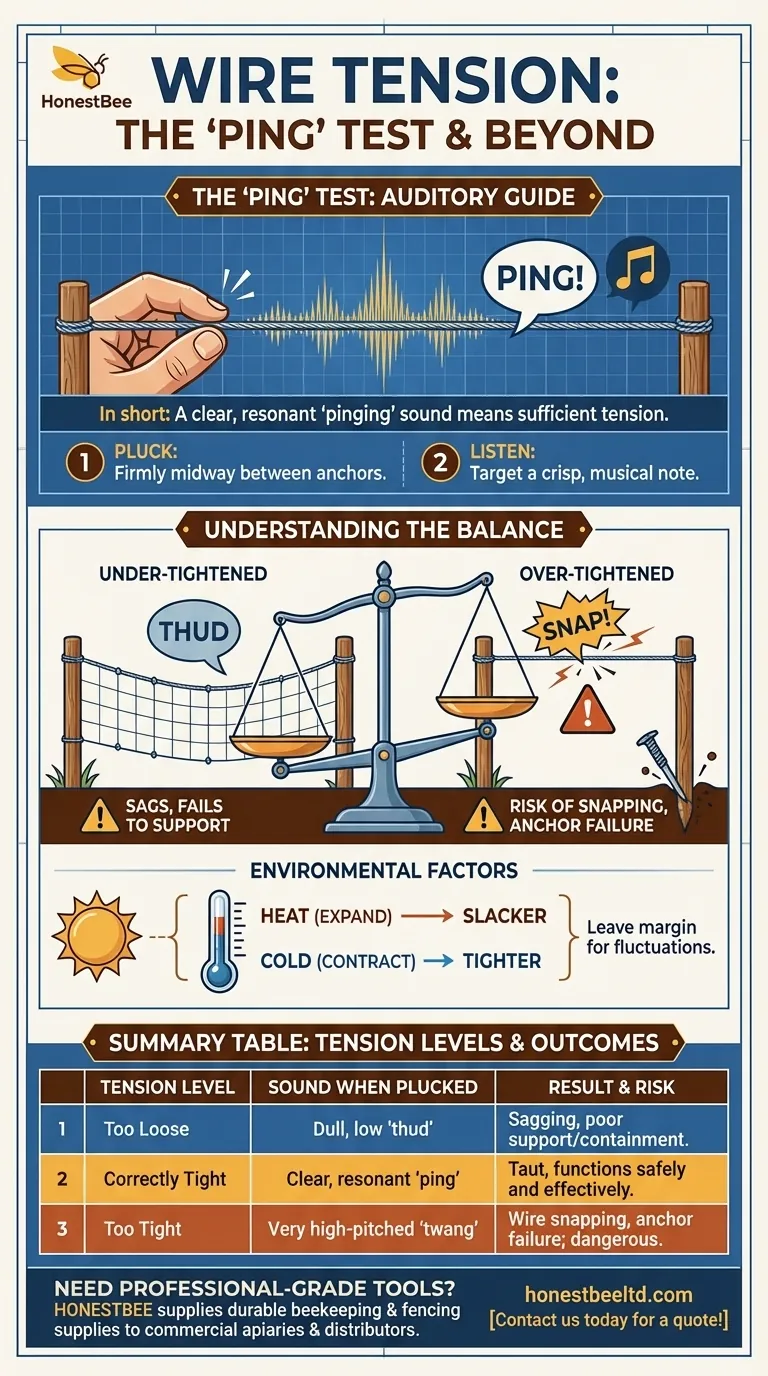

In short, the wire is sufficiently tight when it emits a clear, resonant "pinging" sound when plucked. This auditory feedback is a reliable field test indicating that the slack has been removed and the wire is now under proper tension. A loose wire will produce a dull, low-pitched "thud" with little to no resonance.

The core principle is using sound as a simple proxy for tension. While the "ping" test is an excellent qualitative guide, the precise amount of tension required is ultimately dictated by the wire's material, its intended purpose, and the structural integrity of its anchor points.

The "Ping" Test: Your Auditory Guide

The most accessible method for gauging wire tension doesn't require specialized tools. It relies on the direct relationship between tension and the frequency of vibration, which you can easily hear.

What to Listen For

A wire with insufficient tension will feel limp and produce a low, dull sound when struck or plucked. As you tighten the wire, this sound will evolve. The target is a clear, crisp, and almost musical note—a "ping." This higher frequency indicates the wire is taut and vibrating correctly.

How to Perform the Test

Midway between the anchor points, pluck the wire firmly with your thumb and forefinger, then listen. The goal is not to produce a specific musical note, but to hear that distinct transition from a dull thud to a sharp ping.

Why This Works

This method is a simple application of physics. Just like a guitar string, a wire's vibrational frequency (its pitch) increases with tension. The "ping" is simply your ear detecting that the wire has reached a high enough tension to vibrate rapidly and produce a high-frequency sound wave.

Understanding the Trade-offs

Achieving the right tension is a balancing act. Both under-tightening and over-tightening introduce significant problems and potential dangers.

The Risk of Under-Tightening

An under-tightened wire will sag under its own weight or when a load is applied. For applications like fencing, this compromises its core function, allowing livestock to push through or vegetation to weigh it down. For guide wires, it means a lack of structural support.

The Critical Danger of Over-Tightening

This is the more serious error. An over-tightened wire is under immense strain. This can lead to two primary failure points:

- Wire Failure: The wire itself can snap, releasing a tremendous amount of stored energy. A snapping high-tensile wire is incredibly dangerous and can cause serious injury.

- Anchor Failure: The tension can place excessive force on your anchor posts, brackets, or connections, causing them to bend, break, or pull out of the ground over time.

Accounting for Environmental Factors

Remember that metal expands in the heat and contracts in the cold. A wire tightened to its absolute maximum on a cool day may snap as it gets hotter. Conversely, a wire that seems perfectly tight on a hot day will become noticeably slacker in colder weather. It's often wise to leave a small margin for these fluctuations.

Making the Right Choice for Your Goal

Use your application's purpose to determine how rigorously you should apply the tension test.

- If your primary focus is a non-structural guide (e.g., a simple garden trellis): The "ping" test is a perfect indicator; the main goal is simply removing visible sag.

- If your primary focus is structural integrity (e.g., farm fencing, bracing): Use the "ping" test as your baseline, then carefully inspect your anchor posts for any signs of bowing or strain.

- If your primary focus is high-precision loading (e.g., guy wires for a tower): The auditory test is insufficient; you must use a specialized tension gauge to meet engineering specifications.

Ultimately, proper tension ensures your wire performs its job effectively and safely for years to come.

Summary Table:

| Tension Level | Sound When Plucked | Result & Risk |

|---|---|---|

| Too Loose | Dull, low 'thud' | Wire will sag; fails to support or contain. |

| Correctly Tight | Clear, resonant 'ping' | Wire is taut; functions safely and effectively. |

| Too Tight | Very high-pitched 'twang' | Risk of wire snapping or anchor failure; dangerous. |

Need the right tools for safe and effective wire installation?

HONESTBEE supplies professional-grade beekeeping and fencing supplies to commercial apiaries and distributors. Ensure your projects are built to last with our durable equipment. Get in touch with our experts for wholesale inquiries and elevate your operations.

Visual Guide

Related Products

- HONESTBEE Durable Ergonomic Wooden Handle Frame Wire Crimper

- HONESTBEE AC Powered Wire Embedder with Alligator Clips

- Honestbee Wooden Handle Steel Spur Wheel Wire Embedder

- HONESTBEE Ergonomic Spring Loaded Frame Wire Crimper

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- What frame materials are compatible with the cell punch method? Essential Guide for Successful Queen Rearing

- What are some tips for setting up hive frames? Build a Strong Foundation for Your Hive

- What role do small compression springs play within a capacitive beehive frame weight sensor? Key Mechanics Explained

- What are frames and foundation within a beehive? Essential Guide to Modern Hive Architecture

- What are the advantages of using movable frame hives for Varroa mite diagnostic surveys? Enhancing Precision in Beekeeping

- How many frames should be placed in a 10-frame box? Optimize Your Hive for Growth & Harvest

- How does a Modified Langstroth frame with grid lines facilitate measurement? Precision Tracking for Brood Analysis

- What is a Frame Assembly Jig and what is its purpose? Boost Your Beekeeping Efficiency and Accuracy