For beekeepers using their honey extractor multiple times a year, the rule is simple: a full, deep cleaning is only essential after the final use of the season. If you plan to use the extractor again within the next 5 to 7 days, a complete wash-down is often unnecessary and you can perform a much quicker maintenance clean.

The core principle is not about cleaning for the sake of it, but about preventing spoilage and contamination. The short window between extraction sessions—less than a week—is generally not long enough for the residual honey to ferment or mold, allowing for a more efficient workflow during the busy harvest season.

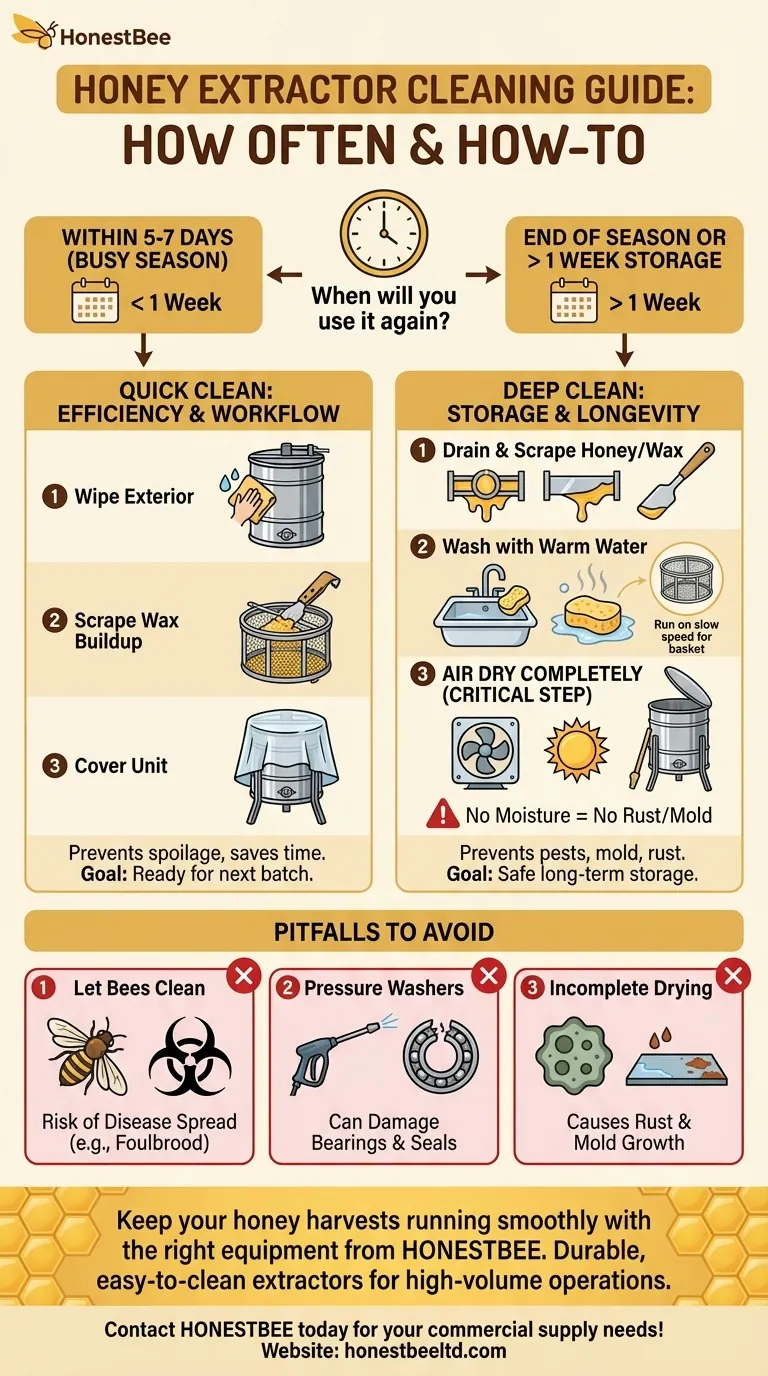

The Guiding Principle: Time Between Uses

The decision to perform a quick wipe-down versus a full deep clean hinges entirely on how long the extractor will sit idle. Understanding the "why" behind this rule empowers you to make the right choice for your equipment and your honey.

When a Full Deep Clean is Essential

A thorough cleaning is mandatory at the end of the harvesting season or if the extractor will be stored for more than a week.

Leftover honey and wax residue will attract pests, and the moisture content in the honey can lead to fermentation or mold growth over time. Proper cleaning and drying are critical for preventing rust and ensuring the extractor is hygienic for the next season.

When a Quick Clean is Sufficient

If you are processing multiple batches of honey over a few consecutive days or within a single week, a full wash is not required.

The small amount of honey left inside will not spoil in this short timeframe. Simply covering the extractor is enough to keep it clean and ready for the next batch, saving you considerable time and effort.

The Correct Cleaning Protocol

Your cleaning method should match your goal. A quick clean maintains workflow during a busy harvest, while a deep clean prepares the equipment for safe, long-term storage.

The Quick Clean: For Use Within 5-7 Days

This process is about tidying up, not a full sterilization.

Use a damp cloth with cool or warm water to wipe down the exterior of the extractor, removing any honey drips or dust.

Scrape any significant wax buildup from the interior walls or basket. Cover the extractor with its lid or a clean sheet to keep it free of dust until the next use.

The Deep Clean: For End-of-Season Storage

This is a more involved process to ensure your equipment is perfectly clean and dry for storage.

First, tilt the extractor to drain as much residual honey as possible. Use a spatula or hive tool to scrape out any remaining wax and propolis from the interior basket and walls.

Next, add warm water to the extractor drum. Warm water is key as it easily dissolves sticky honey and softens wax residue. Use a cloth or soft brush to wash the interior.

For hard-to-reach areas, you can fill the bottom with a few inches of water, close the honey gate, and run the extractor on a slow speed. The spinning action will use the water to clean the entire basket.

Finally, open the honey gate to drain all the water. Drying is the most critical step. Allow the extractor to air dry completely, propping it upside down if necessary, to prevent any rust or mold from forming in storage.

Common Pitfalls to Avoid

While other cleaning methods exist, they come with significant trade-offs that can compromise your equipment or the health of your bees.

The "Let the Bees Clean It" Method

Some beekeepers leave equipment out for the bees to clean. While effective, this is widely discouraged because it can rapidly spread diseases like American Foulbrood between colonies if one hive is infected.

Using Pressure Washers

A pressure washer may seem like an efficient solution, but it can be too aggressive. The high pressure can damage the extractor's bearings or force water into sealed mechanical parts, leading to premature failure and rust.

Incomplete Drying

Putting an extractor into storage while it is still damp is the most common mistake. Even a small amount of trapped moisture can cause rust on metal components and encourage mold growth, creating a serious hygiene problem for the next season.

Making the Right Choice for Your Goal

Your cleaning strategy should directly support your immediate goal, whether it's speed during the harvest or longevity for your equipment.

- If your primary focus is efficiency during a multi-day harvest: A quick wipe-down of the exterior and covering the unit between uses is all that is required.

- If your primary focus is long-term storage and equipment care: A mandatory deep clean with thorough drying after the final use of the season is non-negotiable.

- If your primary focus is preserving distinct honey flavors: When switching from a dark, strong honey (like buckwheat) to a light, mild one (like clover), a full rinse-out is advisable to prevent flavor contamination.

Properly managing your extractor's cleanliness protects your investment, ensures the quality of your harvest, and sets you up for a successful start next season.

Summary Table:

| Cleaning Type | When to Use | Key Actions |

|---|---|---|

| Quick Clean | Between uses within 5-7 days | Wipe exterior with damp cloth; scrape wax; cover unit. |

| Deep Clean | After final seasonal use or storage >1 week | Drain honey; wash with warm water; air dry completely. |

Keep your honey harvests running smoothly with the right equipment from HONESTBEE.

As a trusted wholesale supplier for commercial apiaries and beekeeping equipment distributors, we provide durable, easy-to-clean honey extractors and other essential supplies designed for high-volume operations. Proper equipment maintenance is key to protecting your investment and ensuring the quality of your honey season after season.

Let our experts help you select the best extractor for your workflow. Contact HONESTBEE today to discuss your commercial beekeeping supply needs!

Visual Guide

Related Products

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- What is the primary function of a Centrifugal Honey Extractor? Boost Production with Efficient Honeycomb Preservation

- How do commercial beekeepers extract honey? Master High-Volume, Automated Honey Harvesting

- What are the technical characteristics and requirements for honey extraction from Himalayan Giant Honey Bee honeycombs?

- What are the characteristics, benefits, and drawbacks of manual honey extractors? The Ultimate Guide for Small Apiaries

- What should beekeepers consider before pulling supers for harvest? A Guide to a Successful, Responsible Harvest

- What key features are required for industrial honey extraction equipment? Optimize Your High-Frequency Harvests

- What role do industrial-grade centrifugal honey extractors play? Efficiency & Purity for High-Volume Apiaries

- What is the primary role of a centrifuge in the honey extraction process? Maximize Yields & Preserve Wax Combs