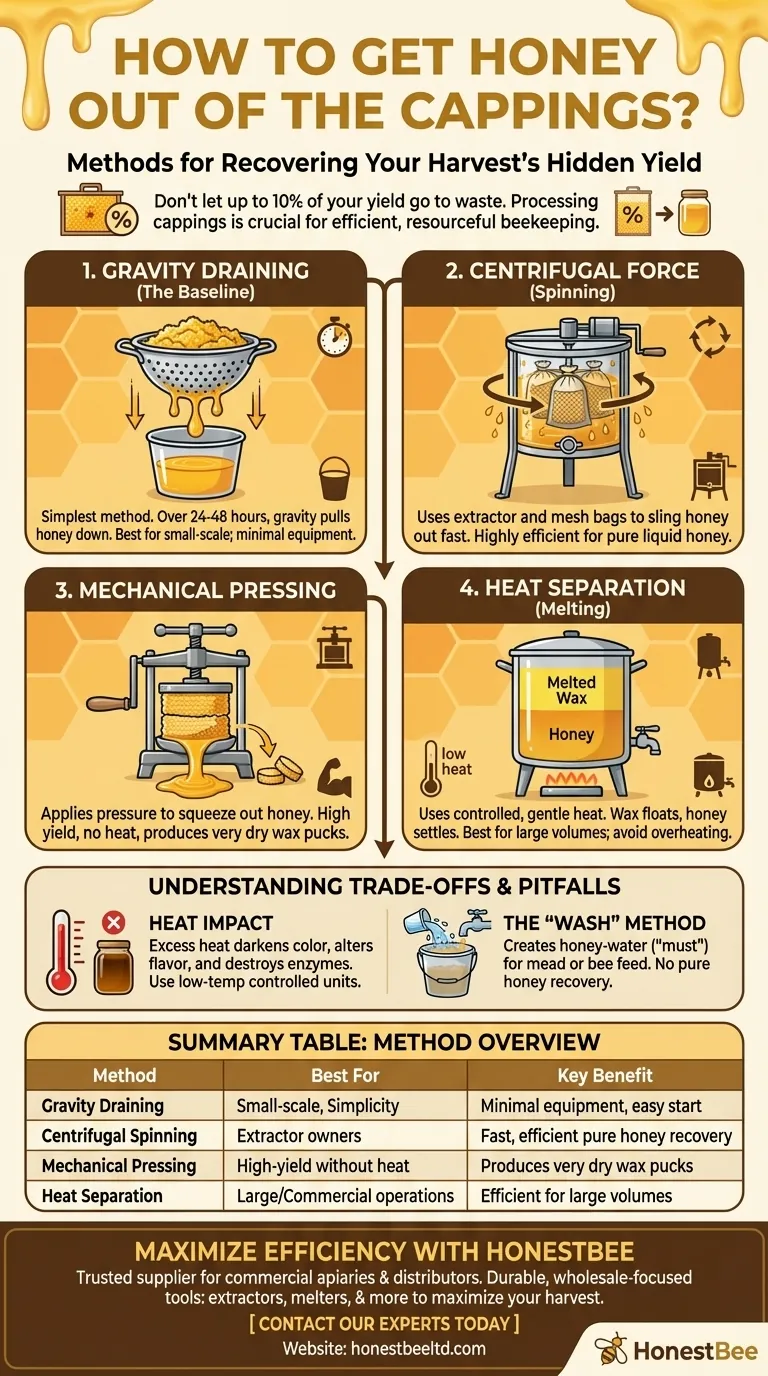

The most common methods to get honey out of wax cappings involve gravity, centrifugal force, pressure, or gentle heat. For small-scale beekeepers, letting the cappings drain through a filter is the simplest starting point, while larger operations often use specialized equipment like spinners or heated melters to maximize their yield efficiently.

The core challenge isn't just removing the honey, but doing so in a way that matches your scale, equipment, and goals for honey quality. Every method involves a trade-off between yield, effort, and the final state of the honey and wax.

Why Recovering Honey from Cappings is Crucial

When you uncap frames to extract honey, the wax cappings that are sliced off are saturated with a significant amount of honey. Simply discarding them is like throwing away a portion of your harvest. Processing these cappings is a vital step for any beekeeper looking to be efficient and resourceful.

The Hidden Yield in Your Harvest

The mixture of wax and honey from uncapping can hold up to 10% or more of your total honey yield. For a small hobbyist, this might be a few extra jars, but for a larger operation, it represents a substantial amount of product that should not be wasted.

The Four Primary Separation Methods

Once you've uncapped your frames using a heated knife, fork, or roller, you are left with a mixture of wax and honey. The next step is to separate them using one of these proven techniques.

Method 1: Gravity Draining (The Baseline)

This is the simplest and most common method, requiring no special equipment beyond a bucket and a filter. Place your cappings into a colander, mesh bag, or a specialized uncapping bucket with a screen, and set it over a food-grade container.

Over the next 24-48 hours, gravity will slowly pull a large portion of the liquid honey down, leaving you with wax that is still wet but much less saturated. This is often the first step, even if you plan to use another method afterward.

Method 2: Centrifugal Force (Spinning)

If you already own a honey extractor, you can use it to process your cappings. Place the cappings into special nylon-mesh bags designed for this purpose.

Spinning the bags inside the extractor uses centrifugal force to sling the honey out of the cappings at a much faster rate than gravity draining. This method is highly efficient for maximizing the recovery of pure, liquid honey.

Method 3: Mechanical Pressing

Using a honey press (which can also be a fruit or cider press) is another effective mechanical method. The cappings are placed inside the press, and pressure is applied to squeeze the honey out.

This technique is excellent for achieving a high yield and results in very dry wax pucks. It's a great option if you want to recover as much honey as possible without applying any heat.

Method 4: Heat Separation (Melting)

For larger or more commercial operations, dedicated uncapping tanks and wax melters are the most efficient tools. These devices use gentle, controlled heat to melt the wax.

Because honey is denser than wax, the liquid wax floats to the top, and the honey settles at the bottom. Spigots at different levels allow you to drain the honey and melted beeswax separately.

Understanding the Trade-offs and Pitfalls

Choosing a method isn't just about efficiency; it's also about understanding the impact on your final products.

The Impact of Heat on Honey Quality

Applying too much heat can be detrimental to honey. It can darken the color, alter the flavor, and destroy the beneficial enzymes that make raw honey so valued. If using a melter, it must be a low-temperature, controlled unit to preserve the honey's quality.

The "Wash" Method: A Different Goal

Some beekeepers choose to simply rinse their cappings with cool water. This does not recover pure honey but instead creates a honey-water solution, often called "must."

This solution is perfect for making mead (honey wine) or can be used as a supplemental feed for your bees. It's a way to ensure nothing goes to waste, even if you don't recover liquid honey.

Equipment Dictates the Method

Your choice is heavily influenced by the equipment you already own. If you have an extractor, spinning is a logical next step. If you are a small-scale hobbyist, gravity draining followed by washing the cappings may be the most practical path.

Choosing the Right Method for Your Apiary

Your decision should be based on your scale, available equipment, and what you want to do with your honey and wax.

- If your primary focus is simplicity and small scale: Start with gravity draining, then wash the remaining wax to make a honey-water solution for mead or bee feed.

- If your primary focus is maximizing pure honey yield with existing tools: Combine gravity draining with spinning the cappings in your extractor using a mesh bag.

- If your primary focus is efficiency at a larger scale: Investing in a dedicated, low-temperature wax melter or uncapping tank will save significant time and labor.

By thoughtfully processing your cappings, you honor the work of your bees and ensure you make the most of every drop of your harvest.

Summary Table:

| Method | Best For | Key Benefit |

|---|---|---|

| Gravity Draining | Small-scale beekeepers, simplicity | Requires minimal equipment, easy to start |

| Centrifugal Spinning | Beekeepers with an extractor | Fast, efficient recovery of pure liquid honey |

| Mechanical Pressing | High-yield recovery without heat | Produces very dry wax pucks |

| Heat Separation | Large/commercial operations | Highly efficient for processing large volumes |

Maximize the efficiency and yield of your apiary with the right equipment from HONESTBEE.

As a trusted supplier for commercial apiaries and beekeeping equipment distributors, we provide the durable, wholesale-focused tools you need—from honey extractors to specialized wax melters—to process your cappings efficiently and maximize your harvest.

Contact our experts today to discuss the best equipment solutions for your operation's scale and goals.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 10L Stainless Steel Honey Wax Press Extractor for Wax Cappings

People Also Ask

- How do water jacket melters function? Achieve Gentle, Scorch-Free Melting for Sensitive Materials

- What happens to beeswax if it is heated beyond 170F? Prevent Irreversible Quality Loss and Darkening

- How does a steam wax melter work? A Fast, Efficient Method for High-Quality Wax

- What is the flashpoint of beeswax? Essential Safety and Quality Tips for Beekeepers

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material