A honey filling machine fundamentally improves your packaging process by replacing manual labor with automated precision. This shift allows you to dispense honey into containers with exceptional accuracy and speed, which significantly boosts productivity, ensures a consistent product for your customers, and minimizes costly spillage and waste.

The true value of a honey filling machine is not just about filling jars faster. It is about introducing a system of control, scalability, and professionalism into your operation that is impossible to achieve with manual methods alone.

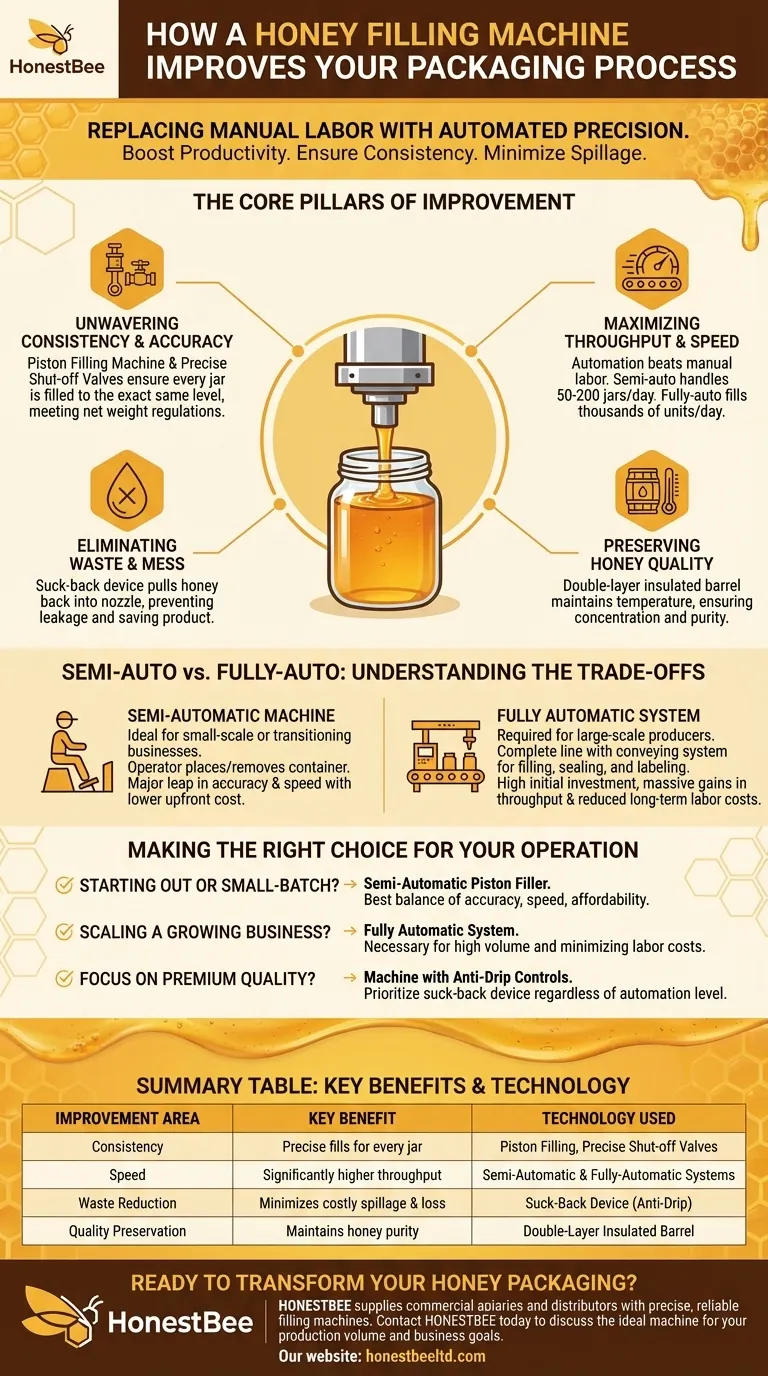

The Core Pillars of Improvement

A honey filling machine addresses the three primary challenges of packaging a viscous product like honey: consistency, speed, and waste. It transforms these challenges into operational strengths.

Achieving Unwavering Consistency and Accuracy

The most common technology, a piston filling machine, uses a piston moving within a cylinder to draw in and dispense a precise, repeatable volume of honey. This mechanical action ensures every jar is filled to the exact same level.

More advanced systems use precise shut-off valves at the nozzle to instantly stop the flow, preventing overfills. This consistency is critical for brand reputation and meeting net weight regulations.

Maximizing Throughput and Speed

Automation is the key to scaling your output. While manual filling is limited by operator fatigue and dexterity, a machine provides stable, continuous performance.

Even a semi-automatic machine can significantly outpace a human, handling anywhere from 50 to 200 jars per day. Fully automatic systems with multiple nozzles can fill, cap, and label thousands of units per day.

Eliminating Product Waste and Mess

Honey's viscosity makes clean cutoffs difficult in a manual process, leading to drips, mess, and lost product.

Machines solve this with features like a suck-back device, which pulls a small amount of honey back into the nozzle after each fill. This prevents leakage and ensures both your containers and your workspace remain clean, directly saving money on lost product.

Preserving Honey Quality

Specialized honey packaging machines often include features designed to protect the product itself.

A double-layer insulated barrel helps maintain the honey at a consistent temperature. This ensures its concentration and purity are not compromised during the packaging process, regardless of how long the production run is.

Understanding the Trade-offs: Semi-Auto vs. Fully-Auto

Choosing the right machine is not a one-size-fits-all decision. The primary trade-off is between the upfront cost and the level of automation, which is directly tied to your production volume.

The Role of a Semi-Automatic Machine

A semi-automatic machine requires an operator to place the container, initiate the fill (often with a foot pedal), and then remove the filled container.

These machines are ideal for small-scale producers or businesses transitioning from manual methods. They offer a major leap in accuracy and speed over hand-pouring without the capital expense of a fully integrated line.

The Power of a Fully Automatic System

A fully automatic system is a complete packaging line. It uses a conveying system to move containers through every stage: filling, sealing, and labeling, with minimal human intervention.

This is the required solution for large-scale producers. The high initial investment is offset by massive gains in throughput and a significant reduction in long-term labor costs per unit.

Key Factors Influencing Your Choice

Your decision should be based on an objective analysis of your needs. Consider your current and projected production volume, the types of containers you use (glass jars, plastic bottles, pouches), and your long-term business goals.

Making the Right Choice for Your Operation

To select the appropriate machine, align the technology with your primary operational goal.

- If your primary focus is starting out or small-batch production: A semi-automatic piston filler offers the best balance of accuracy, speed, and affordability.

- If your primary focus is scaling a growing business: A fully automatic system is a necessary investment for achieving high volume and minimizing long-term labor costs.

- If your primary focus is premium quality and presentation: Prioritize a machine with precise anti-drip controls like a suck-back device, regardless of the level of automation.

Ultimately, investing in the right filling machine allows you to focus less on the labor of packaging and more on the business of producing great honey.

Summary Table:

| Improvement Area | Key Benefit | Technology Used |

|---|---|---|

| Consistency | Precise fills for every jar, meeting net weight regulations | Piston Filling, Precise Shut-off Valves |

| Speed | Significantly higher throughput vs. manual filling | Semi-Automatic & Fully-Automatic Systems |

| Waste Reduction | Minimizes costly spillage and product loss | Suck-Back Device (Anti-Drip) |

| Quality Preservation | Maintains honey purity during long runs | Double-Layer Insulated Barrel |

Ready to transform your honey packaging?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the precise, reliable honey filling machines they need to scale operations and maximize profitability. Our wholesale-focused solutions are engineered to boost your efficiency, ensure product consistency, and significantly reduce waste.

Contact HONESTBEE today to discuss the ideal filling machine for your production volume and business goals.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Automated Rotary Bottle Unscrambler for Honey Production Line

People Also Ask

- What technical advantages do precision honey filling machines provide? Optimize Your Honey Packaging Workflow

- How do automatic honey filling machines contribute to the value addition of commercial honey? Boost Brand Consistency

- What is the primary function of a semi-automatic dosing machine? Optimize Your Honey Filling Precision

- What are the benefits of using high-precision honey-filling machines? Boost ROI & Quality in Commercial Honey Production

- What contribution does automatic honey filling and processing machinery make to the honey industry's value enhancement?

- What core processing challenges are addressed by automated honey-filling machines? Boost Your Honey Production Now

- How does industrial honey filling and processing machinery aid colony management? Optimize Yield & Data Intelligence

- Why are industrial honey-filling machines essential? Scale Your Production with Safety and Precision