At its core, a honey heating tank preserves the quality of honey not just by warming it, but by doing so with exceptional control. It uses gentle, consistent heat to make honey workable without degrading its delicate enzymes, flavors, and nutritional compounds, which are easily damaged by conventional, uncontrolled heating methods.

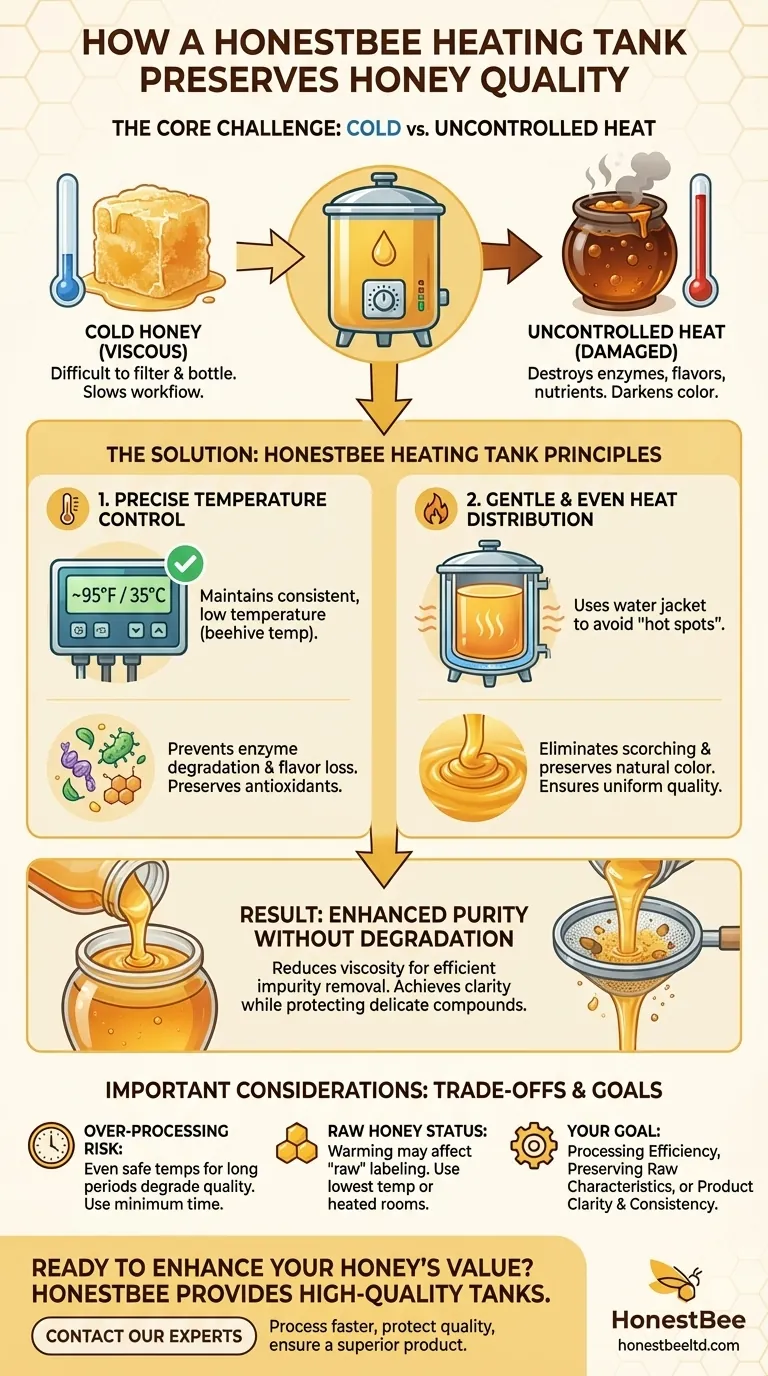

The fundamental challenge in honey processing is balancing two opposing needs: the need for heat to make viscous honey flow, and the need to avoid heat to preserve its natural quality. A proper heating tank is the critical tool that resolves this conflict by providing just enough warmth, precisely controlled.

The Challenge: Why Honey Requires Special Handling

Before understanding the solution, we must appreciate the problem. Honey in its natural, crystallized, or cool state presents significant processing challenges, but the wrong solution can be worse than the problem itself.

The Problem with Cold Honey

Raw, cool honey is extremely viscous. This thickness makes essential tasks like filtering, straining, and bottling incredibly difficult and time-consuming.

Without gentle warming, processors face slow workflows, inconsistent results, and the inability to effectively remove fine impurities like wax particles.

The Danger of Uncontrolled Heat

Honey is a sensitive biological product. When overheated, it undergoes irreversible damage.

Excessive or uneven heat destroys beneficial enzymes like diastase and invertase, darkens the honey's color, and can caramelize its natural sugars, permanently altering its delicate flavor and aroma. This degradation effectively strips the honey of its unique, high-value characteristics.

How a Heating Tank Preserves Honey's Integrity

A honey heating tank is engineered specifically to navigate the fine line between workability and degradation. It relies on two core principles to protect the honey's quality.

Principle 1: Precise Temperature Control

The most critical feature is a reliable thermostat. These tanks are designed to maintain a specific, low temperature without fluctuation.

Many operators aim to keep the honey at a temperature similar to that inside a natural beehive (around 95°F or 35°C). This provides enough fluidity for processing while staying well below the threshold where damage begins to occur, preserving its natural antioxidants and enzymes.

Principle 2: Gentle and Even Heat Distribution

Heating tanks avoid "hot spots" that can scorch and ruin the honey. Most high-quality tanks use a water jacket design.

In this system, a separate chamber of water is heated, and this warm water then surrounds the inner tank holding the honey. This method transfers heat indirectly and evenly, ensuring no part of the honey is exposed to dangerously high temperatures.

Consequence: Enhanced Purity Without Degradation

By gently lowering the honey's viscosity, a heating tank allows it to pass through filters more easily and efficiently.

This enables the effective removal of impurities such as wax, bee parts, and other debris. The result is a clearer, more visually appealing final product that has not been compromised by excessive heat.

Understanding the Trade-offs and Risks

While a heating tank is a vital tool, its use requires knowledge and care. It is not a magic bullet, and improper use can still harm the honey.

The Risk of Over-processing

Temperature is only one factor; time is the other. Even honey held at a safe, low temperature for an extended period (days instead of hours) can begin to show signs of degradation.

The goal should always be to heat the honey for the minimum time necessary to complete the filtering and bottling process.

The Impact on "Raw" Honey Status

The term "raw honey" typically implies the honey has not been heated. While definitions vary, heating honey above beehive temperatures may disqualify it from being labeled "raw" by certain standards.

Producers aiming for a certified raw product must use extreme care, warming the honey to the lowest possible temperature or using alternative methods like a heated room to gently liquefy it in its storage containers.

Making the Right Choice for Your Goal

A honey heating tank is an investment in quality and efficiency. How you use it depends entirely on your end goal.

- If your primary focus is processing efficiency: The tank is essential for creating a smooth, fast workflow from extraction to bottling, allowing you to filter and package honey effectively.

- If your primary focus is preserving raw characteristics: Use the tank at the lowest possible temperature for the shortest possible time, or consider warming entire buckets in a heated room as a less direct alternative.

- If your primary focus is product clarity and consistency: A heating tank is invaluable for achieving a uniform, impurity-free product that meets consumer expectations for visual appeal.

Ultimately, using a honey heating tank is about applying technology thoughtfully to honor and preserve the honey's natural perfection.

Summary Table:

| Key Feature | Function | Benefit to Honey Quality |

|---|---|---|

| Precise Temperature Control | Maintains a consistent, low temperature (e.g., ~95°F/35°C). | Prevents enzyme degradation and flavor loss. |

| Gentle, Even Heat Distribution | Uses a water jacket to avoid hot spots. | Eliminates scorching and preserves natural color. |

| Enhanced Filtration | Reduces viscosity for efficient impurity removal. | Achieves clarity without compromising nutritional value. |

Ready to enhance your honey's purity and value?

As a leading supplier to commercial apiaries and distributors, HONESTBEE provides high-quality honey heating tanks designed for precision and efficiency. Our equipment helps you process honey faster while protecting its delicate enzymes and flavor profile, ensuring a superior product for your customers.

Contact our experts today to find the perfect heating solution for your operation and learn about our full range of beekeeping supplies.

Visual Guide

Related Products

- Stainless Steel Heated Honey Tank Warming Heating Tank

- Professional Honey Storage Tank with Agitation System

- Stainless Steel Uncapping Tank with Stand and Strainer

- Stainless Steel Honey Storage and Settling Tank with Double Strainer

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What are the practical benefits of using a honey bucket warmer? Ensure Quality & Efficiency in Your Apiary

- What is the purpose of heating honey during processing? Optimize Flow, Filtration, and Shelf Stability Efficiently

- Why is a controlled-temperature drying oven required for raw beeswax combs? Maintain Purity and Quality

- What is the best way to liquify honey? Preserve Flavor and Nutrients with Gentle Heat

- What makes honey heating tanks versatile? Adapt to Any Honey Type and Scale Your Production

- How does a honey heating tank help in preserving the quality of honey? Expert Guide to Protecting Enzymes & Flavor

- Why is the use of controlled heating equipment necessary when analyzing crystallized honey samples? Ensure Accuracy

- Why is electronic constant temperature drying equipment required for drone brood powder? Ensure Quality and Efficiency