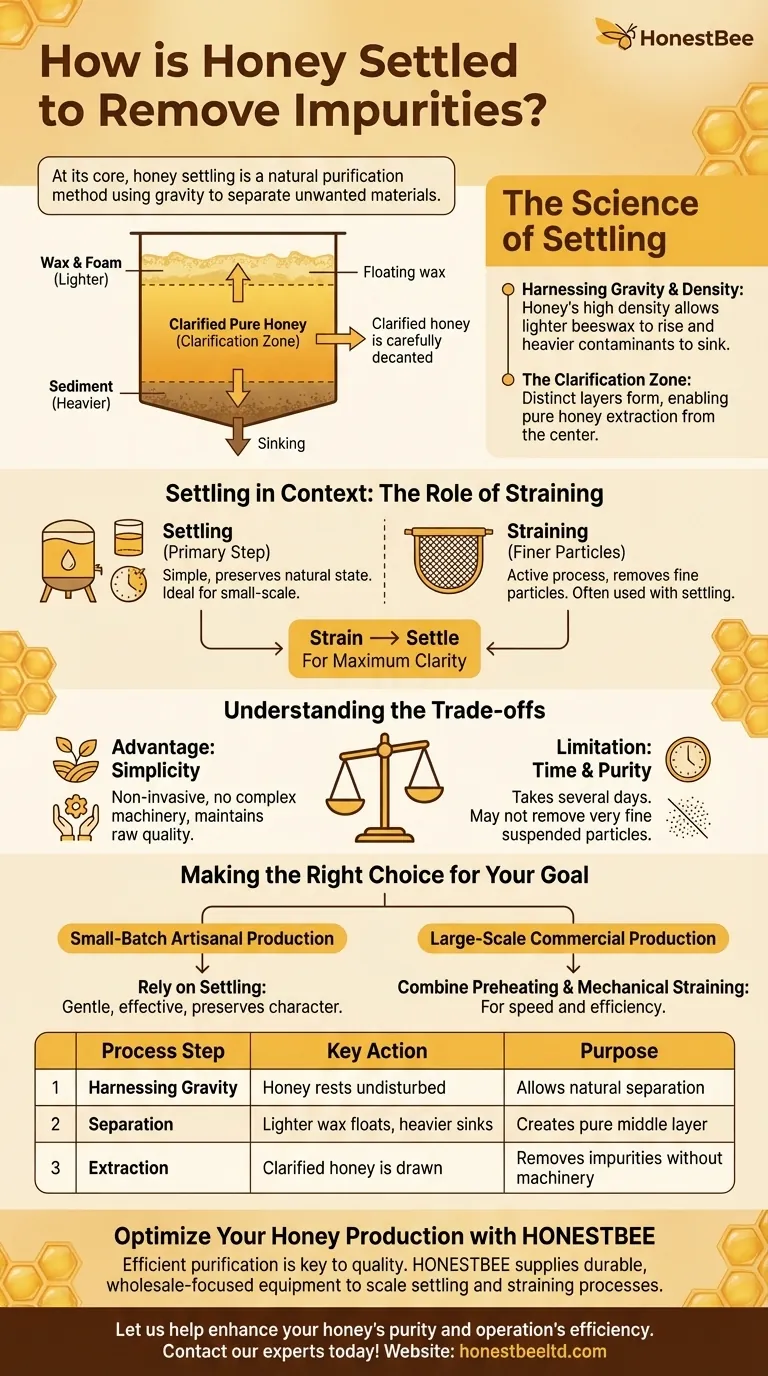

At its core, honey settling is a natural purification method that uses gravity to separate unwanted materials from the honey. After extraction, honey is left undisturbed in a tank, allowing lighter particles like wax to float to the surface and heavier debris to sink to the bottom, leaving pure honey in the middle.

The essential principle behind settling is density difference. Because honey is significantly denser than wax and many other common impurities, it provides a medium where these materials naturally separate over time without mechanical force.

The Science of Settling

Harnessing Gravity and Density

Honey is a supersaturated sugar solution, making it very dense. This high density is the key to the entire settling process.

Particles less dense than the honey, such as small bits of beeswax, will slowly rise to the top.

Conversely, any contaminants that are denser than the honey, like certain types of debris, will gradually sink to the bottom of the settling tank.

The Clarification Zone

This natural separation creates three distinct layers within the tank: a top layer of wax and foam, a bottom layer of sediment, and a large middle layer of clarified, pure honey.

The clean honey is then carefully decanted or drawn off from the middle section, leaving the impurities behind.

Settling in Context: The Role of Straining

Settling as a Primary Step

For many small-scale or artisanal beekeepers, settling is a primary method for clarification. It is simple, requires minimal equipment, and preserves the honey's natural state.

Straining for Finer Particles

Straining is a more active process that physically filters honey through a mesh, cloth, or screen. This is often used to remove finer particles that might not separate effectively through settling alone.

In many operations, settling and straining are used together. Honey might be strained first to remove large debris, then settled for a finer clarification.

Understanding the Trade-offs

The Advantage of Simplicity

The primary benefit of settling is its non-invasive nature. It requires no complex machinery and relies entirely on a natural process, which is ideal for maintaining the raw qualities of the honey.

The Limitation of Time and Purity

The main drawback of settling is time. Depending on the temperature and viscosity of the honey, the process can take several days to complete effectively.

Furthermore, settling may not remove very fine, suspended particles that are close in density to the honey itself, which is why some producers also use straining for maximum clarity.

Making the Right Choice for Your Goal

The best method for clarification depends entirely on the scale of your operation and your desired outcome.

- If your primary focus is small-batch, artisanal production: Relying on settling as your main purification method is gentle, effective, and preserves the honey's natural character.

- If your primary focus is large-scale commercial production: Combining preheating with mechanical straining is necessary for the speed and efficiency required to process large volumes of honey.

Ultimately, understanding how settling works empowers you to choose the right purification technique for your specific needs.

Summary Table:

| Process Step | Key Action | Purpose |

|---|---|---|

| Harnessing Gravity | Honey rests undisturbed in a tank. | Allows natural separation by density. |

| Separation | Lighter wax floats; heavier debris sinks. | Creates a pure middle layer of honey. |

| Extraction | Clarified honey is drawn from the center. | Removes impurities without machinery. |

Optimize Your Honey Production with HONESTBEE

Whether you run a small artisanal apiary or are a large-scale beekeeping equipment distributor, efficient purification is key to quality. HONESTBEE supplies commercial apiaries and distributors with the durable, wholesale-focused beekeeping supplies and equipment needed to scale your settling and straining processes effectively.

Let us help you enhance your honey's purity and your operation's efficiency. Contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What are the size and power variations in honey extractors? Optimize Your Harvesting Efficiency

- What makes automated honey extractors adaptable to different beekeeping needs? Precision Tuning for Commercial Success

- Why is high-efficiency commercial honey harvesting equipment required for high-yield forests? Maximize Your Annual Yield

- Why are honey extractors utilized in the large-scale cultivation of Apis cerana? Boost Yield and Protect Bee Energy

- What are the core functions of an industrial 12-frame honey extractor? Boost Efficiency and Hive Resource Conservation