At its core, a honey filling machine automates the process of dispensing a precise amount of honey into containers. It operates through a coordinated system that moves containers, fills them using a specific mechanism suited for honey's thick consistency, and then seals them for distribution. The most common and effective mechanism for this task is the piston filler, which acts like a large, precise syringe to handle the viscous nature of honey.

The central challenge in packaging honey is managing its high viscosity. Therefore, the effectiveness of a honey filling machine is defined by its filling mechanism, with piston-based systems being the industry standard for ensuring an accurate, consistent, and clean fill every time.

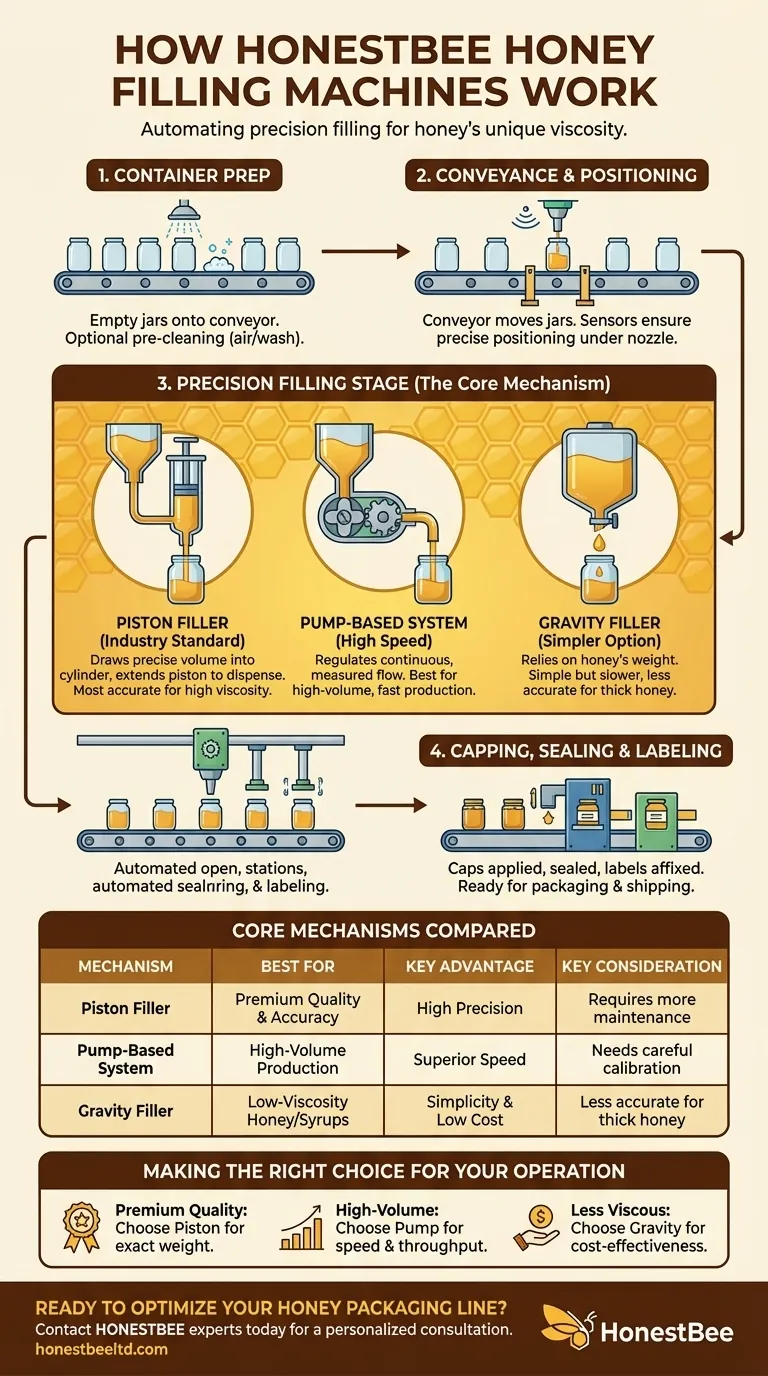

The Step-by-Step Packaging Journey

A honey filling machine is more than just a dispenser; it's typically part of an integrated production line. The process follows a logical sequence from an empty jar to a market-ready product.

Container Handling and Preparation

The process begins with empty containers being placed onto a conveyor. This can be done manually by an operator or automatically by a machine depending on the scale of the operation. In some systems, an auxiliary station may pre-clean the jars with air or a wash cycle.

Conveyance to the Filling Station

Once on the line, containers are moved by a conveyor belt to the filling station. Sensors and guides ensure the jars are positioned perfectly under the filling nozzle to prevent spills and ensure a centered fill.

The Precision Filling Stage

This is the most critical step. The machine dispenses a predetermined volume of honey into each container. The honey is typically held in a large hopper and fed to the filling mechanism by gravity or a pump to ensure a continuous supply.

Capping, Sealing, and Labeling

After being filled, the containers move along the conveyor to subsequent stations. Here, caps are applied and sealed, and labels are affixed. The finished product is then ready for packaging and shipping.

The Core Filling Mechanisms Explained

The heart of the machine is its filling mechanism. The choice of technology is dictated by honey's unique properties, primarily its thickness or viscosity.

Piston Fillers: The Standard for Viscosity

A piston filler is the most common choice for honey. It operates by drawing a precise volume of honey from a hopper into a cylinder as the piston retracts. Then, as the piston extends, it pushes that exact amount of honey out through the nozzle and into the jar.

This method is exceptionally accurate and consistent, making it ideal for thick products where flow can be difficult to control.

Pump-Based Systems: The Choice for Speed

For high-volume, high-speed operations, pump-based systems are often used. These machines use various types of pumps (like lobe or gear pumps) to regulate a continuous, measured flow of honey into the containers. While very fast, they must be carefully calibrated to match the viscosity of the honey.

Gravity and Vacuum Fillers: Situational Alternatives

Gravity fillers rely on the weight of the honey in an overhead tank to fill containers below. This method is simpler and works well for low-viscosity liquids, but it can be slow and less accurate for thick honey.

Vacuum fillers create a vacuum seal on the container, which then draws the honey in from a reservoir. This is less common but can be effective for specific container types.

Understanding the Trade-offs

Choosing the right technology involves balancing accuracy, speed, and complexity. Each filling mechanism comes with its own set of advantages and disadvantages.

Piston Fillers: Accuracy vs. Mechanical Complexity

The primary benefit of a piston filler is its unparalleled accuracy. However, these systems have more moving parts (pistons, cylinders, seals), which can require more intensive cleaning and maintenance compared to simpler systems.

Pump Systems: Speed vs. Product Handling

Pump systems offer superior speed for large-scale production. The trade-off is that some pump designs can be more aggressive on the product, potentially introducing air or altering its texture if not configured correctly for the specific type of honey.

Gravity Fillers: Simplicity vs. Limited Application

The main advantage of gravity fillers is their simplicity and low cost. Their significant disadvantage is a lack of precision and speed when dealing with highly viscous products like honey, making them unsuitable for most professional honey packing operations.

Making the Right Choice for Your Operation

Selecting the appropriate machine depends entirely on your production goals, the type of honey you process, and your budget.

- If your primary focus is premium quality and accuracy: A piston filler is the superior choice, ensuring every jar meets exact weight specifications.

- If your primary focus is high-volume industrial production: A carefully calibrated pump-based system will deliver the speed and throughput you need.

- If you are working with less viscous honey or honey-based syrups: A simpler gravity filler might be a cost-effective solution for your needs.

Ultimately, understanding these core mechanics empowers you to select a system that preserves your honey's quality while meeting your production demands.

Summary Table:

| Filling Mechanism | Best For | Key Advantage | Key Consideration |

|---|---|---|---|

| Piston Filler | Premium Quality & Accuracy | High Precision | Requires more maintenance |

| Pump-Based System | High-Volume Production | Superior Speed | Needs careful calibration |

| Gravity Filler | Low-Viscosity Honey/Syrups | Simplicity & Low Cost | Less accurate for thick honey |

Ready to Optimize Your Honey Packaging Line?

At HONESTBEE, we specialize in supplying robust, high-performance honey filling machines and beekeeping equipment to commercial apiaries and distributors. Our solutions are designed to handle the unique viscosity of honey, ensuring precise fills, reduced waste, and increased throughput for your wholesale operations.

Let us help you select the perfect filling system for your needs. Contact our experts today for a personalized consultation and discover how HONESTBEE can enhance your productivity and product quality.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

People Also Ask

- How does specialized honey extraction and filling machinery contribute to quality? 3 Key Ways to Preserve Purity

- How does honey get packaged? Preserve Quality and Boost Appeal

- What precautions should be taken when packing honey? Ensure Quality from Hive to Jar

- What is the indirect impact of automated hive-making and honey-filling machines on the pollination market? Boost Stability

- How does the speed of automatic filling machines compare to manual filling? Unlock Mass Production Potential

- What is a semi-automatic honey filler? Scale Your Honey Production with Precision and Efficiency

- How do automatic honey filling and capping machines improve the profitability of beekeeping enterprises?

- What is the industrial value of professional honey filling and processing machinery? Maximize Your Market Value