To achieve the most efficient honey extraction, you must begin with fully capped honeycombs, which ensures the honey has the right moisture content. During the process, optimize your extractor's speed to get the most honey out without damaging the combs and use gravity to your advantage by tilting the frames. A clean, well-prepared indoor workspace is non-negotiable to prevent a sticky mess and keep bees from being attracted to the harvest.

True efficiency in honey extraction is not found in a single secret but in a systematic approach. It requires preparing your space and equipment, selecting the right frames, and executing each stage—from uncapping to cleanup—with precision and care.

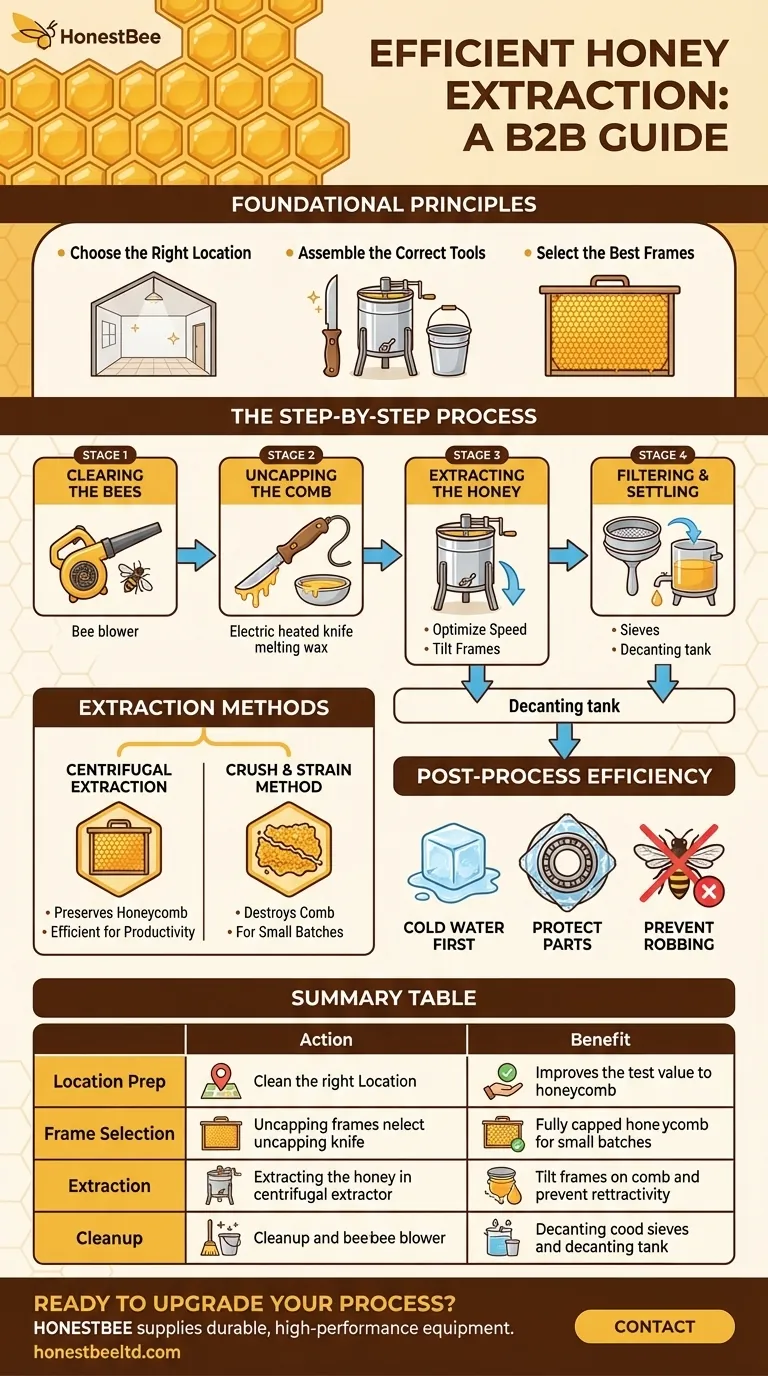

Foundational Principles of Efficient Extraction

Before you bring a single frame of honey inside, setting the stage correctly is the most significant factor in a smooth and efficient process. Overlooking these fundamentals leads to wasted time, lost honey, and unnecessary frustration.

Choose the Right Location

Your extraction space must be indoors and clean. This is a food-safe process, and an enclosed area prevents bees, ants, and other insects from descending on your exposed honey, a phenomenon known as "robbing."

Protect all surfaces from sticky spills. A well-placed tarp or plastic sheeting can save you hours of cleanup.

Assemble the Correct Tools

Efficiency is impossible without the right equipment ready to go. Before you begin, ensure you have everything assembled, including an uncapping knife or roller, a tank or bucket to catch the cappings, the honey extractor itself, and food-grade buckets with filters or cheesecloth for the finished product.

Select the Best Frames

Only extract honey from frames where the cells are fully capped with wax. The bees cap the honey only when it has been fanned down to the correct moisture content (under 18.6%).

Harvesting uncapped honey can lead to fermentation and spoilage, wasting your entire effort.

The Step-by-Step Extraction Process

Executing the extraction process in a logical sequence minimizes mess and maximizes yield. Each stage builds upon the last, contributing to the overall efficiency of the operation.

Stage 1: Clearing the Bees

Before bringing frames indoors, you must remove the bees. This can be done with a bee brush for a few frames or, more efficiently for larger harvests, with a bee blower or an escape board placed on the hive a day prior.

Stage 2: Uncapping the Comb

The wax cappings must be sliced off to release the honey. An electric heated knife melts through the wax with ease, making it one of the most efficient tools for this job.

Alternatively, an uncapping roller or fork can be used to puncture the cappings. The goal is to open the cells with minimal damage to the comb structure.

Stage 3: Extracting the Honey

Place the uncapped frames into your centrifugal extractor. Optimize the speed by starting slowly to allow the initial weight of the honey to come out without breaking the delicate wax comb.

Gradually increase the speed for a thorough extraction. For tangential extractors, you will need to flip the frames and repeat the process. In any extractor, tilting the frames slightly can help gravity pull out the last few drops.

Stage 4: Filtering and Settling

Once extracted, the honey must be filtered to remove wax particles and other debris. Run the honey through a series of sieves or filters into a bottling bucket.

For the highest quality, allow the filtered honey to sit for a day or two in a process called decanting. This allows the finest particles and air bubbles to rise to the surface, where they can be skimmed off before bottling.

Understanding the Trade-offs: Extraction Methods

The method you choose has a direct impact on your efficiency, investment, and the future productivity of your hives.

Centrifugal Extraction

This method, using a manual or motorized extractor, is the standard for most beekeepers. Its primary advantage is that it preserves the honeycomb. Bees expend significant energy to build comb, so returning it to them intact allows them to focus on making more honey. This is the most efficient method for long-term hive productivity.

The Crush and Strain Method

This technique involves crushing the entire honeycomb and straining the honey from the wax. It requires no expensive equipment, making it highly accessible for beginners or those with foundationless combs. However, it destroys the comb, forcing the bees to rebuild it from scratch, which is a significant setback in energy and time for the colony.

Post-Process Efficiency: Cleaning Your Equipment

Your work isn't done when the honey is in the bucket. Efficient cleanup protects your equipment and prevents future problems.

Use Cold Water First

Always begin washing your extractor and tools with cold water. Hot water will instantly melt any remaining wax, smearing it into a stubborn film that is very difficult to remove. Cold water washes away the honey and solidifies the wax for easy scraping.

Protect Sensitive Parts

If your extractor has an exposed lower bearing, cover it with plastic wrap before washing to prevent rust and damage.

Prevent Robbing and Disease

Never leave your equipment outside for the bees to "clean up." This can incite robbing behavior between hives and can rapidly spread diseases like American Foulbrood if any spores are present in the honey.

Making the Right Choice for Your Operation

Your approach should align directly with your goals as a beekeeper.

- If your primary focus is maximizing long-term hive productivity: Invest in a centrifugal extractor to preserve your valuable drawn combs.

- If your primary focus is a small-batch harvest with minimal investment: The crush and strain method is a perfectly viable and effective starting point.

- If your primary focus is maintaining honey quality and hygiene: Ensure you always work in a clean, indoor space and allow time for proper filtering and settling.

Ultimately, an efficient honey harvest is the result of a deliberate and well-executed plan from start to finish.

Summary Table:

| Key Step | Action | Benefit |

|---|---|---|

| Location Prep | Use a clean, indoor space | Prevents robbing, ensures hygiene |

| Frame Selection | Harvest only fully capped frames | Prevents fermentation, ensures quality |

| Extraction | Optimize speed, tilt frames | Maximizes yield, protects honeycomb |

| Cleanup | Wash with cold water first | Easily removes wax, protects equipment |

Ready to upgrade your honey extraction process?

As a commercial beekeeper or distributor, your efficiency directly impacts your bottom line. HONESTBEE supplies the durable, high-performance equipment—from extractors to uncapping knives—that professional operations rely on for a seamless and profitable harvest.

Contact our wholesale team today to discuss your needs and get a quote. Let us help you build a more efficient and productive beekeeping business.

Visual Guide

Related Products

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What are the advantages of manual centrifugal honey extractors? Ensure Precision in Your Honey Yield Statistics

- What are the advantages and disadvantages of a manual honey extractor? Essential Guide for Small-Scale Beekeeping

- How do you extract honey by hand? A Guide to Crush & Strain vs. Manual Extractor

- What are the characteristics and benefits of a manual honey extractor? The Perfect Choice for Hobbyists

- What are the features of a manual honey extractor? Explore Top Benefits for Small-Scale Beekeeping