Extraction: The Automated Process

Once the bee-free honey supers are transported to the extraction facility, the high-volume mechanical process begins.

Step 3: Uncapping the Honeycomb

The protective wax caps on the honeycomb must be removed. While a hobbyist might use a simple heated knife, commercial facilities use automated uncapping machines.

These machines use vibrating blades, heated knives, or rotating flails to slice off the cappings from hundreds of frames per hour, dropping the frames onto a conveyor for the next stage.

Step 4: Loading the Extractor

The uncapped frames are then placed into a large, motorized honey extractor. These are typically radial extractors, where frames are arranged like spokes in a wheel.

Commercial models can hold dozens of frames at once, a significant increase from the 2-4 frame capacity of a manual, hand-cranked extractor used by hobbyists.

Step 5: High-Speed Centrifugal Extraction

Once loaded, the machine spins the frames at high speed. The centrifugal force slings the honey outward against the extractor's inner wall, where it drips down to a collection sump at the bottom.

Electric and automated extractors are the industry standard. They control the spin speed and duration, often reversing direction automatically to ensure all honey is extracted from both sides of the comb. This automation is vital for reducing labor and increasing productivity.

Step 6: Pumping and Straining

From the extractor's sump, the raw honey is pumped through a series of strainers or filters. This process removes any remaining bits of beeswax, bee parts, or other debris. The resulting clean honey is then collected in large tanks or barrels for storage before bottling.

Understanding the Trade-offs: Extraction vs. Other Methods

While centrifugal extraction is dominant, it's important to understand why it's the preferred method for producing liquid honey.

The Power of Preserving Comb

The primary advantage of a honey extractor is that it keeps the honeycomb structure intact. After extraction, these "wet frames" can be returned to the hives.

Bees expend a tremendous amount of energy and resources to build beeswax comb. By reusing the comb, beekeepers give their colonies a massive head start, allowing them to focus on gathering nectar and producing more honey far more quickly.

The Role of a Honey Press

An alternative method is using a honey press, which works by crushing the entire comb and squeezing the honey out. This method, known as crush and strain, is simple but destructive.

Because it destroys the comb, it is far less efficient for beekeepers focused on maximizing honey production year after year. It is more commonly used for producing blocks of comb honey or when the primary goal is to harvest beeswax alongside the honey.

Making the Right Choice for Your Goal

Understanding the extraction process provides insight into the different types of honey products available.

- If your primary focus is efficiency and yield: Centrifugal extraction is the only viable commercial method because it preserves the comb, which is a critical asset for future production.

- If your primary focus is harvesting beeswax: The crush and strain method using a press is effective, as it separates both honey and wax for processing.

- If your primary focus is producing "comb honey": The entire extraction process is bypassed, and sections of the sealed honeycomb are simply cut from the frame and packaged.

Ultimately, the commercial honey extraction process is a masterclass in industrial efficiency, designed to produce a pure, stable product at scale while supporting the bees' natural productivity.

Summary Table:

| Step | Process | Key Commercial Equipment |

|---|---|---|

| 1. Timing | Check honey readiness | Refractometer |

| 2. Clearing Bees | Remove bees from honey supers | Bee Blower |

| 3. Uncapping | Remove wax caps from frames | Automated Uncapping Machine |

| 4. Extraction | Spin honey out of frames | Radial Honey Extractor |

| 5. Filtering | Remove debris from raw honey | Strainers & Pumps |

Ready to Scale Your Honey Production?

As a commercial beekeeper or equipment distributor, maximizing efficiency is key to your profitability. HONESTBEE supplies the robust, high-capacity beekeeping equipment you need—from commercial-grade honey extractors and uncappers to bee blowers—to streamline your entire harvest operation.

Let us help you increase your yield and reduce labor costs. Contact our wholesale experts today to discuss your operation's needs and get a quote.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- Which type of extractor is better for medium to large-scale honey processing? Boost Efficiency with Electric Radial Extractors

- What should a beekeeper do after extracting honey from supers? A Guide to Harvest Management

- What are the main types of honey extractors? Choose the Right Model for Your Apiary

- What are the advantages of automated honey extractors in terms of time efficiency? Boost Your Harvest Speed

- What are the two common types of honey extractors? Choose the Right Extractor for Your Apiary