The primary advantages of a condensation honey dryer are its ability to gently reduce moisture content while preserving the honey's delicate enzymes, flavor, and aroma. By operating at low temperatures within a closed system, it achieves high energy efficiency and low operating costs, allowing producers to increase their harvest volume without compromising the premium quality of their final product.

A condensation dryer is more than just a tool for removing water; it is a strategic investment in quality control and operational flexibility. It empowers beekeepers to harvest honey based on hive readiness, not just weather conditions, ensuring a consistent, high-value product every season.

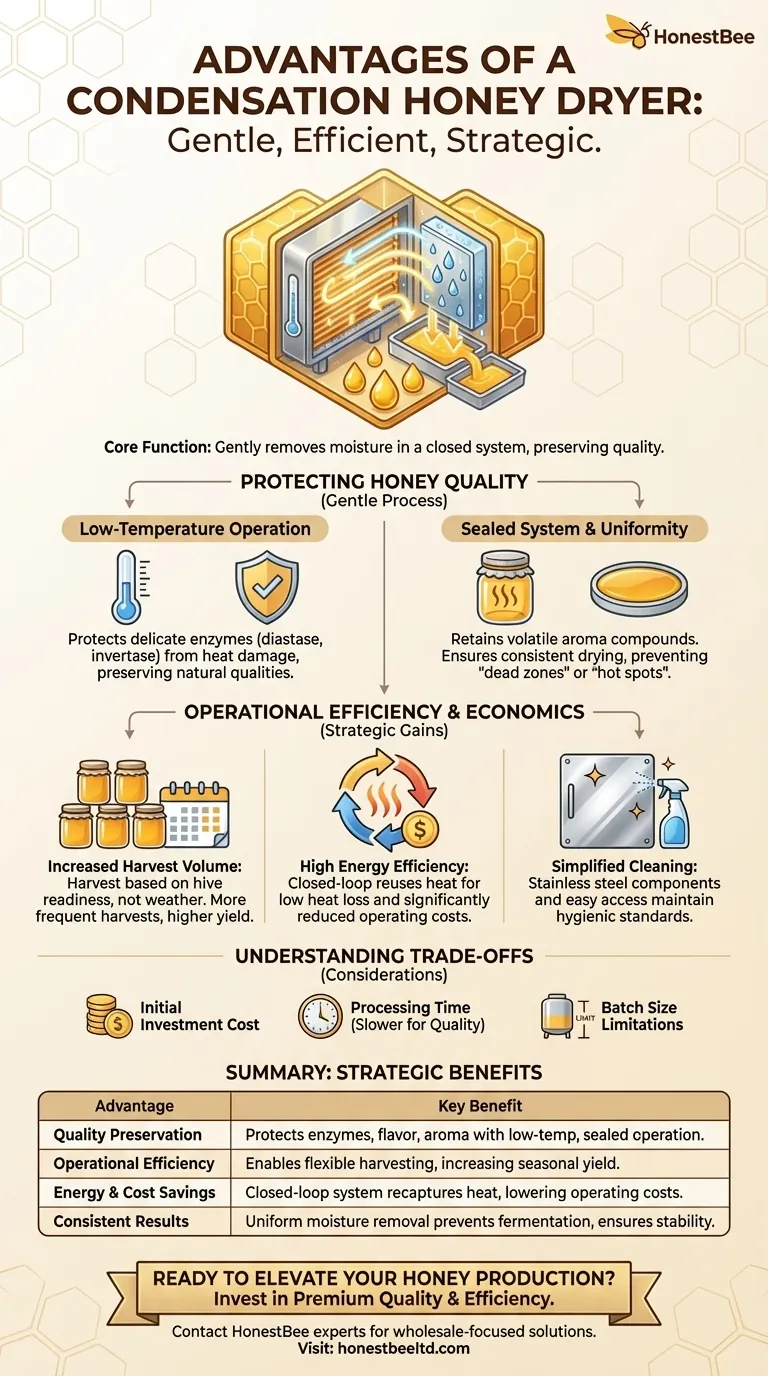

How Condensation Drying Protects Honey Quality

The core function of a condensation dryer is to remove excess water, which is critical for preventing fermentation and ensuring long-term stability. However, how it removes that water is what sets it apart and protects the value of your honey.

Low-Temperature Operation

Heat is the enemy of raw honey. Excessive temperatures destroy beneficial enzymes like diastase and invertase, and can alter the delicate flavor profile.

Condensation dryers operate at a low, controlled temperature. This gentle process ensures these sensitive substances remain intact, preserving the honey's natural, raw qualities that consumers value.

Sealed System for Aroma Preservation

Much of honey's unique character comes from volatile aromatic compounds. Open-air drying or high-heat methods cause these compounds to evaporate along with the water, permanently dulling the honey's aroma and flavor.

A condensation dryer uses a closed air circulation system. This means the air is continuously dehumidified and recirculated within the chamber, trapping and retaining the honey's natural bouquet.

Gentle and Uniform Moisture Removal

Inconsistent drying can create "dead zones" where some honey remains too moist, or "hot spots" where other honey gets overheated.

These dryers are engineered with a large heat transfer area to ensure the entire batch is treated uniformly. This consistency guarantees that every drop of honey reaches the target moisture level without being damaged.

The Impact on Operational Efficiency

Beyond quality, a condensation dryer introduces significant improvements to the workflow and economics of honey production.

Increased Harvest Volume

Beekeepers are often forced to wait for dry weather or for bees to slowly reduce the honey's moisture content in the hive. This can limit the number of harvests possible in a season.

By allowing you to dry honey after it's been removed from the hive, you can harvest earlier and more often, even if the nectar flow produces high-moisture honey. This directly increases your potential yield per season.

High Energy Efficiency

Traditional dehydrators often vent hot, moist air to the outside, constantly consuming energy to heat new, incoming air.

The closed-loop system of a condensation dryer is inherently efficient. It recaptures energy by cooling the air to condense the water, then reheats that same dry air to continue the process, resulting in low heat loss and significantly reduced operating costs.

Simplified Cleaning and Maintenance

Food processing equipment must be easy to sanitize. These dryers are typically built with stainless steel components and designed for easy access, which simplifies cleaning and helps maintain hygienic standards.

Understanding the Trade-offs

No technology is without its considerations. An objective assessment requires acknowledging the potential limitations.

Initial Investment Cost

A specialized piece of equipment like a condensation honey dryer represents a significant upfront capital investment compared to simpler, passive drying methods. This cost must be weighed against the long-term gains in quality and productivity.

Processing Time

The gentle, low-temperature process is effective but not instantaneous. A typical cycle might reduce moisture content by 1-2% over an 8-hour period. This is a deliberate trade-off of speed for quality, as faster, high-heat methods would damage the honey.

Batch Size Limitations

Each dryer has a specific capacity. For very large commercial operations, the batch nature of these systems may become a bottleneck, potentially requiring multiple units to keep up with harvest volumes.

Making the Right Choice for Your Operation

Deciding whether to invest in a condensation dryer depends on your specific goals as a producer.

- If your primary focus is premium quality and flavor preservation: A condensation dryer is the ideal choice for producing raw honey that commands a higher price.

- If your primary focus is increasing harvest volume and consistency: The ability to manage moisture post-harvest gives you control over your production schedule and maximizes your yield.

- If your primary focus is long-term operational cost: The high energy efficiency of the closed-loop system provides a clear advantage, reducing electricity consumption over the life of the unit.

Ultimately, a condensation honey dryer is a tool that grants you precise control over the final, critical step of your honey production process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Quality Preservation | Protects delicate enzymes, flavor, and aroma with low-temperature, sealed operation. |

| Operational Efficiency | Enables harvesting based on hive readiness, not weather, increasing seasonal yield. |

| Energy & Cost Savings | Closed-loop system recaptures heat, leading to low operating costs. |

| Consistent Results | Uniform moisture removal prevents fermentation and ensures product stability. |

Ready to elevate your honey production?

A condensation honey dryer is a strategic investment for commercial apiaries and distributors focused on premium quality and operational efficiency. At HONESTBEE, we supply the professional beekeeping equipment you need to maximize your harvest volume and protect your product's value.

Contact our experts today to discuss how our wholesale-focused solutions can benefit your operation.

Visual Guide

Related Products

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- Why is Postharvest Drying Equipment critical in the stingless bee honey supply chain? Prevent Spoilage & Boost Quality

- What is the primary role of industrial mechanical dehumidification equipment in the production of immature honey?

- What is the ease of use of the honey dryer's controller? Master Honey Drying with Intuitive Control

- How does the design of the honey dryer enhance the drying process? Achieve Gentle, Efficient Honey Stabilization

- Why is moisture control important during honey drying? Prevent Fermentation & Ensure Quality

- How do industrial heating and dehumidification processes control Small Hive Beetle? Expert SHB Sterilization Guide

- How to dry up honey? The Safe Guide to Stabilizing Honey and Preventing Fermentation

- How do professional honey dehydration and homogenization equipment contribute to the quality stability of honey products?