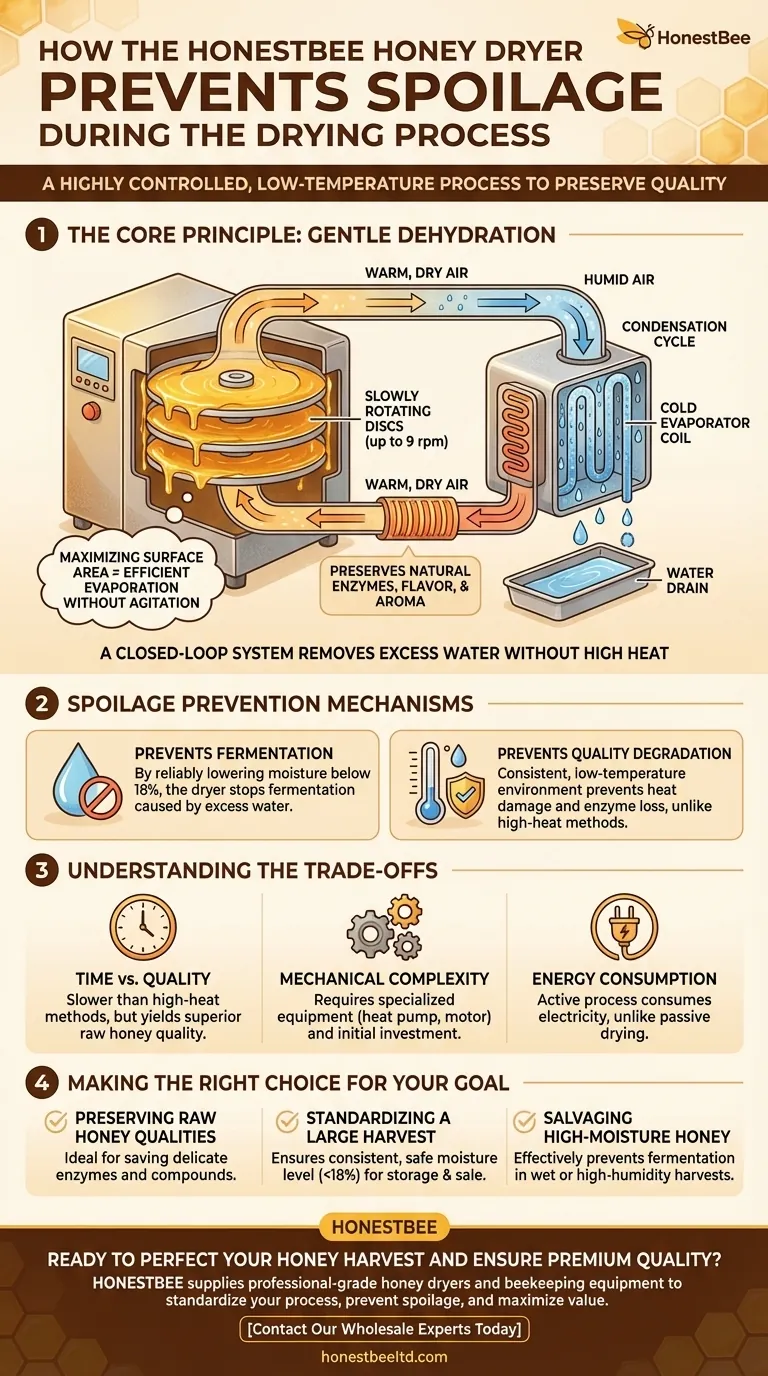

In short, a honey dryer prevents spoilage by using a highly controlled, low-temperature process. It combines the gentle movement of internal discs with a closed-loop system of warm, dry air to remove excess water. This method is specifically designed to dehydrate the honey without the high heat that would degrade its natural enzymes, delicate flavors, and aroma.

The central principle is not aggressive heating, but gentle persuasion. A honey dryer creates the perfect, controlled conditions to encourage water to evaporate from the honey without damaging its fundamental quality.

The Core Principle: Gentle Dehydration

Honey spoilage, in this context, refers to two primary risks: fermentation from excess water content and the degradation of its beneficial properties (like enzymes) from excessive heat. A honey dryer mitigates both risks through a sophisticated, yet gentle, process.

The Condensation Cycle

A honey dryer operates on a closed-loop condensation principle, much like a modern dehumidifier.

Warm, dry air is circulated over the honey. This air is just warm enough to encourage evaporation without "cooking" the honey.

As the air absorbs moisture from the honey, it becomes humid. This moist air is then drawn over a cold evaporator coil.

The temperature drop forces the water to condense out of the air, which is collected and drained away. The now-dry air is slightly reheated and sent back to continue the cycle.

Maximizing Surface Area with Slow Rotation

The genius of the design lies in its use of slowly rotating plates or discs, which spin at a very low speed (up to 9 revolutions per minute).

These discs pick up a thin film of honey as they rotate. This dramatically increases the surface area of the honey exposed to the dry air, which significantly accelerates the evaporation process.

The slow, deliberate movement ensures the honey is not agitated or aerated, which could introduce unwanted air bubbles or alter its texture. It is a process of exposure, not churning.

A Controlled, Low-Temperature Environment

The entire system is designed to maintain a consistent, low-temperature environment. By reusing the air in a closed loop, the machine has precise control over the temperature and humidity.

This prevents the heat damage that is the primary cause of "spoilage" in the sense of quality degradation. The goal is to remove water, not to heat the honey itself.

Understanding the Trade-offs

While effective, this method is a deliberate choice that involves specific trade-offs compared to other approaches.

Time vs. Quality

The primary trade-off is speed. This gentle, low-temperature process is inherently slower than methods that use high heat. The benefit, however, is a superior final product that retains the characteristics of raw honey.

Mechanical Complexity

A honey dryer is a specialized piece of equipment with a heat pump, motor, and internal platters. This represents a greater initial investment and more mechanical complexity than simple passive dehydration methods.

Energy Consumption

Operating the heat pump and the motor requires a consistent energy source. While the closed-loop system is efficient, it is an active process that consumes electricity, unlike passive methods that rely solely on ambient air.

Making the Right Choice for Your Goal

Ultimately, using a honey dryer is a decision based on your primary objective for the final product.

- If your primary focus is preserving raw honey qualities: This is the ideal method for safely lowering water content without damaging the delicate enzymes and volatile compounds that define high-quality honey.

- If your primary focus is standardizing a large harvest: A dryer provides a reliable way to ensure your entire batch has a consistent, safe moisture level (typically below 18%) for long-term storage and sale.

- If your primary focus is salvaging high-moisture honey: This technology is exceptionally effective at saving a harvest that was extracted "wet" or came from a high-humidity nectar flow, preventing fermentation.

It is an investment in control, allowing you to perfect the final water content while preserving the natural integrity of the honey.

Summary Table:

| Prevention Method | How It Works | Key Benefit |

|---|---|---|

| Gentle, Low-Temperature Drying | Uses warm, dry air in a closed loop to evaporate water without high heat. | Preserves delicate enzymes, flavor, and aroma. |

| Condensation Cycle | Moist air is cooled, forcing water to condense and drain away. | Prevents fermentation by reliably lowering moisture below 18%. |

| Slow-Rotating Discs | Increases honey's surface area for efficient evaporation without agitation. | Maintains texture and prevents aeration for a superior final product. |

Ready to perfect your honey harvest and ensure premium quality?

For commercial apiaries and beekeeping equipment distributors, achieving consistent, high-quality honey is essential for your brand and profitability. HONESTBEE supplies the professional-grade honey dryers and beekeeping equipment you need to standardize your process, prevent spoilage, and maximize the value of every batch.

Contact our wholesale experts today to discuss how our solutions can help you preserve the natural integrity of your honey and scale your operations efficiently.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Natural Wood Honey Dipper for Tea Coffee and Desserts

People Also Ask

- Does honey draw out moisture? The Science of Honey's Hygroscopic Nature

- What is the process for using a dehumidifier to lower honey's moisture content? Expert Drying Techniques

- What methods are employed to reduce the moisture content in honey? Advanced Techniques for Quality Preservation

- What role does a variable frequency fan play in optimizing honey drying? Achieve Precise Moisture Control

- How do specialized honey dryers prevent the increase of HMF content? Preserve Freshness with Low-Heat Technology

- What is the ideal moisture content for honey? A Guide to Perfect Honey Stability

- Why is industrial dehydration equipment necessary for honey preservation? Stop Fermentation and Ensure Stability

- How are the honey's aroma and flavor preserved during the drying process? Master the Art of Flavor Retention