The primary advantage of a double sieve is its two-stage filtration system, which dramatically improves both the efficiency and the quality of the process. The top, coarser sieve acts as a pre-filter, catching large debris like wax cappings and bee parts. This prevents the bottom, finer sieve from clogging, allowing it to effectively remove smaller particles for a much cleaner final product.

The core principle behind the double sieve is not just filtration, but staged filtration. By separating the task into two distinct steps—bulk removal followed by fine polishing—it solves the clogging problem inherent in single-sieve systems, allowing for a faster and more thorough purification of honey.

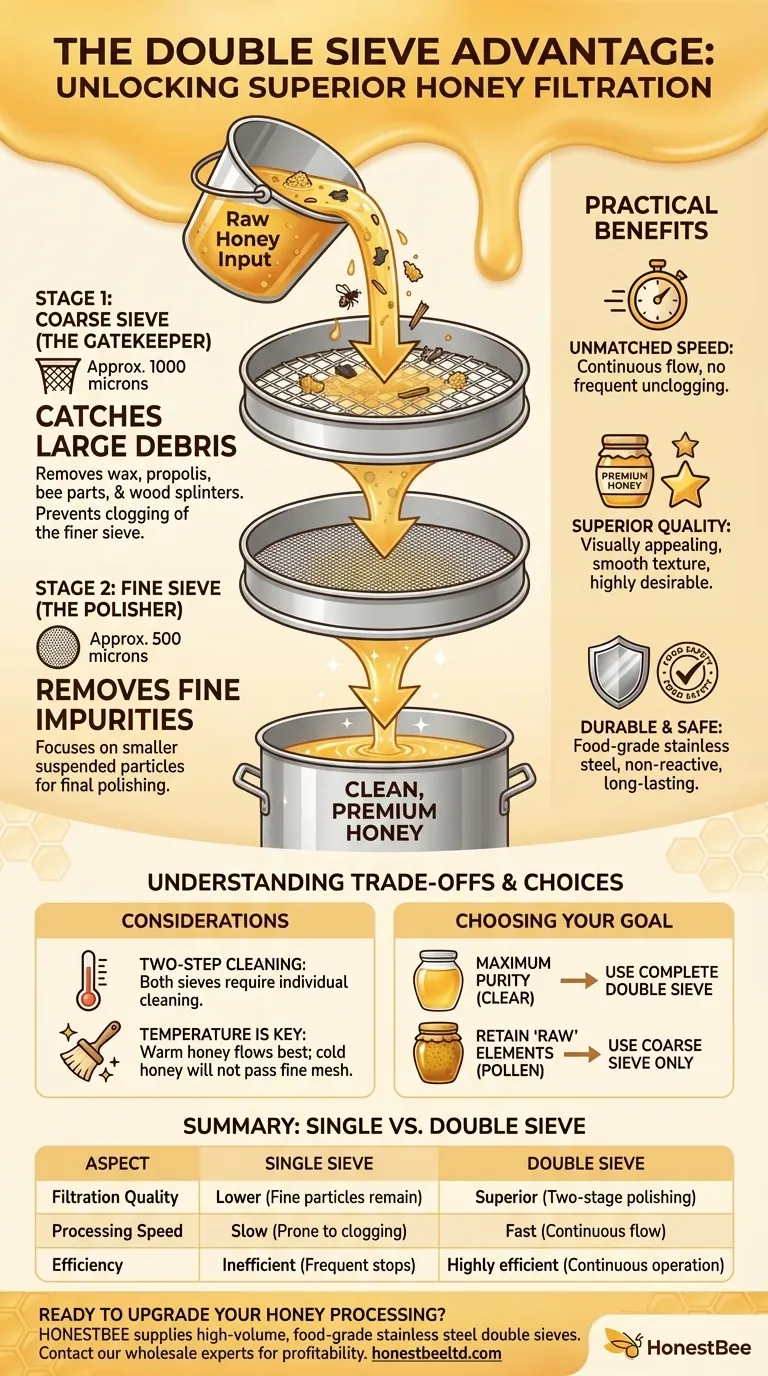

The Principle of Staged Filtration

A double sieve is more than just two filters stacked together; it's an engineered solution to a common bottleneck in honey processing. The entire system is designed to work in sequence, with each stage preparing the honey for the next.

The Coarse Sieve: The Gatekeeper

The top layer is a coarse mesh (often around 1000 microns). Its sole job is to catch the "heavy lifters" of debris.

This includes larger pieces of beeswax, propolis, wood splinters from the hive, and any unfortunate bees. By removing these large items first, it does the vast majority of the filtering work.

The Fine Sieve: The Polisher

Sitting directly below is the fine mesh (often around 500 microns). Its purpose is to perform the final polishing.

Because the top sieve has already removed the large, clog-prone debris, this finer layer can focus on removing smaller suspended particles. This results in the exceptionally clean, light-colored, and smooth-textured honey that customers value.

Why a Single Sieve is Inefficient

Using a single fine-mesh sieve would be incredibly slow. The large pieces of wax would quickly block the small openings, forcing you to constantly stop and clear the filter.

Conversely, using only a single coarse sieve would be fast but would leave many fine impurities in the honey, resulting in a lower-quality product. The double sieve provides the best of both worlds.

The Practical Benefits of the Double Sieve Design

Beyond the core principle, the typical design of a double sieve offers several practical advantages for the beekeeper.

Unmatched Processing Speed

By preventing clogs, the double sieve allows you to process a large volume of honey continuously. This significantly speeds up your workflow during the busy extraction season.

Superior Honey Quality

The two-stage process guarantees a consistently pure product. The resulting honey is visually appealing, free of debris, and has a smooth mouthfeel, making it more desirable for bottling and selling.

Durable and Food-Safe Construction

Most double sieves are made from food-grade stainless steel. This material is critical because it is non-reactive, meaning it won't alter the taste or chemical composition of the honey.

Furthermore, stainless steel is highly durable, rust-resistant, and easy to clean and sanitize, ensuring safe honey handling for years. Many models also include extendable arms that allow them to rest securely over a variety of buckets and bottling tanks.

Understanding the Trade-offs

While highly effective, it's important to understand the context and limitations of using a double sieve system.

Cleaning is a Two-Step Process

The design that makes a double sieve so effective also means you have two separate components to clean. The top sieve, in particular, will collect a significant amount of wax that needs to be scraped off and handled.

Honey Temperature is Crucial

Honey viscosity is highly dependent on temperature. Cold or crystallized honey will not pass through a fine mesh sieve. For best results, honey should be warm (at room temperature or slightly above) to flow easily through both filters.

The "Raw Honey" Debate

Extremely fine filters can sometimes remove beneficial pollen grains along with impurities. While the standard double sieve setup produces brilliantly clear honey, some producers prefer to use only the coarse sieve to retain more of these natural elements for a more "raw" final product.

Making the Right Choice for Your Goal

To apply this effectively, match your filtration method to your desired outcome.

- If your primary focus is producing crystal-clear honey for sale: Use the complete double sieve system as intended to achieve maximum purity and visual appeal.

- If your primary focus is creating a "raw" or minimally processed product: Consider using only the top, coarser sieve to remove large debris while retaining most of the pollen.

- If your primary focus is processing efficiency: Always ensure your honey is slightly warmed before straining to reduce its viscosity and speed up the flow.

Ultimately, the double sieve is a simple yet powerful tool that enables you to produce professional-quality honey with remarkable consistency.

Summary Table:

| Aspect | Single Sieve | Double Sieve |

|---|---|---|

| Filtration Quality | Lower (fine particles remain) | Superior (two-stage polishing) |

| Processing Speed | Slow (prone to clogging) | Fast (continuous flow) |

| Efficiency | Inefficient, frequent stops | Highly efficient, continuous operation |

| Best For | Minimal processing | Professional, high-quality bottling |

Ready to upgrade your honey yield and quality?

For commercial apiaries and distributors, the right equipment is key to profitability. HONESTBEE supplies durable, food-grade stainless steel double sieves and other essential beekeeping supplies designed for high-volume, efficient operations.

Contact our wholesale experts today to discuss how our equipment can streamline your honey processing and help you deliver a superior product to your customers.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Professional Stainless Steel Honey Filter with Support Handle

- Two-Stage Plastic Honey Filter for Buckets

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

People Also Ask

- How does automated honey filtration and filling machinery improve quality? Guard Your Apiary Against Pest Contamination

- What is the primary purpose of honey filters? Achieve Professional Clarity & Pure Honey Quality

- Why are dual filtration sieves used in honey processing? Balance Purity & Nutrition for Professional Honey Production

- What is better, a 100 or 200 micron filter? Find the Right Fit for Your Water System

- Why is filtering honey considered an essential step in honey processing? Ensure Quality and Commercial Viability