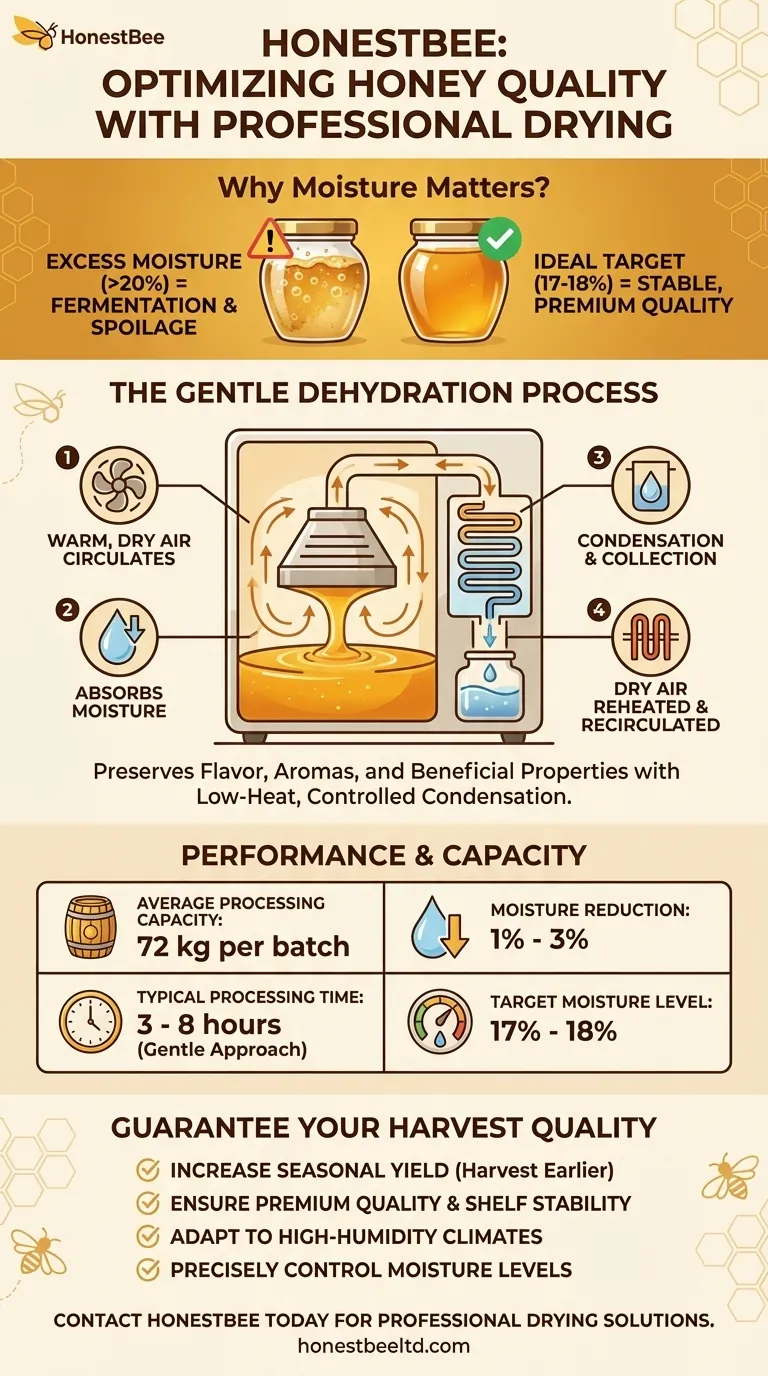

On average, a honey dryer can process 72kg of honey, reducing its moisture content by approximately 1-3%. The time required for this process varies, typically falling within a 3 to 8-hour window, depending on the honey's initial moisture level and the desired final result. This controlled dehydration is essential for producing stable, high-quality honey.

The core problem with honey is that excess moisture—anything above 20%—can lead to fermentation and spoilage. A honey dryer solves this by using a gentle condensation process to remove water without high heat, preserving the honey's delicate flavors, aromas, and beneficial properties.

Why Moisture Content is Critical for Honey Quality

Honey is a supersaturated sugar solution, and its water content is the single most important factor for its stability. Beekeepers and processors must manage this with precision.

The Ideal Moisture Level

The optimal moisture content for finished honey is between 17% and 18%. This level ensures the honey is viscous and stable, preventing the growth of wild yeasts that are naturally present.

The Danger of Excess Water

When moisture content exceeds 20%, these dormant yeasts can become active, leading to fermentation. This not only spoils the flavor but also disqualifies the product from being sold as quality honey.

How a Dryer Increases Your Harvest

A honey dryer increases productivity by giving you more control. It allows you to harvest honey earlier in the season, even before the bees have fully capped the cells, and then bring the moisture down to a safe level mechanically. This can significantly increase your total yield per season.

The Gentle Dehydration Process Explained

Unlike aggressive heating methods that can damage honey, a professional dryer uses a more sophisticated and gentle technique.

How Condensation Works

The system operates on a condensation principle, much like a dehumidifier.

- Warm, dry air is circulated over the surface of the honey, absorbing moisture.

- This now-moist air is drawn away and passed over a cold evaporator.

- The water condenses out of the air and is collected in a vessel.

- The newly dried air is slightly reheated and recirculated back over the honey to repeat the cycle.

Preserving Flavor and Aroma

This low-and-slow method is critical for quality. By avoiding excessive heat, the dryer protects the sensitive substances, enzymes, and volatile aromatic compounds that give honey its unique character. A sealing cover further helps to retain these aromas during the process.

Understanding Performance and Trade-offs

The performance of a honey dryer is not a single number but a range that depends on your specific conditions and goals.

Processing Capacity

Most standard professional units are designed to handle a specific batch size, with 72kg being a common capacity. It's crucial to match the unit's capacity to your typical batch size for efficient operation.

The Rate of Moisture Reduction

The claim of reducing moisture by 1-3% is a realistic benchmark. Starting with very wet honey in a humid environment will result in a slower process, likely closer to the 1-2% reduction over 8 hours. Drier conditions may allow for a faster 2-3% reduction in as little as 3 hours.

The Time Investment

Patience is a key part of the process. The 3 to 8-hour timeframe reflects a gentle approach. Rushing the process with higher temperatures would compromise the very quality you are trying to protect. The time required is a trade-off for preserving the honey's natural integrity.

Making the Right Choice for Your Goal

A honey dryer is an investment in quality control. Use these points to determine if it aligns with your operational needs.

- If your primary focus is maximizing seasonal yield: A dryer is invaluable, as it lets you harvest honey frames before they are fully capped, increasing your turnaround.

- If your primary focus is ensuring premium quality and shelf stability: A dryer provides the precision needed to consistently hit the 17-18% moisture target, preventing fermentation.

- If you operate in a high-humidity climate: A dryer is often a necessity, offering control over moisture levels that the natural environment cannot provide.

Ultimately, a honey dryer is a professional tool for guaranteeing that every batch you produce is stable, delicious, and of the highest possible quality.

Summary Table:

| Metric | Specification |

|---|---|

| Average Processing Capacity | 72 kg per batch |

| Moisture Reduction | 1% - 3% |

| Typical Processing Time | 3 - 8 hours |

| Target Moisture Level | 17% - 18% |

Guarantee the Quality and Stability of Your Honey Harvest

For commercial apiaries and distributors, inconsistent moisture content is a direct threat to your product's quality and profitability. HONESTBEE provides the professional-grade honey drying equipment you need to precisely control moisture levels, prevent fermentation, and ensure every batch meets the highest standards.

Our wholesale-focused operations are designed to support your business with reliable, efficient beekeeping supplies and equipment.

Contact HONESTBEE today to discuss how our honey drying solutions can enhance your yield and protect your brand's reputation.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- How does a honey dryer remove moisture from honey? Achieve Perfect Honey Stability with Controlled Drying

- How to reduce moisture level in honey? Preserve Quality and Prevent Fermentation

- What are some methods to prevent fermentation in high-moisture honey? Protect Your Honey's Quality and Value

- What are some tips for preventing excess moisture in honey during harvesting? Essential Steps for a Stable Harvest

- How does temperature regulation help in managing honey moisture content? Prevent Fermentation & Ensure Quality