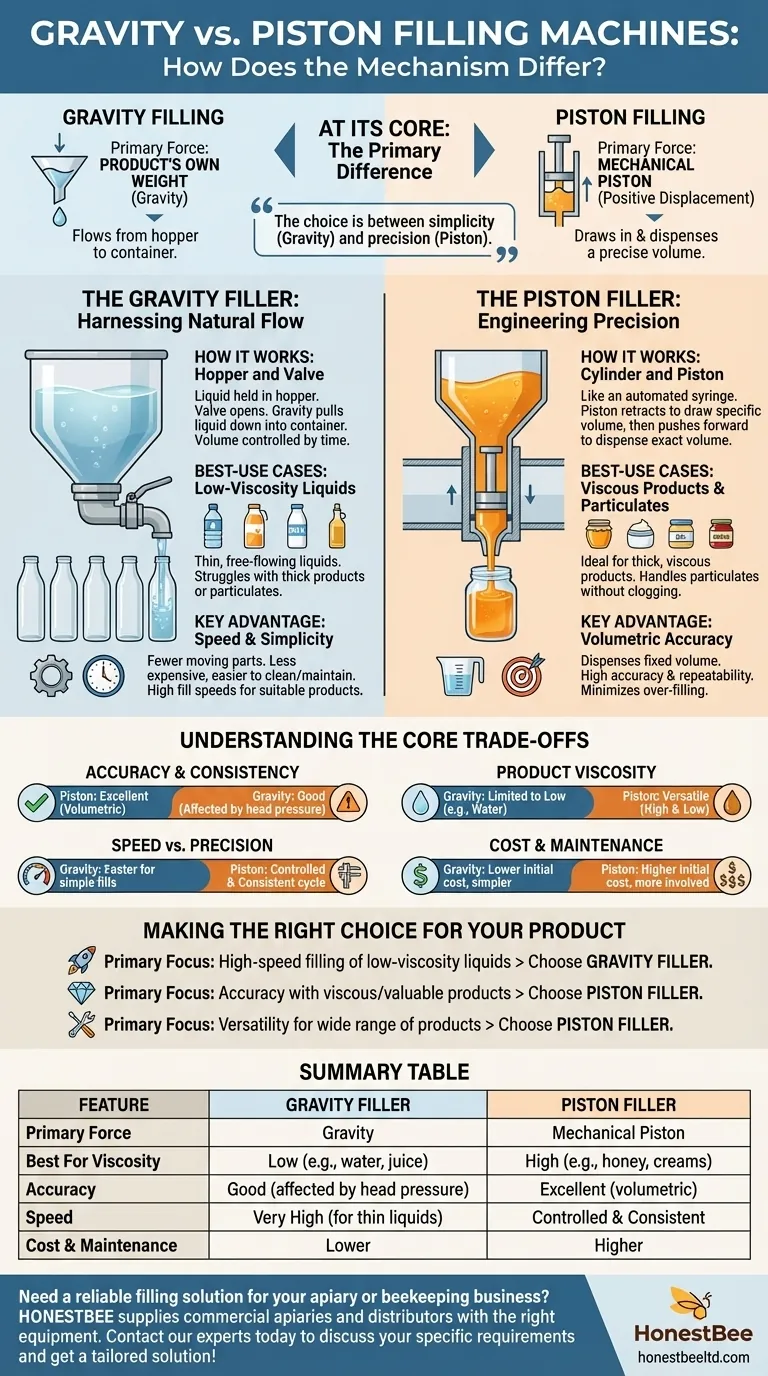

At its core, the primary difference lies in the force used to move the liquid. A gravity filling machine relies on the product’s own weight to flow from a hopper into a container, while a piston filling machine uses a mechanical piston to draw in and dispense a precise, measured volume. This fundamental distinction in mechanism dictates each machine's accuracy, speed, and suitability for different types of products.

The choice between gravity and piston filling is a decision between simplicity and precision. Gravity fillers excel at high-speed filling for thin, free-flowing liquids, whereas piston fillers deliver superior volumetric accuracy, making them essential for viscous, chunky, or high-value products.

The Gravity Filler: Harnessing Natural Flow

A gravity filler is the essence of simplicity. The machine’s design is straightforward, leveraging a principle we all understand.

How It Works: The Hopper and Valve

The liquid product is held in a hopper or tank positioned above the filling nozzles. When it's time to fill, a valve opens, and gravity pulls the liquid down into the container waiting below. The fill volume is typically controlled by timing the duration the valve stays open.

Best-Use Cases: Low-Viscosity Liquids

Gravity fillers are best suited for products that are thin and flow easily, like water, juices, milk, wine, and thin oils. They struggle with any product that is thick, viscous, or contains particulates, as gravity alone is not a strong enough force to ensure consistent flow.

Key Advantage: Speed and Simplicity

With fewer moving parts, gravity fillers are often less expensive, easier to clean, and simpler to maintain. For the right type of product, they can achieve very high fill speeds because the flow can be nearly continuous across multiple heads.

The Piston Filler: Engineering Precision

A piston filler operates on a principle of positive displacement, offering a much higher degree of control over the filling process.

How It Works: The Cylinder and Piston

Think of a piston filler as a large, automated syringe. A piston retracts within a cylinder, drawing a specific volume of product from the hopper. The piston then reverses direction, pushing forward to dispense that exact volume into the container.

Best-Use Cases: Viscous Products and Particulates

The mechanical force of the piston makes this filler ideal for thick, viscous products like honey, gels, creams, and heavy sauces. It can also effectively handle products with particulates, such as fruit preserves or salsas, that would clog a gravity filler.

Key Advantage: Volumetric Accuracy

Because it dispenses a fixed volume with each cycle, a piston filler provides extremely high accuracy and repeatability. This is critical when packaging valuable products, as it minimizes costly over-filling and ensures a consistent consumer experience.

Understanding the Core Trade-offs

Choosing the right machine requires a clear understanding of the trade-offs between these two mechanisms. Your product's characteristics and business priorities will determine the best fit.

Accuracy and Consistency

A piston filler is the clear winner for accuracy. It provides a true volumetric fill. A gravity filler's accuracy can be affected by changes in product temperature, viscosity, or the liquid level in the hopper (which alters the head pressure).

Product Viscosity

This is the most significant differentiator. Gravity fillers are limited to low-viscosity liquids. Piston fillers are far more versatile, capable of handling everything from water-thin liquids to thick pastes.

Speed vs. Precision

For simple fills with free-flowing liquids, a gravity filler can sometimes be faster. However, a piston filler’s cycle (draw and dispense) is highly controlled and consistent, often leading to better overall throughput when precision is a factor.

Cost and Maintenance

Gravity fillers are mechanically simpler, which generally makes them less expensive to purchase and maintain. The added complexity and precision of a piston filler—with its pistons, seals, and cylinders—typically result in a higher initial cost and more involved cleaning procedures.

Making the Right Choice for Your Product

Your decision ultimately depends on the nature of your product and your primary operational goals.

- If your primary focus is high-speed filling of low-viscosity liquids: A gravity filler offers a simple, fast, and cost-effective solution.

- If your primary focus is accuracy with viscous or valuable products: A piston filler provides the necessary control and consistency to protect your margins and ensure quality.

- If your primary focus is versatility to handle a wide range of product types: A piston filler is the more flexible choice, capable of managing everything from thin liquids to thick pastes.

By understanding these fundamental mechanics, you can select the technology that directly supports your production goals.

Summary Table:

| Feature | Gravity Filler | Piston Filler |

|---|---|---|

| Primary Force | Gravity | Mechanical Piston |

| Best For Viscosity | Low (e.g., water, juice) | High (e.g., honey, creams) |

| Accuracy | Good (affected by head pressure) | Excellent (volumetric) |

| Speed | Very High (for thin liquids) | Controlled & Consistent |

| Cost & Maintenance | Lower | Higher |

Need a reliable filling solution for your apiary or beekeeping business? HONESTBEE supplies commercial apiaries and distributors with the right equipment for their needs. Whether you're filling thin honey blends or thick, raw honey, we can help you select the perfect machine to ensure accuracy and protect your valuable product. Contact our experts today to discuss your specific requirements and get a tailored solution!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

People Also Ask

- How do high-precision honey-filling machines contribute to the incentive mechanisms for pollination services?

- How does the use of standardized honey filling machines contribute to brand building? Build Trust with Precision Filling

- What is the function of a twin honey stick machine? Double Your Honey Stick Production

- What production challenges are addressed by automated honey-filling machines? Boost Efficiency and Global Compliance

- Why are professional honey filling machines and specialized packaging consumables vital for quality control?

- What role do automated honey filling machines play in the commercial bee product distribution chain? Unlock Efficiency

- How do professional-grade honey-filling machines contribute to the economic efficiency of an apiary? Boost Your ROI

- What aspects contribute to the durability of a honey-filling machine? Maximize Longevity with Quality Builds